In mechanical engineering and metalworking it is impossible to do without precise measuring instruments. Verification plates (measuring planes) and standard rulers are one of the oldest tools used to control the planes of products and parts. In addition to control, the surface plate is used:

- as a surface of zero points (base) for installing measuring instruments when making accurate measurements;

- for setting up (adjusting) measuring instruments;

- when marking blanks and parts.

The industry produces measuring planes ranging in size from 250×250 to 2500×1600 mm in five different designs. The execution number depends on the geometric dimensions of the slab, the material used and the design.

The main regulatory document defining the requirements for testing and lapping plates is GOST 10905-86. According to the state standard, there are 6 accuracy classes of measuring and calibration tools: 000, 00, 0, 1, 2, 3. Additional accuracy classes 4 and 5 are assigned to plates that have been in operation or have undergone repair. The characteristic that determines the accuracy of the measuring planes is the tolerance (deviation), expressed in microns. For slabs of the same class, but of different sizes, the tolerance values are different.

Measuring instruments belonging to accuracy classes 000 and 00 are used in metrology laboratories as standards. Measurements using high-precision surfaces are made at a strictly defined temperature and humidity in the room.

Purpose of the metric device

The calibration plate is used to measure the accuracy of dimensional and plane parameters of parts and mechanisms.

The device is often used to adjust mechanisms in order to combine two indicators: accuracy of execution and adjustment of the operating parameters of mechanisms. Thanks to the flat base surface, the metric device is a setting measuring tool for parts or mechanisms. Among the large list of offers from instrument-making companies, the most popular and most expensive are standard and precision calibration plates made of precious metal, high-alloy alloys and semi-precious polished stone of increased strength.

The main condition for accurate measurements is to install the equipment on a flat, solid base (table, cabinet, workbench) in a thermostated insulated box.

https://youtube.com/watch?v=ugW3nu0EVFU

Description

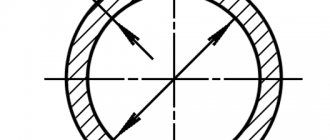

The principle of operation of calibration and marking cast iron plates is based on measuring deviations from the straightness and flatness of the surface.

Cast iron calibration and marking plates are produced in the following versions:

1- with manual scraping of working surfaces;

2- with machined working surfaces.

Slabs measuring 630*400 mm or less have three support points, and slabs measuring over 630*400 mm have at least five supports.

A general view of the cast iron calibration and marking plates is shown in Figures 1 and 2.

Types of testing plates

GOST 17232-99 plates made of aluminum and aluminum alloys.

technical specifications For the manufacture of reference measuring planes, three types of materials are used:

Glass reference planes were used in the USA and other countries until the 1950s. The widespread use of inexpensive glass measuring instruments was explained by the increased needs of mechanical engineering during the Second World War. Glass calibration planes were made by grinding followed by polishing. The result was products with high metrological characteristics. The advantages of flat surface glass standards include high hardness, chemical resistance, a relatively low coefficient of thermal expansion, and the absence of internal stresses. Unlike cast iron, minor damage to glass products does not result in burrs. The main disadvantage of glass was its fragility. This circumstance became the reason for the rejection of surface plates made of this material.

Historically, the most common type of calibration planes in the USSR and Russia are cast iron calibration plates. The choice of cast iron as a structural material for the manufacture of measuring surfaces is determined by the high strength and relative cheapness of the metal. For the manufacture of measuring plates, fine-grained dense cast iron with a hardness of 150–210 HB is used. Product blanks are cast in molds, the lower part of which is made of steel. The working surface of the slab is formed from below. To reduce the weight of the product and for resistance to deformation, the structure is equipped with stiffeners.

The cast billets contain significant internal stresses associated with the crystallization of cast iron. If measures are not taken to eliminate stress, products will become deformed during processing and operation. To relieve internal stresses in the metal, castings are subjected to aging. For natural aging, the workpieces are kept for several weeks or months at normal temperatures before processing. To accelerate aging, cast iron is heated in furnaces to 500 degrees and then slowly cooled.

Surface processing of surface plate blanks is carried out on milling, planing and grinding machines. For accuracy classes 1–3, such processing is usually sufficient. Products are finished with higher precision using scraping and calibration.

When manually scraping, three slabs are processed at once. During processing, each of them, in a certain sequence, alternately acts as a standard and a controlled surface. In mechanical engineering, this control method is called the three-plate method.

Quality control of the processing of straight edges and plates is carried out using the spot method. The more spots of paint are obtained upon contact with the standard, the higher the accuracy of surface processing. For example, for surfaces of accuracy classes 0 and 1, there must be at least 25 spots per square inch.

In recent years, the use of granite surface slabs has been increasing. Granite is characterized by high hardness and low expansion coefficient. There are practically no internal stresses in such products. Thanks to these material properties, testing planes made of granite maintain accuracy for a long time.

Test plate

Test plates are used to check and adjust planes, for markings and other purposes. They are made from well-seasoned cast iron. The working surface of the slab, planed and precisely processed by scraping, is flat. [1]

Test plates and rulers are periodically checked using paint standards or the three-plate method. When using the latter method, one should take into account the possible distortion of the plane as a result of the formation of a hyperbolic paraboloid. To eliminate this error, rectangular slabs are checked by applying a control ruler to them diagonally, thereby detecting raised or lowered corners. [2]

Verification plates and cubes: purposes and advantages

- verification;

- assembly of parts and mechanisms;

- carrying out various types of measurements.

GOST 11648-75 quick-release thrust washers. technical specifications (with change n 1)

A calibration plate, the price of which satisfies the needs of the buyer, has the following advantages:

- not subject to corrosion;

- wear-resistant;

- not affected by acids;

- practically independent of temperature;

- has no electrical or magnetic permeability, and therefore does not require demagnetization;

- the surface plane always clearly corresponds to exactly the accuracy class that you prefer, etc.

Test cube

, in turn, is intended for checking right angles or high-quality control over the perpendicularity of certain surfaces under study. The scope of its application is quite wide and not limited, and therefore it is often used for:

- pattern works;

- metrological control;

- to change the settings of various machines in the production field;

- plumbing and assembly work, etc.

It is worth noting that previously it was customary to make calibration cubes from high-quality steel, but such a cube had several disadvantages, the main one of which was its weight, which, given the large size of the cubes, could be beyond the strength of one person. Today in the assortment of our online store you will find a hard stone calibration cube, since such a product has a number of undeniable advantages:

- low coefficient of thermal expansion;

- high hardness;

- not susceptible to corrosion;

- maximum accuracy and minimum error;

- wear resistance, etc.

Many specialists who use products of this type in their work have already managed to appreciate all the prerogatives that can be obtained by using just such cubes and slabs, which you can buy today at a fairly affordable price and on favorable terms.

Verification

GOST 10597-87 paint brushes and brushes. technical specifications (with change n 1)

carried out according to the document MI 2007-89 “GSI. Testing and marking plates. Verification methodology”, approved by the All-Union Scientific Research Institute of Metrology of Standard Samples (VNIIMSO) on June 23, 1989.

Basic means of verification:

— metal measuring ruler 1000 mm, registration number in the Federal Information Fund 20048-05;

— surface roughness samples (comparisons) model 1833, registration number in the Federal Information Fund 25019-08;

— 90° calibration square, type УШ, registration number in the Federal Information Fund 666-10;

— probes, registration number in the Federal Information Fund 369-89;

— calibration and marking plate, registration number in the Federal Information Fund 11605-10;

— calibration rulers type ШД, 3 categories according to GOST 8.420-2002, registration number in the Federal Information Fund 3617-10;

— lever-gear measuring head type 1IG, registration number in the Federal Information Fund 2681-70;

— a device for measuring hardness according to the Rockwell method, type TR 5006, registration number in the Federal Information Fund 11286-04.

It is allowed to use similar verification tools that ensure the determination of the metrological characteristics of the verified measuring instruments with the required accuracy.

The verification mark is applied to the SI verification certificate or passport.

Notes

- GOST 10905-86 “Testing and marking plates. Technical conditions."

- MI 2007-89 “Testing and marking plates. Verification methodology."

| Measuring instruments | |

| |

| Micrometers |

|

| GOST ISO | This is a draft article on standardization or metrology. You can help the project by adding to it. |

Choosing slabs

Finishing plates are made from ordinary cast iron scraped surface plates. In this article we are looking at plates for repairing caliper tools, micrometers, bore gauges, pattern squares and rulers, and the like. Plates for finishing gauge blocks are a little different and we won’t talk about it now (although the principle is the same).

We need to select three slabs measuring 400x400 mm. In good condition, preferably new. Without shells and visible inclusions. The slabs are cleaned, washed and sent for grinding; it is desirable that the surface grinding machine is the most accurate. Then the plates are subjected to artificial aging - annealing in a furnace with gradual heating to ~500 degrees Celsius, and gradual cooling along with the furnace. The operation is long... heating at a rate of 60-70 degrees per hour, holding in the oven for ~1.5 hours... cooling for several hours... Many people neglect this. I myself worked with annealed and non-annealed slabs - there was not much difference.

If you age the slabs using this method, you will have to finish sanding again. The slabs are processed with a file and sandpaper - sharp edges and roughness are removed after casting. Use a file to carefully remove the chamfer along the edge of the upper working side. Then everything is thoroughly washed with gasoline, dried, and the entire underside is painted with oil paint. After this, they begin to grind the finishing plates together.

Additionally: since the slabs are really heavy, and the finishing operation will have to be carried out relatively often, it makes sense to make it somewhat easier to remove the metal layer from above and below using a milling machine. This will not harm us, but it will make our overall work much easier!

Platform classes and sizes

Testing equipment is produced with different accuracy classes. For a new device, the calibration accuracy class is determined by the following indicators:

- 000;

- 00;

- 0;

- 1;

- 2;

- 3.

The requirements for used control plates are not as stringent. Due to slight wear of the mounting surface of the testing equipment, deviations in the accuracy class with an indicator of 4 or 5 are allowed.

The dimensions of the installation platform can vary from 250 x 250 mm to 2500 x 1600 mm. The distinctive properties of a metric instrument include marking with design numbers 1, 2, 3, 4 and 5, which determine the method of surface treatment and design of the instrument. The classes of the surface plate are determined by the norms of permissible deviations for the accuracy of surface treatment, the degree of its roughness and the perpendicularity of the side elements.

Metric parameters

A granite calibration slab made of hard material of natural origin is made from varieties of rock: diabase and gabbro with a compression limit of at least 264.0 MPa. Compared to products made of gray metal, the matte granite surface has increased strength, does not reflect light, does not rust, and is not magnetized. The weight and cost of the device depends on the size of the plate and the accuracy class of the measuring scale.

The granite calibration slab is manufactured in the following design: without side grips; with tolerances for deviations along the perpendicularity of the side surface with respect to the installation plane; mutual perpendicularity of the side surfaces, with side grips. The device includes:

- pens;

- adjustable supports;

- lid;

- user manual.

Each device is equipped with a Certificate of Compliance with the European quality standard and the requirements of interstate GOST.

Labeling and packaging of the device for transportation

Each factory-made calibration plate must have a trademark on the side with information about the manufacturer. The label must also indicate:

- accuracy class;

- year of issue;

- serial number;

- state standard.

The product passport must include the certification results and display the state Quality Mark. All surface slabs must be preserved for two years.

In the process of preparing equipment for the conservation process, the surface of the device must be covered with a shield, the device itself is placed in a wooden container covered with steel tape, lined with waterproofing material. Packaged products can be transported in covered vehicles, wagons, containers or trailers with rigid fixation with safety belts.

During transportation, the platforms can withstand vibration with a vibration frequency of up to 120 movements per minute. To store equipment, it is recommended to allocate a dry heated room with a temperature no higher than +40 0 C and air humidity up to 80%. The main condition for maintaining the stove in working condition is the absence of aggressive gases in the air.

Technical tests of the device are carried out once every 3 years and the results are entered into the product passport.

Features of use

The most common use of surface plates is to check straightness and flatness. In the process of checking planes, the light test method or the spot method can be used. Precise measurements and markings of workpieces are made on standard surfaces using thickness measures, dial-type micrometric indicators, gravers, surface gauges and other tools. To perform the above operations, it is necessary to use measuring instruments that exceed the accuracy class of the manufactured parts. It is recommended to use calibration planes entered in the state register and measuring instruments that have been tested according to an approved method.

To maintain the accuracy of surface plates for a long time, they must be protected from wear, shock and harmful environmental influences. When storing, use protective shields or covers made of soft materials. To avoid corrosion, treat cast iron surfaces with machine oil or other types of lubricant.

Device for marking parts

When producing high-precision parts, a marking plate made of fine-grained cast iron is used to mark the workpiece. The bottom side of the device is equipped with stiffening ribs that provide reliable adhesion to the workbench and protect the device from sagging during mechanical loads. Some models of the marking device may have longitudinal and transverse recesses of 3 mm and a width of 2 mm on the front surface.

To obtain the exact dimensions of the future part, the surface of the plate is treated with graphite powder or paint. The imprint on the workpiece is obtained by close contact of the paint with the surface of the future part. The resulting image is cut out along the marking line with minimal deviation in size, and the precision of the part is achieved using metalworking tools.

The marking plate for spatial and plane markings includes a jack, support pads, adjustable wedges, a cast iron square, double wedges, prisms, and cubes. To align the model, a control scale is used on the surface of the device, which allows you to adjust the position of the upper clamping wedge. After marking is completed, the surface of the slab is cleaned with a soft cloth moistened with kerosene or machine oil.

Surface plate: cast iron or granite

Verification slabs today are made, as a rule, from two materials - cast iron and granite. Making a choice is quite difficult and there is a completely logical explanation for this: a cast iron calibration plate and a granite calibration plate practically do not differ in quality and can be used equally successfully in any field. However, many specialists prefer to use granite products in their work, as they have a number of features:

- have a greater margin of safety;

- have highly accurate measurements;

- have minimal wear rates;

- presented in the widest possible range;

- have regulated flatness and roughness indicators;

- have a variable number of supports, which makes their use more convenient;

- have special devices for proper transportation, etc.

Granite surface slabs are more often used in manufacturing and research activities, while cast iron surface slabs are considered more versatile and are widely used in all other areas. The variety of sizes and shapes makes testing surfaces popular and relevant. You can buy calibration plates and calibration cubes in a wide range and on the most favorable terms for you in our online store. We comply with storage and transportation conditions, cooperate with the best domestic manufacturers and guarantee quality, confirmed by certificates of conformity and passports for all products presented in our catalog.

Verification plate - 9. Verification plate (clause 2.5) The basic technical requirements must correspond to those indicated in the table. 21 Table 21 Overall dimensions Tolerance of straightness in any directions, µm for the entire length of measurement local along the length, mm 160 250 Not less than... ... Dictionary of terms of normative and technical documentation

Slab - Slab “a large flat piece of solid material with a smooth surface”, the word is usually considered to be derived from the Greek. plínthos: Slab (structural mechanics) Slab (building part): reinforced concrete slab; building floor slab; stove... ... Wikipedia

TESTING PLATE - cast iron. monolithic rigid box-shaped ribbed structure with precision processing. external plane for checking the flatness of parts and marking work. See fig. Test plate ... Big encyclopedic polytechnic dictionary

PLATE - (1) a flat rectangular (sometimes round) monolithic product made of solid material cast iron, steel, reinforced concrete, stone, etc., the thickness of which is several times less than the width and length, and the working surface (usually one) is flat and smooth (except... ... Big Polytechnic Encyclopedia

GOST 17734-88: Console milling machines. Norms of accuracy and rigidity - Terminology GOST 17734 88: Cantilever milling machines. Standards of accuracy and rigidity original document: 6. Control cylindrical cantilever mandrel (clauses 1.4.13, 1.4.14, 1.4.15) Basic technical requirements must comply with the specified... ... Dictionary of terms of normative and technical documentation

Lapping - Lapping is a technological procedure for changing the geometry of planes and their surface cleanliness. The essence of the operation is to impart a certain roughness to the mating surfaces. Also used in the manufacture of chemical... ... Wikipedia

Scraping - (also scraping, scraping; from German schaben “scrape”) technology of precision (high-precision) leveling of the surface of a metal product (less often wood or plastic) with a special cutting tool scraper.... ... Wikipedia

Whitworth, Joseph - Joseph Whitworth Sir Joseph Whitworth ... Wikipedia

Assortment, characteristics, dimensions of mounting plates

The use of mounting plates is optimal during the assembly of elements of the structure being erected at the production site.

We produce easy-to-use compact slabs:

- modular type, consisting of several moving elements of a replaceable configuration;

- standard, designed to work with universal structures.

Areas of application of the plate as technological equipment are welding of cars and large-sized equipment, aircraft, test benches, metal cases, control cabinets.

The production algorithm is carried out using mixture casting technologies:

- in sandy-clayey;

- in cold-hardening;

- in liquid glass.

The materials used are gray and high-strength cast iron, steel, and aluminum. The maximum parameters of castings are 8 x 5 x 1 m, accuracy class - 11-13 (GOST R 53464-2009), roughness Rz = 320-1000 microns (GOST 2789-73).

The production cycle for manufacturing mounting plates is carried out using:

- innovative modeling programs ProCast and LVMFlow;

- automatic machines with numerical control;

- furnaces IST 25/ 15/1.5/0, 75, DSP-3M2, designed for the production of castings weighing 0.5 kg - 40 tons;

- equipment for casting slabs 8 x 5 x 1 m;

- thermal furnaces with a capacity of 7 x 7 x 14 m for aging metal;

- modern machines for profile finishing of elements.

“TEST PLATE” in books

PLATE WITH DETONATORS

PLATE WITH DETONATORS All detonators must fire at the same time. Only in this case is the nuclear explosive compressed evenly, and, consequently, a critical mass is formed. This was one of the most difficult problems: how to achieve the “instant X”, a fantastic

Plate

Stove The state of the stove on which food is cooked is connected with your stomach, with what cooks and digests information. The condition of the stomachs of those living in a given apartment can be judged by the condition of the stove. So, if there is burnt food on the stove, this indicates that the information

Kitchen stove

Kitchen Stove• Symbolically, the kitchen stove is associated with the financial situation of the inhabitants of the house. It must be kept clean and work without interruption, which will ensure the arrival of wealth.• The kitchen stove should not be placed in the center of the house.• The location of the stove is in the east or

Plate and ladle

Stove and Ladle Cooking is a magical process of transformation that uses the four elements: Earth (the food itself that grows on the earth), Fire (the source of heat - flame, solar heat, electricity), Water (the liquid used to cook food) and Air

Plate

Slab When you are driving on the highway, well, from Chelyaba to Sverlovsk, after about forty kilometers there will be a bridge like this, where you need to go right. And first, yes, the sign is “Kunashak”. Just don’t go all the way to Kunashak, there will be another turn there, again right, towards the village

Simple Stove

Simple stove A simple stove without oven and hot water box has dimensions: length - 890 mm, width - 510 and height - 770 mm. Its mass is 530 kg. Heat transfer with two fireboxes per day - 700 kcal/h. Materials: ordinary or red brick - 118 pieces, clay - 2.5 buckets, sand - 1.5 buckets,

Stove with oven

Stove with oven Let's add the oven itself to the set of appliances for a simple stove. It is usually installed on the fifth row of masonry so that it is at least 100 mm from the walls. The first row is laid along the drawn figure, making sure that it is rectangular. The masonry is made from

Gas stove

Gas stove Gas stoves first appeared in the USSR in the early 30s, mainly after 1932 in newly built houses, primarily in Moscow, in the very center - in the area of Arbat, Kropotkinskaya and Ostozhenka. They immediately won the love of everyone who had to cook food.

Simple Stove

Simple stove A simple stove without oven and hot water box (Fig. 49) has dimensions: length - 890 mm, width - 510 and height - 770 mm. Rectangular shapes. Weight - 530 kg. Heat transfer with two fireboxes per day is 700 kcal/h. Rice. 49. Simplified kitchen stove: 1 - two layers of felt,

Stove with oven

Stove with oven The stove (Fig. 50) has dimensions: length - 1020 mm, width - 640, height - 770 mm. Weight - 650 kg. Heat transfer with two fireboxes per day is 600 kcal/h. Rice. 50. Kitchen stove with oven: 1 - cleaning; 2 - oven; 3 - firebox; 4 - blower, 5 - felt impregnated with clay

IV.5.2. Gypsum particle board (GSP)

IV.5.2. Gypsum particle board (GSP) This is a modern, high-tech, environmentally friendly and fireproof sheet building material intended for cladding the internal surfaces of premises for various purposes (see insert, Fig. 76). GSP are produced according to specifications

Kitchen and stove

Kitchen and stove However, before you cook, you need to equip the kitchen. Let's start with what we call a stove at home. It should be made of stainless steel and in a gimbal suspension. It doesn't matter how big or stable the boat is. The ability of the slab to swing relative

Using lapping plates

- An abrasive material in the form of a paste or suspension is applied to the installed slab, after which it is evenly distributed over the surface.

- The workpiece is placed on the prepared surface with the side to be processed - it must fit completely on the plane and not go beyond it when processing is performed.

The part is lightly pressed down and, using circular movements, trying not to crawl in one place, the product is moved along the plane.

- After 10–11 movements in a circular direction, the workpiece is removed, and the tool is cleaned of any remaining grinding powder.

- Monitor the condition of the surfaces of parts by visual inspection. In case of visible defects, a layer of abrasive is re-applied and processed.

- The process is repeated until the treated side receives a uniform matte shade or reaches a mirror state.

- After this, it is necessary to check the accuracy of the plane using a calibration tool.

- It is recommended that the final finishing of the product be done not on a cast iron plate, but on a wood grinder using a solution of Vienna lime and alcohol.

The process of working with lapping tools is not associated with great difficulties from a technical point of view

The main thing you need to pay special attention to here is maintaining the angle of the plane. This is especially true for grinding in end planes

Therefore, it is better to combine such products into bags or rub them in using auxiliary bars.