Shops, supermarkets and markets offer a huge selection of smoked fish, meat and poultry. But the attractive appearance of the products does not guarantee a feast of taste. Therefore, many lovers of real smoked delicacies, especially those who own a country house or live in a private house, sooner or later come to the conclusion about their own small smokehouse.

After all, if you take good aromatic firewood, the right piece of meat or your favorite fish, and achieve the right temperature, you can create a truly culinary masterpiece that will delight the owner, his family and guests.

Many people are put off by the price of buying a mini smokehouse, but if you love to cook and want to create something unusual, then you can make a smokehouse yourself with minimal material costs. To do this, you need a little free time, some available materials and relevant drawings.

Features and benefits of the smokehouse

Making a smokehouse with your own hands, right at home, is not difficult, and this process does not require special skills. Definitely it all depends on what kind of smokehouse you want to get as a result.

You can assemble an inexpensive smokehouse of the desired size yourself with minimal time, from almost everything that is lying around the house, has not been used for a long time, but it would be a pity to throw it away.

It is the simplicity of execution and low cost of construction that makes self-assembly of a smokehouse so attractive, especially for people who like to create something with their own hands.

Sawdust container

The sawdust container is the place where the fuel for smoking is placed. It is in it that the wood burns, the heat from which rises to the top and heats the meat. Therefore, the device must be made of non-toxic and durable material.

A cast iron pan or bowl is ideal as a container for sawdust. These are in every summer resident’s home set.

Types and purpose of smokehouse

All types of smokehouses can be classified according to several criteria.

Depending on the manufacturing method and smoking temperature:

Smokehouse for cold smoking

A distinctive feature of such a smokehouse is a fairly long elongated chimney. It is the chimney that ensures 100% combustion of flue gases.

The cold smoked smokehouse model also includes a firebox and the smoking chamber itself. When smoking food in this way, all harmful and toxic substances from combustion products remain on the wall of the chimney, and the food gives off a light smoke, with an aroma from the type of wood that was used for smoking.

The disadvantage of cold smoking is the long cooking process - it can take from 3 to 7 days. However, products prepared in a cold smoked smokehouse can be stored for up to 4 months, which is a definite plus.

Smokehouse for hot smoking

Such a smokehouse has its own engineering features, since hot smoking technology involves the use of special types of wood chips, rather than firewood. Therefore, the combustion chamber is located under the smoking chamber.

The smoking chamber must be airtight so that the products placed in it can be heated evenly.

But the time spent on smoking is comparable to baking in the oven. And the finished product can be obtained in 30-60 minutes. Here everything will depend on the type and weight of the product, since fish requires less cooking time than poultry. However, the shelf life of hot smoked products is only a few days.

Universal smokehouse

In addition to special smokehouses for hot and cold smoking, universal smokehouses can also be distinguished. Such smokehouses are an average option between the two described, and allow you to cook food in two ways.

Thus, when choosing a smokehouse, you should pay attention to the pros and cons of each type: for example, smokehouses for cold smoking are bulky, but the products cooked in them are stored longer and have a brighter taste; while hot smokers are miniature and cooking food takes little time.

Any type of smokehouse is suitable for cooking sausages, various types of meat, poultry, lard, bacon and fish. The taste of the product will differ depending on the chosen smoking method.

By type of mobility, smokehouses can be divided into:

- stationary smokehouses, which are installed in one place and can be used for a fairly large volume of products;

- portable mini-smokehouses, which are a small box that closes tightly with a lid. These smokehouses are designed for hiking and outdoor recreation.

Firewood and wood chips: how to choose the right one

The key to the taste of smoked meats is properly selected firewood . It is known that smoke from different types of wood has completely different flavors. The easiest way is to use purchased wood chips in this case, choosing the one suitable for each type of product:

- alder - universal, suitable for meat, lard, fish and vegetables;

- oak - mainly for smoking game and red meat;

- willow, birch - game with a specific taste, for example, elk or bear, as well as swamp fish;

- cherry, apple tree - cheeses, vegetables, nuts and berries.

The humidity of firewood and wood chips should be within 15%, otherwise too much steam will be generated and the smoked meats will become soggy, after which they will not be stored well.

The costs of making a smokehouse are insignificant; you can use scrap materials and leftovers. A self-made smokehouse and a properly selected smoking mode will allow you to prepare delicacies that are unique in taste and will surprise your family and guests.

What can you build a smokehouse from?

To make a smokehouse, you can use many things that are lying around in the garage, on the balcony and in the barn. This could be an old oven, a refrigerator, or even an ordinary barrel.

Of course, the best option is a stationary universal smokehouse, which can be made of brick. In this option, you can set the required dimensions and properly organize the flow of smoke into the smoking chamber. The heating of such a smokehouse is ensured by a stove-stove, which is connected to a pipe. Such a smokehouse can be an excellent and unusual design solution for decorating a local area, veranda or guest gazebo.

For simpler or temporary smokehouse designs, a metal box or wooden barrel with a volume of up to 100 liters is quite suitable.

Portable smokehouses can be built from any household items: pans, buckets, fire extinguishers. An old refrigerator or gas stove may also be good options.

The main thing is to choose an item that can accommodate a couple of meat grates and provide space for sawdust or firewood under these grates.

When making a smokehouse from metal objects, it is important to use stainless elements, since they do not oxidize under the influence of high temperatures and moisture, are not destroyed by smoke and are easy to clean.

“Stainless steel” becomes brittle after prolonged use, so elements made from it will have to be replaced from time to time.

What is smoking in an electrostatic field

Smoking products in an electrostatic smokehouse occurs faster, the smoke is distributed evenly. Cooking smoked meats is a rather lengthy process.

Represents the slow penetration of smoke and some combustion products into the product. In this case, a number of specific and biochemical reactions occur that lead to the denaturation of proteins. Fish, meat, and sausage acquire a specific pleasant taste. Smoking in an electrostatic field differs only in the timing. Acceleration is provided by the following:

- the smoke is produced by the generator, not the coals;

- it passes through the grid to which the anode is connected, the current strength is small;

- the smoke is ionized and enters the smoking chamber;

- the products in the chamber are connected to the cathode;

- since ionized gas and fish and meat have opposite charges, the product literally attracts smoke;

- ionized smoke particles are very evenly distributed throughout the meat.

There are two types of smoking:

- hot – the process lasts 2–4 hours at a temperature of +120°C;

- cold – requires from 10 hours to 2 days and is carried out at +215°C.

Cold smoking is preferable; such meat is stored much longer.

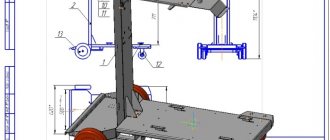

How to Prepare Smokehouse Drawings

You don't need to be an engineer to assemble a smokehouse yourself. To understand the assembly mechanism, you just need to decide on the material for manufacturing, the type of smokehouse and select the appropriate drawing.

However, even the finished drawing will have to be slightly adjusted to the size of your smoking chamber.

If we are talking about a stationary brick smokehouse, then you will have to work on the drawings yourself, or turn to professionals to develop an individual project.

Manufacturing

Stores sell machines for smoking meat, but if you don't want to spend money, we'll give you tips so you know how to make a smoker at home.

Making such a design will be an interesting and exciting activity, because there are many options and methods. The device is made from various materials. We suggest considering the simplest options.

From a barrel or bucket

Make a smokehouse from an iron barrel: this solution is the most affordable. To begin, cut off the bottom of the container and attach a grid (or reinforcing bars) to it at 2 levels.

Place a tray below. At the very top, food is hung on hooks. To make a smokehouse, a metal bucket is suitable. Insert 2 stainless steel grates inside.

One of them is placed at a distance of 10 cm above the bottom, and the other 5 cm above from the other mesh. Place up to 2 cm of wood chips on the bottom of the bucket. Place the bird or fish on the grill. Now cover the mini-smoker with a lid and put it on fire.

You can fumigate food in a bucket: it will be ready in 15 minutes. after the smoke appears. Remove the bucket from the open fire and wait until it cools down.

This design works without electricity, so it is well suited for outdoor trips or evening picnics in the country. At the same time, you can save energy.

The bucket won't take up much space. However, a smoker installed on a fire can be dangerous if not used correctly.

If you use it incorrectly, you may get burned or injured. Do not touch the bucket or barrel while the fire is burning as the metal will become hot quickly.

From an old refrigerator

Often people take old household appliances to their country house. Refrigerators are placed in sheds or utility pantries and various small items are stored in them. However, they make practical smoking units.

Masters give advice on how to make a smokehouse with your own hands from a refrigerator. Take out everything inside and leave the base itself with the door. Make a hole at the top where the smoke will escape.

Attach 9 corners to the walls on the inside of the refrigerator (two on each level).

At 2 levels in the upper part, fasten the grilles, hang hooks and strips. Secure the corners at the bottom to secure the drip pan. Sawdust is placed in another tray.

The hot-smoked smokehouse will be made by yourself and ready to use when you install the electric stove. The stove is installed in the lower part of the refrigerating chamber, and a container with shavings is placed on it. Close the door tightly to prevent air from entering the middle.

Stainless steel

To make a reliable smoking chamber, choose a durable metal - stainless steel. In appearance, this design looks like a box. In the inner part, corners for two metal gratings are welded.

Tourists can take this type of smokehouse on a hike. For fumigation, take small logs of deciduous trees or shavings.

Place pieces of lard or game on the mesh, then close the box and secure it over the fire. The first portion will be ready in 20 minutes.

Made of brick

Such a stationary smokehouse is installed on personal plots. Find a place for a guest area in your garden and prepare a site for its installation.

You determine the camera parameters yourself. As with everything else, choose the wood to fumigate. To burn wood in a stationary structure, a stove-stove is installed; it is installed outside, and not in the chamber itself.

Then install a pipe between the stove and the smokehouse. When you carry out construction work, follow the instructions and ask the master for advice.

Take out your work gloves, check whether the tools are in good working order and the condition of the materials. Be careful when using the smokehouse, follow the recommendations.

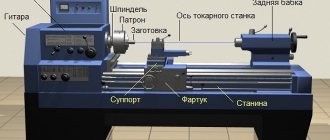

What does the smokehouse consist of?

Any smokehouse, regardless of what it is made of, has the required elements:

- the smoking chamber is the basis of the smokehouse, which must close tightly and be practically airtight so that the smoke remains in the chamber and it can warm up to the required temperatures;

- lattice. This is the part on which the products are laid out and which is placed in the smoking chamber. You can install one grill or several, it all depends on the number of products. It is possible to use a ready-made grill from an old oven, a barbecue grill, or make it yourself, for example, from thin fittings or thick wire. Hooks can also perform the function of a lattice - you can hang meat or fish on them;

- tray for sawdust and shavings;

- ash collection box;

- a tray for collecting juices and fat that drain from products during the smoking process;

- smoke generator. In hot smoking chambers, this function is performed by sawdust, which smolders at the bottom of the chamber, which provides thick smoke inside. But in cold smoking chambers, a more complex system should be installed in the form of an electrical element for heating, a temperature sensor, and a thermostat. This is due to the fact that to prepare cold smoked products, the smoke temperature should not be higher than 35 degrees C;

- fan/compressor. A useful, but not necessary element for a smokehouse. With its help in hot smokehouses, you can increase the circulation of smoke, which will raise the smoking temperature and, accordingly, speed up the cooking process;

- lid with water seal. To ensure better sealing of the chamber, you can create a recess around its perimeter and fill it with water. Due to this, smoke will not leave the chamber;

- heating source. Depending on the size of the chamber, the heating source can be a stationary or temporary grill, an electric stove or a gas burner.

How to use it correctly

Before placing certain foods in the smoker, they must be carefully prepared. For example, fish is cleaned and soaked in brine. For 4 kg of fish you need to take about a glass of salt. Some types of fish need to be generously rubbed with salt, wrapped in cling film and, pressed with a lid, left for two days. Then the fish is dried for a couple of hours and completely cooled. Only after this can you begin the smoking process.

What can you cook in an electric smoker?

With an electric smoker you can cook a wide variety of smoked meats.

Most often, meat and fish, cheese, homemade sausages, vegetables and even some fruits are prepared.

The finished product is not only very tasty and aromatic. It does not contain any harmful components or additives that can adversely affect human health.

Useful tips

In order for the use of an electric smoker to be completely safe, and the prepared products to be truly tasty, you should adhere to some simple rules.

- It is necessary to ensure that the food does not touch the walls or heating element during smoking.

- Absolutely all elements that can become electrified must be carefully isolated from the device body.

- During cooking, do not touch food with your hands.

- Humidity indoors or outdoors should not be more than 80%.

Cooking in an electric smokehouse is very simple, regardless of whether the model is factory-made or self-assembled.

Smokehouse Assembly Instructions

Understanding the process of smoking products, it is absolutely not difficult to assemble a smokehouse yourself, come up with its diagram and even develop instructions. Since there are a huge number of items from which you can make a smokehouse with your own hands, there are ready-made instructions for transforming them into home smokehouses.

The simplest design of a smokehouse made of polyethylene film

The smokehouse made of polyethylene film is intended for cold smoking.

To create it you will need:

- about 2 meters of thick polyethylene film, the kind that is used for greenhouses or covering plants;

- two-meter wooden stakes;

- wooden or wire rods;

- for work you need a hammer, an awl or a gypsy needle, thick threads, fishing line or thin wire;

- and the main thing is to allocate a space of about 1 square meter for installing the structure.

The stakes, which serve as the frame of the smokehouse, are driven into the ground, and for stability they are fixed together with crossbars made of rods or wire. Additionally, the structure should be secured diagonally in several rows.

The products that will be smoked are hung on the partition rods at a distance from each other so that they do not touch.

The polyethylene film must be sewn according to the principle of a bag, which is pulled over the frame with hung products. In this case, the bag should not touch the ground, since there should be space between it and the ground.

This space is left for pouring hot coals. A layer of grass is laid on top of the coals, the smoldering of which will create smoke for smoking. Afterwards, the bag is pulled to the ground. To ensure better tightness, the edges of the bag should be secured around the perimeter with stones or any heavy objects at hand.

If the choice of products for smoking is fish, chicken or sausages, then cooking will take about 3 hours. If you plan to smoke denser types of meat, then the smoking procedure must be repeated.

Bucket smokehouse

For such a smokehouse, any old, unnecessary bucket with a lid and a couple of stainless steel grates of different sizes will do.

The bottom of the bucket is filled with sawdust or shavings. Then, a smaller grid is fixed at a height of 10 cm from the bottom, and a second one is placed above it (you can get by with one grid if there is not a lot of food).

The products are placed on the grates, and the smokehouse is placed on the fire, covered with a lid, so that the smoke remains inside the smokehouse bucket.

Smokehouse from a barrel

The homemade barrel smoker is the most popular. It can be made from either wooden or metal barrels. The structure of a barrel smokehouse is similar to a bucket smokehouse. However, the size of the barrel allows you to also use hooks for smoking.

As the basis of a smokehouse, a barrel is also convenient because it allows you to make different types of smokehouses from it:

- a smokehouse made from a barrel for hot smoking, assumes that the heat source will be located under the barrel itself;

- a barrel smokehouse for cold smoking will consist of a free-standing barrel and a 2-meter chimney that will connect it to a heat source;

- universal, multifunctional barrel smoker. For this option, you will need two identical barrels with a volume of about 200 liters. The barrels are fastened together in the shape of the letter “T”, and if they are made of metal, then the best option would be to weld them into a single whole. The upper barrel serves as a smoking chamber, into which a grate, hooks and a tray for collecting fat are installed. A firebox is installed in the lower barrel, in which you need to place a tray for sawdust. And the source of heat is the fire under the barrel. On the convenient side of the lower barrel, it is necessary to cut an opening to install the door and valve, to control the fire and regulate the flame. This design can be used not only for smoking, but also as an oven for baking, heating food, barbecuing and even grilling.

Smokehouse from an old refrigerator

A very good option for a home smokehouse is an old refrigerator. This non-working device should not be thrown away or sold for scrap. It is enough to clean it of the electrical filling and the refrigerator chamber can easily be transformed into a chamber for a smokehouse.

To do this, inside the refrigerator, using corners, grates and hooks for smoking, a tray for collecting fat, and at the very bottom a tray for sawdust are installed. A small hole is made in the ceiling of the refrigerator to install a chimney. And since the chamber of an old refrigerator is used, it is worth paying attention to how tightly the door is closed to ensure the tightness of the smoking.

Metal smokehouse

A more convenient and practical smokehouse model can be made from metal. However, this will require certain skills and a specific set of tools: namely a welding machine and a grinder with a metal disc.

The simplest and most functional form of such a smokehouse is a square or rectangle, that is, it is necessary to create a box into which all the elements of the smokehouse are built.

Metal - stainless steel (the best option for operation, but difficult to weld) or cold-rolled steel (a material that is very light and flexible in work, but is susceptible to oxidation and is short-lived).

The dimensions of the smokehouse depend solely on personal wishes.

Having decided on the shape, size and material, the metal sheets are cut with a grinder according to the selected parameters. Using a carpenter's angle, the sheets are welded together at an angle of 90 degrees to form a box. The joints of the structure must be welded both from the outside and from the inside, for better tightness of the smokehouse.

After creating the body, the bottom of the smokehouse is cut out and welded to it, also with double-sided seams.

To make the lid, cut a sheet to the size of the smokehouse box and 4 narrow strips for the sides of the lid. All elements are welded together using double-sided seams.

To make it easier to carry the smokehouse, handles can be welded on the sides.

The inside of the smokehouse is equipped with fasteners for installing grates, hooks and a tray for collecting fat.

This smokehouse can be heated either over an open fire or on an electric stove.

Smokehouse from a gas cylinder or fire extinguisher

An unnecessary gas cylinder can also be used as a home smokehouse. However, in addition to certain skills in working with an angle grinder and a welding machine, you will also have to take into account safety rules.

Before starting work on the manufacture of a smokehouse, you will have to carry out preparatory work and “neutralize” the gas cylinder. To do this, you need to open the valve and give time for the remaining gas from the cylinder to completely come out. After this, the valve is sawed off. Everything that remains in the cylinder is poured into a separate container, the cylinder is thoroughly washed and dried.

A door is cut out of part of the same cylinder (for loading products inside), which is placed on hinges and again attached to the cylinder.

To equip the firebox, the bottom of the cylinder is sawed off, and a firebox is welded from separate sheets of metal, which is welded to the cylinder.

At the end of the work, to ensure the safety of food preparation, the structure must be well calcined.

Next, you can install gratings, hooks and trays inside the cylinder chamber.

Smokehouse made of brick and stone

In this part we will talk about a universal stationary smokehouse for hot and cold smoking, which also serves as a barbecue, grill, barbecue, Russian oven and oven.

A brick smokehouse is not only an ideal device for cooking, but also a very colorful decorative element for a personal plot.

The design of such a smokehouse is quite complex, so to build it you should contact designers or look for ready-made options on the Internet. In both cases, when creating such a structure, you should strictly adhere to the construction plan, drawings and instructions, since failure to comply with them will lead to the complete unsuitability of the smokehouse, and accordingly, loss of time and finances.

First of all, a decision is made on the location of the smokehouse: whether it will be a separate structure, part of a veranda or gazebo.

The basis of any capital structure is its foundation, a brick smokehouse is no exception, and if you start laying on open ground, then under the weight of stones and bricks the ground will sag, which will lead to the destruction of the structure. Therefore, the foundation should be strengthened with reinforced concrete or reinforcing mesh, and some time should be given for the foundation to gain strength.

On top of the foundation, brick or stone masonry of the wall of the lower belt is made, taking into account a tunnel chimney with a length of plus or minus 2 linear meters. In order for the smokehouse to be universal (cold and hot smoking), the chimney pipe should be insulated with any mineral insulating material.

Before laying the wall of the second belt, the first one is filled with a thin concrete screed and reinforced. A ready-made concrete slab is also suitable for separating wall belts.

The design of a brick smokehouse involves the presence of two chambers: one of which is the smoking chamber itself, and the second is a stove, which can be used independently for preparing various dishes and is a heat source for the smokehouse. The furnace chamber should be built exclusively from refractory bricks.

Closer to the chimney, a chamber for the smokehouse is laid out. There is no open fire or too high temperatures, so any type of brick will do and no interior finishing is required. To ensure tightness, a tightly closing door must be installed on this chamber. For a brick stationary smokehouse, most often they make not a metal door, but a wooden door from fruit trees (apricot, cherry, apple tree). Such a door will give a rich aroma to the products when smoked.

A chimney pipe is installed on the smoking chamber. With its help, you can regulate the smoke draft for the intensity of sawdust smoldering and, accordingly, select the type of smoking:

- for hot smoking, sawdust combustion increases and smoke draft decreases;

- for cold smoking, the fire decreases and the draft increases, due to which the smoke is cooled to a temperature of 35 degrees.

The brick smokehouse chamber is also equipped with grates, hooks and trays. Another advantage of this smokehouse is that it can be used as a storage chamber for kitchen and yard supplies.

What are the advantages of gas stoves

The stoves have an oven that can be powered by electricity or gas. But they are not eternal. Over time, they stop functioning normally.

They are disposed of, sold for scrap, or simply taken to the countryside until a final decision is made.

But such a device can become an excellent basis for assembling a full-fledged smokehouse. A number of stove elements are already ready to provide smoking, and there is no need to redo them. The improvements are minor. This is much easier than making a smoking unit from scratch, or using an old refrigerator as a base.

The main advantages of gas stoves include the presence of the following structural elements:

- Grooves on the side surfaces inside, or telescopic guides. Grates are installed on them, and hooks with food are hung. This simplifies the process of loading and unloading raw materials.

- Wire racks and baking trays. If they have not had time to rust, then after simple cleaning you get an excellent basis for laying out products for smoking. Trays are commonly used as surfaces to collect fat and juice.

- Thermal insulation materials. If you've ever had to disassemble a gas stove, you've probably seen panels and slabs inside, as well as facing materials with thermal insulation properties. They allow you to maintain and maintain the temperature inside the stove, and this is very important for smoking.

- Seals. They create the required degree of tightness.

Another comparison with the same refrigerators. The construction of gas stoves uses materials that are designed to withstand high temperature loads. Therefore, if you follow the smoking rules, the plate will not be deformed and the metal will not crack.

Manufacturers have also provided special coatings that make it easy to clean the stove from dirt. This simplifies the issue of caring for a homemade smokehouse based on a household appliance.

There are no significant shortcomings here as such. Therefore, old gas stoves have become a popular solution for making smokers.

Smokehouse chimney

The chimney is the most important part of the smokehouse, the arrangement of which deserves special attention.

When making a stationary smokehouse, the chimney can be laid in the ground. This design will be especially relevant for a cold smoked smokehouse, since with this arrangement of the chimney the smoke cools faster; hazardous combustion products settle in the ground and are processed by bacteria; and condensation is absorbed into the ground.

To equip a smokehouse with such a chimney, you need to find a place with a slight hillock. Depending on the landscape of the site, it can be natural, or it can be created artificially, specifically for the smokehouse chimney. The slope is necessary for good smoke draft.

On the hill itself, a shallow trench is dug along the length and width of the chimney, into which a pipe is installed or ordinary sheets of metal are simply placed on top. To ensure good thermal insulation, the chimney is covered with a dense layer of earth.

The heat source of the smokehouse - the firebox - is placed at the bottom of the slope, and the smoking chamber itself is at its top, and they are connected to each other by a chimney.

The best material for a chimney is metal. However, such a chimney requires constant maintenance, since soot settles on its walls, which needs to be removed.

It is not advisable to make a chimney made of porous materials, such as brick, without additional finishing. Such a chimney will absorb moisture and smoke along with dangerous carcinogens, which in the future will negatively affect the quality and taste of smoked products.

Components of the structure

For hot smoking

The design is in the form of a container with a tight-fitting lid. It is made from almost any metal barrel tanks.

The hot smoked smokehouse consists of:

Fireboxes. It is placed under the chamber and plays the role of a heating element; Hermetic compartment (smokehouse). This element ensures good heating of products and maintaining the specified temperature; Water seal. It is recommended to install it, since the shutter helps reduce the level of carcinogenic components in smoke and regulates air flow; Grilles. For displaying products; Removable tray; collector for melted fat released during cooking.

For cold smoking

These modifications are constructed according to the basic law - the smoke must cool down before reaching the products. These models have any standard sizes and consist of the following parts:

Firebox

It can be made from galvanized sheets or ordinary bricks (when installing a firebox, it is additionally equipped with an ash pan and a door to regulate the smoke flow;

Smokehouse compartment

Considering the low temperature of cold cooking, it can also be built from wood;

Chimney

Combining the chamber and the firebox, metal will be a suitable raw material for its manufacture, but it is advisable not to use brick with its porous texture.

Sources

- https://gidpopechkam.ru/pechki/koptilnya-chertezhi-razmery.html

- https://pro-kopchenie.ru/koptilni/koptilnya-goryachego-kopcheniya.html

- https://tytpodelki.ru/kak-sdelat-koptilnyu-goryachego-kopcheniya/

- https://o-remonte.com/koptilnya-svoimi-rukami-kholodnaya-gor/

- https://DimDom.ru/koptilnya-goryachego-kopcheniya-svoimi-rukami.html

- https://jamaster.ru/kak-sdelat-koptilnyu-goryachego-kopcheniya-svoimi-rukami/

- https://homius.ru/koptilnyu-goryachego-kopcheniya-svoimi-rukami.html

- https://HouseChief.ru/koptilnja-gorjachego-kopchenija-svoimi-rukami.html

- https://moekopchenie.ru/koptilni/svoimi-rukami/goryachego-kopcheniya

- https://landshaftdizajn.ru/koptilnya-svoimi-rukami/

- https://stroy-podskazka.ru/koptilnya/svoimi-rukami/

- https://grillrest.com/koptilni/svoimi-rukami-instrukciya/

Where is the best place to place a smokehouse?

This article examined options for stationary and mobile home smokehouses. However, choosing a place to install any smokehouse is extremely important, since the smoking process takes time and is associated with the release of a large volume of smoke. Therefore, using the smokehouse indoors is not possible.

Harmful substances from combustion products can also harm vegetation and outdoor pets.

Thus, when choosing a place for a smokehouse, it is worth considering many factors and choosing it taking into account the safety of people and nature, as well as the characteristics of a personal plot or recreation area.

As for the storage of portable (mobile) smokehouses, after use they can be hidden in a garden house, garage or basement; and finished smoked products are stored for a long time in any cold and dry place.

Material selection

It is extremely important to choose the right material from which our smokehouse will be made. Usually there are two ways to go here

Using brickwork, a grill, a barbecue and, accordingly, a smokehouse are combined, or the latter is welded from a metal sheet. So, brickwork has several significant disadvantages. Firstly, it takes up a lot of space, and secondly, over time it develops an extremely unpleasant smell, which is why you definitely don’t want to cook anything there. Yes, and it's expensive.

A normal homemade hot-smoked smokehouse can be obtained if you use a 4-mm metal sheet. This thickness is considered optimal. If you take less, the metal will burn out quickly enough, therefore, our smokehouse will turn out to be short-lived. If you take more, you will not be able to achieve a high heating rate. Although smoking fish in a home smokehouse can be done on a metal sheet of less thickness, since the fish cooks very quickly.

Option #1. Cold smoked design

This type of smokehouse is made from a wide variety of materials. Below is a step-by-step guide to creating a simple design using plastic film.

Step one.

First you need to purchase the plastic film itself. Two meters of thick film (the kind used for greenhouses) will be more than enough. From one end, the sleeve of the purchased film is sewn up in such a way that the result is a kind of bag.

Step two.

Next, you need a place where the mini-smokehouse will be located. To do this, you will need a small leveled area of 1 square meter. A two-meter stake should be driven into each corner of this site. At the top, the stakes must be connected to each other using crossbars. It is important that the structure is sufficiently stable.

Step three.

Opposite stakes must be connected using diagonal slats in approximately two to three rows.

Step four.

Fish, already prepared for smoking, should be hung on these slats. It is also important that the bodies of the fish do not touch each other.

Step five.

The prepared plastic “bag” must be pulled over this structure to approximately half its height. After this, the site should be filled with 1/2 a bucket of hot coals, on top of which green grass should be laid.

Design with smoke generator

A smokehouse with a smoke generator has a more complex structure. In addition, not all stages of its manufacture can be completed with your own hands. Some parts will have to be purchased or ordered to be manufactured.

The work is performed in the following order:

- First you need to drill a hole with a diameter of 27-28 mm in the lower part of one of the side surfaces of the gas stove. It will be used to supply smoke.

- Then a standard ¾” water pipe is inserted into it with a section with a longer thread length and secured with two low nuts. Even with the large thickness of the double side partition, this should be enough for reliable fixation.

- The same operations are carried out on the opposite sidewall, only this time the hole should be located on its upper part. This unit will perform the functions of removing excess smoke and relieving excess pressure in the chamber. A ball or plug valve is screwed onto the second end of the outlet pipe, which will perform adjustment functions.

- To control the temperature, a thermometer calibrated to 170-200 °C is mounted in the oven.

Now the smokehouse is ready and you can start making a smoke generator. The ejector-type device combines high efficiency and ease of manufacture. To make such a generator with your own hands, you will need the following materials:

- Pipe ¾";

- Tube with an internal diameter of 6-7 mm;

- Pipe with a diameter of 90-130 mm and a length of 50-70 cm;

- Neck with ¾" union nut;

- Union;

- M6-M10 screw with wing nut;

- Metal sheet 3-5 mm thick.

- Air compressor;

- Connecting hose.

Most of these materials can be easily found in any garage or shed of a private home. An aquarium aerator with a capacity of up to 60 l/hour is quite suitable as a compressor.

First, you need to cut a circle from a sheet along the inner diameter of the larger pipe, drill 20-25 small holes in it and weld it inside at a distance of 2-3 cm from the edge. This kind of sieve will serve as a fire pit. Then a screw is welded to the inner wall of the pipe and a round lid is put on it, which will serve as an ash pan. A hole (10-12 mm) is drilled a little above the fire pit for igniting wood chips.

Smokehouse with fuel poured into the chamber

There are two fundamentally different designs, differing in the principle of laying wood chips or another source of smoke. The simplest is considered to be a smokehouse with filling at the bottom of the cabinet, since it requires performing a minimum number of operations with your own hands.

Work order:

- Remove the drying cabinet door and its back wall;

- Remove the gas burner from the oven;

- Install an electric stove (1.5-2 kW) or build a fire pit under the bottom of the oven or inside the drying chamber;

- Drill two to four holes with a diameter of 10-20 mm in the lower part of the side walls for air flow and one to two in the upper part to remove exhaust smoke. To do this, you will have to use a drill with a regular cylindrical or step metal drill.

This camera has a number of significant disadvantages that limit its use:

- Impossibility of cold smoking;

- Difficulty in adjusting smoke distribution: the number and diameter of holes will have to be selected by trial and error;

- High heating inertia (impossibility of quickly reducing temperature) can cause too intense smoldering of wood chips or ignition of fat, which will lead to food spoilage;

Smoking products

There are two types of smoking products:

- cold;

- hot.

Cold smoking

If the product is processed using “fumigation” with chilled smoke and is not subjected to heat treatment, then this process is referred to as cold smoking. Smoke treatment is carried out for several days, and its temperature is 20-25 degrees.

Cold smoked products are stored for a long time, but due to the length of the technological process, this method is used less frequently

than hot smoking.

Hot smoking

The smoke used in the hot method of processing food reaches a temperature of 45 to 120 degrees, and after just a few hours you can eat a delicious dish.

- Hot smoking technology for preparing meat or fish is similar to the processes that occur when frying, boiling or baking foods.

- Hot smoking is quite feasible at home, on a hike or in the country.

Types of smokehouses for hot smoking

Currently, you can find suitable options for household, camping or professional smokehouses on the market. It can be:

- home smokehouse;

- household smokehouse;

- camping smokehouses of various modifications.

In order to choose the right home smokehouse, you need to know what requirements it must meet:

- A smokehouse used in residential premises should not smoke. You can only purchase a home version, which is based on external heating, but does not emit smoke. In this case, the wood chips smolder without access to air. The container where the homemade product is directly smoked must be sealed with a water seal.

- When smoking, it is recommended to use dry wood chips. Smoking with soaked wood chips does not give the expected result.

- The ideal smokehouse is one in which the wood chips are isolated from the product itself. This requirement is a consequence of the technology of the smoking process, in which fat and juice formed as a result of heat treatment can end up on the wood chips. In this case, the smoke is saturated not with the aroma of wood, but with the aroma from the components of fat combustion.

Thus, the home version of the hot smoking device has the necessary portability and functionality, as well as an autonomous operating principle.

Smokehouse for gas oven

Today on the market there are a number of high-quality models of smokehouses that use a gas appliance such as a stove. For all presented models, smoking occurs without external intervention. Here the chimney is the hood, and the fireplace is the stove.

The smokehouse installed on a gas appliance has the following technical data:

- material: high-strength stainless steel. Different models have different dimensions and differ in wall thickness;

- high tightness;

- complete with lid, grates, grease trays, briquettes (with a bag for carrying them). Devices equipped with a water seal are popular.

The consumer needs to know that the device, designed with a water seal, for normal operation will require a hose to be routed into the ventilation hole (possibly through a window).

To smoke food, the smokehouse is installed on a gas stove. Then water is poured into the water seal. After this, the products are stored for smoking. The presence of a water seal prevents smoke or odor from entering the room, which is an advantage of the device.

A smokehouse for a gas stove will start smoking only after the burning gas burner heats the bottom and the wood chips begin to slowly smolder. The required temperature in the device casing is set by regulating the gas supply. The stove must be turned on until the work is completed.

The smart smokehouse performs the entire home smoking process independently, without your intervention. In addition, it ensures environmental friendliness and savings in the consumption of the consumed power source.

DIY home smokehouse

You can implement a very simple home smokehouse project yourself using a gas stove and range hood.

Sequencing:

- tie smoking products to the base of the hood;

- place a dish (drip tray) below for draining fat;

- use a jar, for example, of tomato paste, as a container for wood chips. You need to place a bunch of wood chips at the bottom and light the burner of the lowest power;

- turn on the hood and gradually increase the heat. When the wood chips begin to smoke, gradually reduce the flame.

Hot smoking of a product with this method occurs due to the fact that the distance that the smoke travels to the raw product is sufficient to cool it to the required temperature.

With the right technology, smoking eliminates ignition from heating wood chips, and pieces of wood of the same size make it possible to obtain products that are evenly smoked on all sides. More complete information on the topic of a homemade smokehouse made by yourself and photos of its step-by-step execution can be found on the Internet if desired.

Preparation of materials and tools

To make a smokehouse you will need:

- materials for making the camera

. This could be wooden boards, plywood, an old gas stove, etc.; - strong reinforcement

, the diameter of which must be

at least 6 mm

;

steel wire- materials for creating a chimney

the pipe

itself ; - grinder

with a disc for cutting metal; - welding machine

; - nails and hammer

; - yardstick

. _