Angle grinder (grinder) METABO WE 15-150 Quick. Photo 220Volt

High-quality work and maintaining health in the vast majority of cases when working with an angle grinder depends on understanding its structure and correct working methods . An angle grinder, commonly known as an angle grinder, is a tool that does not tolerate neglect of safety rules . This article will cover in detail all the nuances and techniques of working with an angle grinder, as well as safety standards that require strict compliance.

Why do you need an angle grinder, how to use it, instructions for dummies

The grinder or angle grinder got its name because of the country where its production was established. The first machines were exported to the USSR from Bulgaria ; at that time they were not multifunctional and only allowed for grinding various surfaces. Later , the device of the grinders was modernized and allowed multifunctional use, which will be discussed below.

The Makita GA 6021 C angle grinder is suitable for cutting tiles. Photo VseInstruments.ru

The external structure of the grinder is related to its purpose: an elongated body in which the gearbox and electric motor are located, the body itself has a molding for the handle, a side handle and the grinding disc itself are fixed on the working part, which is covered with a protective case. The versatility of angle grinders is ensured by changing disk attachments , which are selected depending on the type of work and working surface. Discs and attachments are attached to a special seat and screwed with a spindle or a clamping washer.

The main tasks of an angle grinder include : grinding and polishing rough surfaces, cutting ceramics and stone, glass, concrete monolith, wood, etc. - it all depends on the choice of attachment.

Cutting, metal work and more

Cutting metal with a grinder is quite a common procedure. For this purpose, special cutting discs are used : solid, that is, representing a thin circle with one hole for mounting on the spindle, or perforated, which have oblong slots from the edge of the disc to the center. Perforation is necessary for self-cooling of the disk with air.

To master the techniques of working with an angle grinder, you need to familiarize yourself in detail with its structure. Structurally, the tool consists of a mounting head - a spindle on which equipment is placed - wheels for grinding or cutting, an elongated or rectangular body, one or two handles. The equipment depends on the requirements for the types of work using an angle grinder:

- Cutting of all kinds of materials, including high-strength composite alloys.

- Grinding and cleaning of surfaces.

Important! Under no circumstances should you work with an angle grinder if the equipment is not secured to the spindle using a pressure flange and nut. A wrench is used for this.

How to nag from yourself or towards yourself

If the grinder is part of a machine for cutting ceramic, wooden or stone slabs, then cutting towards itself is allowed , subject to two rules:

- The operator's body is located to the side of the cutting line.

- The machine is equipped with additional protective guards that limit the movement of the angle grinder beyond the working area.

If the angle grinder is in the user’s hands and is held only by hand force, then cutting towards oneself is strictly prohibited. All movements on the surface are made strictly from yourself.

Important! The circle on the angle grinder rotates clockwise, if you make movements away from you, then the rotation of the circle and the independent movement of the grinder can combine, an amplifying resonance will arise, and the grinder can “fly out” of your hands. Therefore, it is necessary to hold the instrument firmly in your hands.

Grinding

The classic grinding procedure is carried out as follows: if it is not possible to connect a vacuum cleaner to the casing, then the work must be carried out outdoors . If the work is carried out indoors, then it is better to use some kind of backing material as dust collectors, for example old newspapers. The blade guard must protect the operator and not obstruct vision.

Angle grinder AEG 451410 WS13-125XE in operation. Photo 220Volt

When working, you should adhere to the following methodology:

- The circle is held to the surface at an angle of 3-5 degrees, light back-and-forth movements are performed. If you put pressure on the disc, dents and dents may form on the wood.

- For some types of wood, it is advisable to use discs with different roughness - coarse at the beginning and finely abrasive upon completion of the work.

- If the surface of the wood needs to be varnished, then after the grinder it is better to use a belt or rotary sander.

Polishing

In order to create a polished surface, an angle grinder is first used, then a belt sander, and then liquid varnishes and polishes.

The work is carried out as follows:

- The grinding wheel is used to initially clean the surface. The disk is held in almost complete contact with the surface, the disk operates without pressure from the user.

- Thin sheets of wood or metal are secured with a clamp and placed against the stop.

- Using an angle grinder you can create a perfectly smooth, mirror-like surface of soft wood and metals. But for rocks and varieties that are characterized by increased hardness, additional types of processing will be required.

Stripping

In order to effectively remove varnish or polishing residues, it is necessary to use disc-shaped discs, the surface of which is lined with sandpaper of different roughness.

- The circle is held at an angle of up to 30 degrees and fed in a reciprocating motion without pressure.

- Thin sheets of wood or metal are secured with a clamp and placed against the stop.

- Using an angle grinder, you can only remove the base of the old coating, after which you will still need to be treated with belt sanding.

Cleaning metal with a grinder

The subtleties of working with a grinder on wood

Various attachments are used for grinding surfaces. Most often, a circle is used, on which a round sheet of sandpaper is attached with Velcro. A petal disk with sandpaper petals attached to it is also used. It is more convenient, but the version with Velcro is reusable (if handled skillfully), which is much more profitable for large production volumes (a sheet of sandpaper costs an order of magnitude cheaper than a petal attachment). Brush and grinding discs are used for grinding painted and rusty surfaces, and sharpening discs are used for sharpening the cutting edges of tools.

Angle grinder Makita GA5030

An angle grinder is great for rough processing of wooden surfaces. The round nozzle polishes the surface very quickly - several times faster than a conventional sander. This occurs due to the high spindle speed (10,000-12,000 rpm). But high rotation speed also has disadvantages. This is, first of all, a large amount of noise and dust during operation of the device. Therefore, take care of a good dust extraction. When working indoors, it is highly advisable to connect a construction vacuum cleaner to the UGM. And if conditions allow, it is better to sand wooden surfaces outside.

Another disadvantage of angle grinders is the inability to properly regulate the rotation speed (this function is available in vibratory grinders, but is usually absent from angle grinders). Only angle grinders with the option of adjusting the number of revolutions are suitable for polishing; various polishing discs cannot be used on high-speed angle grinders.

In general, it is much more difficult to perform delicate work with an angle grinder at high speeds. Especially when processing a cross-section of wood fibers, you can easily overdo it and burn the wood (and at the same time ruin the circle of sandpaper). Do not press the tool tightly against the wood, do not keep it in one place for a long time, so as not to cause scorching due to overheating. And try to hold the tool tightly when working. The rotating circle with sandpaper (or flap disk) must be kept strictly parallel to the plane being processed. Misalignment can lead to damage to consumables and the surface being treated.

For large-scale activities, allow the instrument to rest and cool down. Especially if it is a household tool. Such models are not designed for continuous operation 24/7, usually for a maximum of 8-10 minutes of continuous operation.

DeWALT angle grinder

Safety precautions

Before work begins, the grinder needs to be prepared : select an attachment and secure it to the spindle. If you are choosing a disk, then you should take into account an important rule: the smaller the diameter of the disk, the higher the rotation speed it can withstand. Therefore, it is necessary to familiarize yourself with the power parameters of the angle grinder . If the disc is selected incorrectly, it may break during operation, and this will also lead to wear on the grinder’s mechanisms.

Important! It is strictly forbidden to mount discs larger than the permissible diameter on the grinder.

Discs with traces of deformation, wear or cracks are immediately rejected and removed from the grinder; their use is prohibited. After securing the disk to the spindle, you need to check that it rotates correctly during idle start . To do this, you need to turn on the grinder and rotate it at full power for 1-2 minutes. It is considered that the grinder is ready for work if, during idle rotation, there is no contact with the body by the disk, vibration or extraneous noise.

Safety goggles with direct ventilation ROSOMZ ZP2 PANORAMA super PC 30130. Photo VseInstruments.ru

It is very important to fill in a number of strict prohibitions:

- You cannot work with a bracelet on your hand or any other jewelry - they can get wrapped around the attachment during operation.

- You must not start work while feeling unwell or intoxicated.

- It is prohibited to mount circular disks for cutting wood on a grinder.

- You cannot drive the grinder along the surface towards you.

- Do not let go of the grinder until the disc stops completely.

- The equipment is not removed until it cools down.

- Do not place fuel cans or other flammable items near the work site.

- You cannot neglect the availability of PPE, a first aid kit and knowledge of safety rules.

Another important condition is securing the surface or part being processed . For this purpose, vices, tripods and clamps are used. As an exception, only those objects that have a large mass and themselves remain immobile during processing can be used. You can also use the help of a partner who will hold the part in compliance with safety rules with an adjustable wrench.

Important! Keeping the part in a canopy is strictly prohibited.

Use of personal protective equipment

The operator of the angle grinder must also prepare his own safety, since the angle grinder casing only protects against sparks and the smallest abrasive fragments. Operator training involves the use of PPE - personal protective equipment:

- Plastic glasses.

- A jacket or shirt with thick sleeves without cuffs.

- Gloves.

- Mask or respirator.

- The respirator will protect the respiratory system from dust from sanding surfaces entering the lungs, and goggles have repeatedly protected the eyes of workers from bounced fragments of the disk or surface being treated.

Open safety glasses SecureFit 201 with 3M transparent lenses. Photo VseInstruments.ru

Place of work

The following mandatory rules apply to the place of work

- No clutter, freedom of movement for the worker.

- Possibility of rapid fire extinguishing.

- Ventilation.

- Availability of power supply.

- Lighting.

These requirements apply directly to the workplace for using an angle grinder, since during operation dust and sparks arise, and the angle grinder itself requires connection to an electrical network.

Securing workpieces

The grinder interacts with disks and other attachments on the working surface, which rotate at very high speed. The rotational movement of the nozzle is transmitted to light workpieces, which, being at rest, receive a translational vector and themselves move in space. To put it simply, a loose part will fly off the workbench if its mass is small and it is not secured. That is why the parts are fastened in a vice or under clamps.

Clamp vice Blacksmith WA1-100. Photo VseInstruments.ru

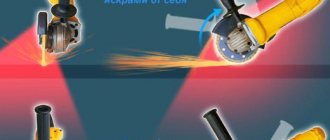

Operation of a working tool, initial start-up, breaks, where sparks should fly

You should choose a stable position for the body so that sparks do not fly under your feet when cutting. The cord should be strictly behind the body and not touch the working surface, so that there is no danger of it being wound around the circle. When working on the next part or when moving from place to place, the grinder must be turned off. The same should be done during power outages.

Important! Experts clearly recommend following one important rule: the direction of movement of the grinder should be the same as the direction of rotation of the disk. But in this case, sparks will fly onto the part, which may disrupt the view of the markings. But this rule almost completely covers the possibility of the disk getting stuck in the surface being processed.

Rules for using the grinder:

- You need to stand not in front of the grinder, but slightly to the side. This will allow you to protect yourself during the jet movement of the angle grinder in the event of a reverse strike.

- The protective cover protects the worker from injury in 90% of cases by containing the flying disc.

- There is no need to put pressure on the grinder ; it should process the surface under its own weight. The pressure can warp or destroy the disc.

- The grinder does not turn on if the disc is placed in the cut.

- If an angle grinder is used to cut a metal profile, then the cut begins at the thinnest point.

- If stone or ceramics are being cut and dust is generated, then it is better to choose a model with a vacuum cleaner that is connected to the casing.

- Cutting walls is dangerous due to the discovery of hidden cables or other communications. If they are touched, a backlash may occur, so you must stand strictly to the side of the cutting line.

How to cut a pipe with a grinder

To cut pipes with a grinder, it is recommended to use cutting wheels with a thickness of no more than 1 mm, otherwise the cut will be more difficult, and there will also be too many sparks and flying hot particles.

The technology for carrying out the work is as follows:

- The pipe is secured in a vice or secured in another way. In this case, the cut part should hang down. It is not allowed to place the workpiece between two supports and make a cut in the middle, as the cutting blade will jam (due to sagging pipe).

- Markings are applied using a strip of paper and masking tape. The ends of the tape should meet as accurately as possible. Home craftsmen recommend lowering the pipe into the liquid at the required angle, and then marking the cut line along the dry and wet boundary.

- The cut should be made from the top of the pipe, gradually lowering the angle grinder lower. The cutting disc should go along the very edge of the glued strip.

A large diameter pipe is cut a little differently, since the working part of the circle does not allow this to be done in one go. The wall is cut sector by sector, and the pipe is turned to the desired side.

Popular questions

First of all, users are interested in the following questions, which will be answered immediately.

Angle grinder (grinder) BORT BWS-1200U-SR. Photo 220Volt

Question: Can cut-off or sanding discs be used as one attachment to sand or cut different surfaces? That is, is it possible to use one nozzle for all work?

Answer: no, this is strictly prohibited. You won't be able to save money on this.

Question: if continuous home production is organized, how much will the electricity consumption meter count?

Answer: it should be understood that grinders have different powers. For example, for a 1200 W device that will be used continuously for 8 hours a day, the power consumption will be 210 W.

Question: if you buy an industrial grinder for your home, will it last forever?

Answer: industrial electrical appliances and tools are always highly wear-resistant, but one fact should be noted: a number of devices in the industrial sector operate on three-phase voltage. Household sockets are two-phase.

Accidents

As already mentioned, the use of grinders with strict adherence to safety rules is a guarantee of maintaining health, not only your own, but also those of others. If treated negligently, the angle grinder may “lead”, the disc may split or fly off the spindle . If you're lucky, it will fly past, but it can also be stopped... by the human body, which is extremely harmful to health)))

Maintenance and repair of safe angle grinders

If you do not have the skills of an electrician, then all work related to the electrical component, such as cleaning brushes, rewinding the electric motor, etc. – it’s better to entrust it to a professional. But you can check the integrity of the casing, spindle, threads of the clamping nut and flange yourself.

What kind of grinders are on the Russian market?

Angle grinders differ from each other not only in size and weight, but also in the speed of rotation of the disc. Heavier, mid-sized units will spin the disc at 6,000 to 7,000 rpm. For this type of device, the speed is low, but the power will “dissolve” fairly thick metal.

Please note that the lower the number of revolutions per 1 minute, the larger the diameter of the disk can be used to perform the work.

For household needs, angle grinders are often used, which weigh very little, which allows you to hold it with one hand, and have reduced dimensions. Such devices can reach speeds of up to 16,000 revolutions in 1 minute, and the disks used for work are very small. There are also very large devices that can be used, if only with a special stand, but they are used only for industrial needs and in general can be classified as miter saws. Such equipment will not be considered.

Device, operating principle and application possibilities

With the increase in power, a precedent has emerged for ensuring active and passive safety standards when using this tool. Modern angle grinders are equipped with many practical features and functional designs for working with metal, ceramics, wood and other surfaces.

The device of the grinder DIOLD MSHU-1.5-01. Photo 220Volt

To master the techniques of working with an angle grinder, you need to familiarize yourself in detail with its structure. Structurally, the tool consists of a mounting head - spindle , on which equipment - wheels for grinding or cutting, elongated or rectangular body one or two handles . The equipment depends on the requirements for the types of work using an angle grinder:

- Cutting of all kinds of materials, including high-strength composite alloys.

- Grinding and cleaning of surfaces.

Varieties

Grinders are available in three modifications according to their intended purpose:

- Industrial. They are distinguished by great power, as well as the possibility of long-term use every day, but they cannot be used continuously.

- Household. Their purpose is for occasional use to perform small amounts of work.

- For continuous production. They have a huge service life and are suitable for long-term and daily use.

Angle grinder INGCO AG30008 with a power of 3000 W. Photo VseInstruments.ru

In addition, grinders are divided according to a number of design features . They can be equipped with rotary or removable handles, a removable or built-in casing, and depending on the power, they have different weights and dimensions. The parameters are selected depending on the work for which the angle grinder is needed.

Tips for beginners and main mistakes

Experienced angle grinder users recommend that beginners buy an angle grinder from a well-known brand, with instructions in Russian and a convenient button located on the body “under your fingers.” To begin with, it is better to get a device with a power of up to 1 kW.

Such a tool costs about 5 thousand rubles, but personal safety and health are much more expensive - you cannot save much on an angle grinder.

Another tip concerns discs - it’s better to take branded ones and the right size. They are more expensive, but cheap Chinese ones are very thin and explode ten times more often.

Some grinder owners may argue about the thickness, arguing that a thin disc causes less injury in the event of an explosion, especially with a diameter of 115 mm.

But their opponents make a fairly compelling argument in favor of branded and thicker ones - they do not explode, unless used incorrectly. And the service life of the latter is longer.

The following are common mistakes when working with an angle grinder, which can result in disability or death.

Hands should not be near the disk or in close proximity - there is a high risk of being left without fingers or even without a hand

Mistakes when working with an angle grinder:

- Ignoring protective equipment - hands without gloves suffer from sparks, scale when working with metal, concrete particles and other things.

- Using your own legs as a vice when you need to hold bricks or other processed materials is a grave mistake.

- Unauthorized improvement of a tool that is not adapted to these needs , for example, a makeshift water supply, if the manufacturer indicates that the machine cannot be used with water, which can result in an electric shock.

Among the mistakes, the most important one should be highlighted - using an angle grinder while drunk or under the influence of psychotropic drugs. Which is strictly prohibited.

There is also no need to rush, leave the instrument plugged in or put it aside immediately after turning it off - first you need to wait until the disk stops.

We also have other useful articles on our website about another dangerous power tool - a welding machine. In which the rules for performing electric welding work for beginners and instructions for making horizontal and vertical seams are discussed.

To familiarize yourself with the material, please follow these links:

- Electric welding for beginners: rules and nuances of welding + analysis of the main mistakes

- How to weld vertical and horizontal seams using electric welding: analysis of methods + instructions

Types of nozzles

The range of replacement nozzles includes the following types:

- Brushes , which are used to polish and clean surfaces from rust or dirt.

- Circles with which you can cut metal or ceramics. It all depends on the purpose of the disk and its strength. As a rule, data is indicated directly on the disks.

Brush for angle grinder DEXX, disc, stranded tufts. Photo 220Volt.ru

The article described almost everything related to angle grinders. But the main thing that was thoroughly analyzed was safety precautions. You should pay the most careful attention to compliance with the rules of working with an angle grinder, as this not only guarantees the high-quality execution of work processes, but also the preservation of your own health.

Disc selection

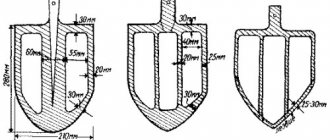

The diameter, thickness and type of disks are selected depending on the planned type of work. Diameters vary from 125 mm (small) to 250 mm (large, the most common) and affect the size (thickness and depth) of the cut.

A grinder for cutting metals requires a cutting disc with a thickness of 1.0-1.2 mm (professional ones reach 2.5 mm). Curly carving on thin metal requires the use of a disk with a small diameter or one that has already been used.

When cutting using discs of any diameter, it is necessary to use a protective coating - a casing. Essentially, this is a shield needed to catch small metal scraps generated during the cutting process.

Options for cutting and cleaning discs for grindersSource prom.st

Basic rules for cutting

When cutting a workpiece, it is important to make sure that you follow the basic rules. The cutting line should pass the person, but not rest against him. If a disc jams, the jet motion of the equipment will bypass the operator. It is important to provide protection with a casing. It should be located between the worker and the circle.

There is no need to apply excessive pressure on the tool. The unit will be able to cope with tasks using its own weight. Whereas overloads will cause the circle to skew. It is impossible to turn on the angle grinder when the disc is in the profile of the workpiece. You should start cutting the profile from the place where the cross section is smallest.

It is important to remember that cutting tiles, concrete and stone will generate a lot of dust. The respiratory system should be protected from it. Some manufacturers produce casings with a pipe for a vacuum cleaner. You can also suppress dust with water, directing the stream into the cut. If you need to work on cutting a wall, you must be prepared for the fact that reinforcement, pipe or cable may get under the circle. This will certainly cause a backlash. To avoid injury, stay clear of the equipment's offset line.

The nuances of cutting certain materials

When cutting concrete, use the following recommendations:

- Before starting work, check the concrete for the presence of embedded fittings, pipes, and electrical wiring (using a metal detector to find wiring).

- To reduce dust, moisten the work surface with water (for example, spray it with a spray bottle or brush).

- From time to time it is worth cooling the cutting element with water or air.

If you don’t have a tile cutter, you can also use a grinder to cut tiles. Specialists are able to cut even a perfectly even circle in tiles. Stone and tiles can be cut in two ways :

Wet (wet the work area with liquid).- Dry (no moisture).

When using the first option, cooling improves, but there will be a lot of dirt, and with the second there will be a lot of dust. The wet method is used for large volumes of upcoming work, and the dry method is used for one-time cutting. The material should be cut smoothly so that the disc sinks in with slight pressure, almost under the influence of the angle grinder’s own weight. This is required in order to prevent disk distortions and reduce the likelihood of jamming. If the process slows down, you should change the nozzle to a new one. And let's look at other life hacks for an angle grinder with your own hands.

- When you cut with a grinder, sparks often fly at you. If clothing is flammable, it may cause injury. To avoid the problem, take a regular insole (used sandpaper or a piece of rubber), as well as silicone glue (alternatively, use double-sided tape) and glue it all to the protective casing of the angle grinder. The advantage of the silicone adhesive composition is that it can be easily peeled off from the casing, and the result will be an interesting design. This way you will have a flexible extension of the casing. Such a splash guard will provide good protection from sparks, the main thing is that you choose a non-flammable material.

- Very durable profile pipes are usually coated with oil, which helps prevent rusting. If you have MDF in your workshop, then you can make a device for stripping the profile pipe (and any other metal) of grease, as well as paint or rust. To do this, take a regular grinder disc and transfer the outer and inner diameters to an MDF sheet. The circle can be cut with an electric jigsaw, but you can also use crowns with a suitable diameter. Next, attach the homemade disk to the device and you can clean the wires. If you take car polish, you can polish the metal.

- The key to the grinder is annoying because it is sometimes difficult to find when you need it. There is a fairly simple way to disassemble a drive without a key, and we note that it is better to do everything with gloves and with the device turned off.

To begin, spin the grinder disk in the direction opposite to the movement (on the back of the grinder, an arrow indicates the direction of rotation of the disk), make three turns with a sharp movement of your hand. Then sharply twist the disk in the opposite direction. The nut that holds the disk will unwind, and you can easily unscrew it by hand and remove the disk.

- The method is useful for cutting off the edge of a profile pipe, so that the bottom wall is cut at the same angle as the top (we do everything at an angle of 90 degrees). Take a piece of metal with a thickness of 0.1-0.2 cm and drill a hole so that it stands 0.2-0.3 cm away from the cut disk and screw it with an M8 bolt. Next, make a mark with a square, it should be marked at a right angle, and then cut off the tip of the profile pipe. Please note that this method has two drawbacks - the bolt limits the length of the cutting part, and the size of the disk limits its height.

- An excellent life hack if you need to cut a round pipe at a strictly right angle using a grinder. You will need a sheet of paper with straight edges, tape, a pipe and a power tool. Wrap the sheet around the pipe, tightly, and after you have made one circle, the edges should meet perfectly. Next, cut everything along the edge of the sheet with a grinder, and get a perfect 90 degrees.

Use an angle grinder only when you know all the operating and safety rules. The working part must rotate in the direction of movement of the tool. Before starting the process, be sure to turn on the device at idle speed. Also, vibration, heating of the angle grinder, and also extraneous sounds should be absent. Wheels should be used without defects, and the most dangerous part may be kickback. To avoid this, try not to jam the wheel when cutting to a fault.