How much does 1 kg of cast iron cost?

Cost of cast iron scrap

| Category | Price per kg | Price per ton |

| 17A - cast iron scrap overall | 6-7 rubles | 9000-10000 rubles |

| 19A - dimensional cast iron scrap, in pieces | 6-7 rubles | 8500-9000 rubles |

| 20A - oversized scrap, piece weight no more than 5 tons | 6-7 rubles | 9000-10500 rubles |

| 22A - oversized scrap (plumbing waste) | 6-7 rubles | 8500-9000 rubles |

By deciphering the grades of materials

Decipher the grades of iron-carbon and non-ferrous alloys:

BSt1kp; 50; U7A; SCH25; 30Х3МФ; ShH4;25GFL; LN65-5; BrO8Ts4.

· BSt1kp – carbon structural steel of ordinary quality, grade 1, group B – with a guaranteed chemical composition, boiling.

· 50 – carbon structural steel, high quality, quiet, with an average carbon content of 0.5%.

· U7A – high-quality carbon tool steel, carbon content – 0.7%.

· SCh25 – gray cast iron, tensile strength 250 MPa.

· 30Х3МФ – high-quality alloy steel, average carbon content 0.3%. Alloying elements X - chromium, content 3%, M - molybdenum - up to 1.5%, F vanadium - up to 1.5%.

· ШХ4 – ball bearing steel, chromium content 0.4%.

· 25GFL – alloy steel for shaped casting, average carbon content – 0.25%. Alloying elements: G – manganese – up to 1.5%, F – vanadium – up to 1.5%.

· LN65-5 – deformable brass. Copper content – 65%, nickel – 5%, the rest zinc – 30% (100-65-5=30%).

· BrO8Ts4 – casting bronze. Tin content is 8%, zinc is 4%, the rest is copper -88% (100-8-4=88%).

Appendix B

Symbols of material grades

| Material | Designation |

| Become | |

| Carbon steels of ordinary quality | The letters “St” and a number (from 0 to 6), indicating the brand number (St1, St2). An increase in number indicates an increase in carbon content and tensile strength. Depending on the guaranteed properties, steels are divided into three groups: A – with guaranteed mechanical properties, B – with guaranteed chemical composition, C – with guaranteed mechanical properties and chemical composition, which are indicated to the left of the letters “St” (group A is not indicated). The indices to the right of the brand number indicate the degree of deoxidation of the steel: kp - boiling, sp - calm, ps - semi-calm. Between the index and the brand number there may be the letter “G” - increased manganese content. |

| Carbon quality steels | Double-digit numbers: 05,08,10,...85, indicating the average carbon content in hundredths of a percent. After the numbers there are letters indicating the degree of deoxidation of the steel: if the steel is boiling - kp, if it is semi-calm - ps, if there are no letters - the steel is calm. The letter “G” in steel grades indicates a high manganese content. |

| Carbon tool steels | The letter “U” and numbers showing the average carbon content in tenths of a percent (U7, U8). If the steel is high quality, then the letter “A” (U8A) is placed to the right of the number. |

| Automatic steels | The letter “A” and numbers showing the average carbon content in hundredths of a percent. The letter “G” after the number indicates a high content of manganese (A40G). |

| Carbon steels for shaped castings | Numbers followed by the letter “L”. The numbers show the average carbon content in hundredths of a percent (15L, 20L). |

| Alloy steels | Letters and numbers. The first two digits indicate the average carbon content: if there are two or three numbers - in hundredths of a percent, if one - in tenths, if there is no number - the carbon content is about 1%. The letters behind the numbers mean that the steel contains alloying elements (for the designation of elements, see Table 5) (20ХН3А, 30ХГС). The numbers after the letters indicate the approximate content of the alloying element in whole percent units. If the alloying element content is less than 1.5%, the figure is missing. The letter “A” at the end of the mark means that the steel is high quality. If there is a letter “SH” at the end of the brand, the steel is of especially high quality. |

| Bearing steels | The letters “ШХ” and numbers indicating the chromium content in tenths of a percent. The letters after the numbers indicate the presence of additional alloying elements (Table 5). |

| Alloy steels for shaped castings | Numbers and letters. The two numbers at the beginning of the brand indicate the average carbon content in hundredths of a percent; the letters behind them indicate alloying elements (Table 5). The numbers after the letters indicate the approximate content of the alloying element in whole units of percent. The letter “L” is placed at the end of the stamp (30ХМЛ). |

| High speed steels | The letter “P”, the number after which indicates the tungsten content in percent (P18). Alloying elements in steels are designated by letters in accordance with Table 5, the numbers behind them indicate their quantity. |

| Cast iron | |

| Gray cast iron | The letters “СЧ” and a two-digit number indicating the minimum tensile strength in MPa ·10-1 (СЧ 10) |

| Malleable iron | The letters "KCH". The first two-digit number indicates the temporary tensile strength in MPa ·10-1, the second number indicates the relative elongation in% (CN 30-6). |

| Ductile iron | The letters “HF” and a two-digit number indicating the tensile strength in MPa ·10-1 (HF35). |

| Alloy cast iron | The first letter is “H” and subsequent letters indicating the presence of alloying elements. The numbers indicate sequentially the average content of alloying elements as a percentage. The letter “Ш” at the end of the mark means that the graphite in cast iron has a spherical shape (CHH32). |

| Non-ferrous alloys based on aluminum | |

| Foundry (Silumin) | The letters “AL”, followed by the alloy number (AL2). |

| Deformable, strengthened by heat treatment (Duralumin) | The letter "D" followed by the alloy number. |

| Deformable, not hardened by heat treatment | The letters “AM”, if the alloying component is manganese, then AMts, if magnesium, then Amg. The number shows the content of the alloying component (AMg2). |

| Non-ferrous copper-based alloys | |

| Deformable brass | The first letter “L” is brass and other letters indicate the content of alloying elements. The first number is the percentage of copper, the rest is the content of alloying elements (LA77-2). |

| Foundry brasses | The first letter “L” is brass, then the letters showing alloying elements. The numbers behind the letters indicate the percentage of the alloying element (LTs16K4). |

| Deformable bronzes | The first two letters "Br" are bronze and the subsequent letters show only alloying elements. The numbers indicate their percentage (BrO 4-4). |

| Casting bronzes | The first two letters are “Br” - bronze, then letters showing alloying elements. The numbers behind the letters indicate the percentage of the alloying element (BrO10C10). |

| Anti-friction alloys | |

| Babbitts | The letter “B” and a number indicating the tin content in percent (B88). |

Appendix D

Symbols of the main elements in grades of metals and alloys

| Element | Symbol | Accepted designation of elements in grades of metals and alloys | Element | Symbol | Accepted designation of elements in grades of metals and alloys | ||

| Black | Colored | Black | Colored | ||||

| Nitrogen | N | A | — | Neodymium | Nd | — | Nm |

| Aluminum | Al | YU | A | Nickel | Ni | N | N |

| Barium | Ba | — | Br | Niobium | Nb | B | Np |

| Beryllium | Be | L | — | Tin | Sn | — | ABOUT |

| Bor | B | R | — | Osmium | Os | — | OS |

| Vanadium | V | F | To you | Palladium | Pd | — | front |

| Bismuth | Bi | In and | In and | Platinum | Pt | — | Pl |

| Tungsten | W | — | — | Praseodymium | Pr | — | Etc |

| Gadolinium | Gg | Um | Um | Rhenium | Re | — | Re |

| Gallium | Ga | Gl | Gl | Rhodium | Rh | — | Rd |

| Hafnium | Hf | — | Gf | Mercury | Hg | — | R |

| Germanium | Ge | — | G | Ruthenium | Ru | — | RU |

| Holmium | Ho | — | GOM | Samarium | Sm | — | Myself |

| Dysprosium | Dy | — | DIM | Lead | Pb | — | WITH |

| Europium | Eu | — | Ev | Selenium | Se | E | ST |

| Iron | Fe | — | AND | Silver | Ag | — | Wed |

| Gold | Au | — | Evil | Scandium | Sc | — | SCM |

| Indium | In | — | In | Antimony | Sb | — | Su |

| Iridium | Ir | And | AND | Thallium | Tl | — | Tl |

| Ytterbium | Yb | — | ITM | Tantalum | Ta | — | TT |

| Yttrium | Y | — | THEM | Tellurium | Te | — | T |

| Cadmium | Cd | CD | CD | Terbium | Tb | — | Volume |

| Cobalt | Co | TO | TO | Titanium | Ti | T | TPD |

| Silicon | Si | WITH | Kr(K) | Thulium | Tu | — | TUM |

| Lanthanum | La | — | La | Carbon | C | U | — |

| Lithium | Li | — | Le | Phosphorus | P | P | F |

| Lutetium | Lu | — | Lum | Chromium | Cr | X | X(Xp) |

| Magnesium | Mg | Sh | Mg | Cerium | Ce | — | Xie |

| Manganese | Mn | G | Mts(Mr) | Zinc | Zn | — | C |

| Copper | Cu | D | M | Zirconium | Zr | C | TsEV |

| Molybdenum | Mo | M | — | Erbium | Er | — | Erm |

Decipher the grades of iron-carbon and non-ferrous alloys:

BSt1kp; 50; U7A; SCH25; 30Х3МФ; ShH4;25GFL; LN65-5; BrO8Ts4.

· BSt1kp – carbon structural steel of ordinary quality, grade 1, group B – with a guaranteed chemical composition, boiling.

· 50 – carbon structural steel, high quality, quiet, with an average carbon content of 0.5%.

· U7A – high-quality carbon tool steel, carbon content – 0.7%.

· SCh25 – gray cast iron, tensile strength 250 MPa.

· 30Х3МФ – high-quality alloy steel, average carbon content 0.3%. Alloying elements X - chromium, content 3%, M - molybdenum - up to 1.5%, F vanadium - up to 1.5%.

· ШХ4 – ball bearing steel, chromium content 0.4%.

· 25GFL – alloy steel for shaped casting, average carbon content – 0.25%. Alloying elements: G – manganese – up to 1.5%, F – vanadium – up to 1.5%.

· LN65-5 – deformable brass. Copper content – 65%, nickel – 5%, the rest zinc – 30% (100-65-5=30%).

· BrO8Ts4 – casting bronze. Tin content is 8%, zinc is 4%, the rest is copper -88% (100-8-4=88%).

Appendix B

Symbols of material grades

| Material | Designation |

| Become | |

| Carbon steels of ordinary quality | The letters “St” and a number (from 0 to 6), indicating the brand number (St1, St2). An increase in number indicates an increase in carbon content and tensile strength. Depending on the guaranteed properties, steels are divided into three groups: A – with guaranteed mechanical properties, B – with guaranteed chemical composition, C – with guaranteed mechanical properties and chemical composition, which are indicated to the left of the letters “St” (group A is not indicated). The indices to the right of the brand number indicate the degree of deoxidation of the steel: kp - boiling, sp - calm, ps - semi-calm. Between the index and the brand number there may be the letter “G” - increased manganese content. |

| Carbon quality steels | Double-digit numbers: 05,08,10,...85, indicating the average carbon content in hundredths of a percent. After the numbers there are letters indicating the degree of deoxidation of the steel: if the steel is boiling - kp, if it is semi-calm - ps, if there are no letters - the steel is calm. The letter “G” in steel grades indicates a high manganese content. |

| Carbon tool steels | The letter “U” and numbers showing the average carbon content in tenths of a percent (U7, U8). If the steel is high quality, then the letter “A” (U8A) is placed to the right of the number. |

| Automatic steels | The letter “A” and numbers showing the average carbon content in hundredths of a percent. The letter “G” after the number indicates a high content of manganese (A40G). |

| Carbon steels for shaped castings | Numbers followed by the letter “L”. The numbers show the average carbon content in hundredths of a percent (15L, 20L). |

| Alloy steels | Letters and numbers. The first two digits indicate the average carbon content: if there are two or three numbers - in hundredths of a percent, if one - in tenths, if there is no number - the carbon content is about 1%. The letters behind the numbers mean that the steel contains alloying elements (for the designation of elements, see Table 5) (20ХН3А, 30ХГС). The numbers after the letters indicate the approximate content of the alloying element in whole percent units. If the alloying element content is less than 1.5%, the figure is missing. The letter “A” at the end of the mark means that the steel is high quality. If there is a letter “SH” at the end of the brand, the steel is of especially high quality. |

| Bearing steels | The letters “ШХ” and numbers indicating the chromium content in tenths of a percent. The letters after the numbers indicate the presence of additional alloying elements (Table 5). |

| Alloy steels for shaped castings | Numbers and letters. The two numbers at the beginning of the brand indicate the average carbon content in hundredths of a percent; the letters behind them indicate alloying elements (Table 5). The numbers after the letters indicate the approximate content of the alloying element in whole units of percent. The letter “L” is placed at the end of the stamp (30ХМЛ). |

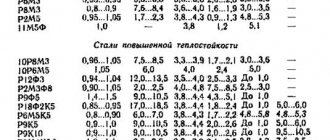

| High speed steels | The letter “P”, the number after which indicates the tungsten content in percent (P18). Alloying elements in steels are designated by letters in accordance with Table 5, the numbers behind them indicate their quantity. |

| Cast iron | |

| Gray cast iron | The letters “СЧ” and a two-digit number indicating the minimum tensile strength in MPa ·10-1 (СЧ 10) |

| Malleable iron | The letters "KCH". The first two-digit number indicates the temporary tensile strength in MPa ·10-1, the second number indicates the relative elongation in% (CN 30-6). |

| Ductile iron | The letters “HF” and a two-digit number indicating the tensile strength in MPa ·10-1 (HF35). |

| Alloy cast iron | The first letter is “H” and subsequent letters indicating the presence of alloying elements. The numbers indicate sequentially the average content of alloying elements as a percentage. The letter “Ш” at the end of the mark means that the graphite in cast iron has a spherical shape (CHH32). |

| Non-ferrous alloys based on aluminum | |

| Foundry (Silumin) | The letters “AL”, followed by the alloy number (AL2). |

| Deformable, strengthened by heat treatment (Duralumin) | The letter "D" followed by the alloy number. |

| Deformable, not hardened by heat treatment | The letters “AM”, if the alloying component is manganese, then AMts, if magnesium, then Amg. The number shows the content of the alloying component (AMg2). |

| Non-ferrous copper-based alloys | |

| Deformable brass | The first letter “L” is brass and other letters indicate the content of alloying elements. The first number is the percentage of copper, the rest is the content of alloying elements (LA77-2). |

| Foundry brasses | The first letter “L” is brass, then the letters showing alloying elements. The numbers behind the letters indicate the percentage of the alloying element (LTs16K4). |

| Deformable bronzes | The first two letters "Br" are bronze and the subsequent letters show only alloying elements. The numbers indicate their percentage (BrO 4-4). |

| Casting bronzes | The first two letters are “Br” - bronze, then letters showing alloying elements. The numbers behind the letters indicate the percentage of the alloying element (BrO10C10). |

| Anti-friction alloys | |

| Babbitts | The letter “B” and a number indicating the tin content in percent (B88). |

Appendix D

Symbols of the main elements in grades of metals and alloys

| Element | Symbol | Accepted designation of elements in grades of metals and alloys | Element | Symbol | Accepted designation of elements in grades of metals and alloys | ||

| Black | Colored | Black | Colored | ||||

| Nitrogen | N | A | — | Neodymium | Nd | — | Nm |

| Aluminum | Al | YU | A | Nickel | Ni | N | N |

| Barium | Ba | — | Br | Niobium | Nb | B | Np |

| Beryllium | Be | L | — | Tin | Sn | — | ABOUT |

| Bor | B | R | — | Osmium | Os | — | OS |

| Vanadium | V | F | To you | Palladium | Pd | — | front |

| Bismuth | Bi | In and | In and | Platinum | Pt | — | Pl |

| Tungsten | W | — | — | Praseodymium | Pr | — | Etc |

| Gadolinium | Gg | Um | Um | Rhenium | Re | — | Re |

| Gallium | Ga | Gl | Gl | Rhodium | Rh | — | Rd |

| Hafnium | Hf | — | Gf | Mercury | Hg | — | R |

| Germanium | Ge | — | G | Ruthenium | Ru | — | RU |

| Holmium | Ho | — | GOM | Samarium | Sm | — | Myself |

| Dysprosium | Dy | — | DIM | Lead | Pb | — | WITH |

| Europium | Eu | — | Ev | Selenium | Se | E | ST |

| Iron | Fe | — | AND | Silver | Ag | — | Wed |

| Gold | Au | — | Evil | Scandium | Sc | — | SCM |

| Indium | In | — | In | Antimony | Sb | — | Su |

| Iridium | Ir | And | AND | Thallium | Tl | — | Tl |

| Ytterbium | Yb | — | ITM | Tantalum | Ta | — | TT |

| Yttrium | Y | — | THEM | Tellurium | Te | — | T |

| Cadmium | Cd | CD | CD | Terbium | Tb | — | Volume |

| Cobalt | Co | TO | TO | Titanium | Ti | T | TPD |

| Silicon | Si | WITH | Kr(K) | Thulium | Tu | — | TUM |

| Lanthanum | La | — | La | Carbon | C | U | — |

| Lithium | Li | — | Le | Phosphorus | P | P | F |

| Lutetium | Lu | — | Lum | Chromium | Cr | X | X(Xp) |

| Magnesium | Mg | Sh | Mg | Cerium | Ce | — | Xie |

| Manganese | Mn | G | Mts(Mr) | Zinc | Zn | — | C |

| Copper | Cu | D | M | Zirconium | Zr | C | TsEV |

| Molybdenum | Mo | M | — | Erbium | Er | — | Erm |