In construction work, laying a solid foundation, the construction of various metal structures is required, where it is necessary to use reinforcement of different diameters and sizes.

Concrete buildings experience the greatest loads in places of bends and corners, and this leads to rapid destruction.

Therefore, steel frames used for strengthening make it possible to give the structure durability and wear resistance. How to properly prepare and bend reinforcement for foundations, what machines or devices exist for this will be discussed later in this article.

Using steel pipes for bending reinforcement

After calculating the amount of reinforcement and purchasing it, it becomes necessary to carry out work on it with your own efforts. This can be done using some available tools. The first method involves the use of steel pipes, which are first dug into the ground or concreted. The inner diameter of the pipe should be small.

The fittings are lowered into the pipe to the required length and the outer part is bent to the side until the required angle of inclination is obtained. Helpers may be needed when bending. To simplify the procedure, you can additionally put a second piece of pipe on the rod.

When arranging the foundation, you can use another method. To do this, you will need two pipes, the diameter of which should not be much larger than the diameter of the rod. You also need to pay attention to the length of the pipes; you will need to put in less effort if you choose a longer pipe.

• Two pins are driven into the ground.

• Pipes are put on the rod on both sides.

• By supporting the reinforcement on the pin, it is quite easy to bend it, reaching the required radius of curvature.

Instead of pins, you can use other similar devices at hand.

Using welding to bend reinforcement

The use of welding is possible in cases where there are no requirements to maintain thickness. In this case, the reinforcement is heated at the site of the future bend. The metal becomes ductile and bends easily.

You can also heat the rod using a blowtorch. In this case, the reinforcement must be secured in a vice if it is not possible to ask someone for help. After heating the rod, it is bent with a hammer or by hand.

There are many other methods for heating reinforcement, but it should be remembered that this bending method is not recommended for structures intended for high loads. Therefore, it is better to consult with specialists.

Bend a pipe at home

When installing heating pipes, it may be necessary to bend the pipe. This procedure is performed as follows.

• A spring of the same diameter is inserted into the pipe, which will prevent possible rupture. Then they begin bending the pipe. Remove the springs using wire.

• Another method involves using sand to fill the pipe. After this, it is clamped in a vice and heated at the intended bend. The degree of heating of the pipe is judged by its color, which should turn bright red. You can make sure that the required temperature has been achieved by holding the paper close to the pipe. If it is charred, then the metal is ready for bending. Galvanized structures should not be bent when hot, as this may damage the coating.

• Bending pipes for heating a private house with thick walls is carried out using a grinder and welding. Having calculated the radius of the required curvature, cuts are made. After bending the pipe, the cuts made are welded.

Plastic pipe bending

When bending plastic pipes used in heating systems, the following steps are performed.

• Using fiberboard, make a frame that will give the pipe the desired shape.

• In order to prevent chips and scratches when bending plastic, the frame is filled with silicone, selected according to the shape.

• The pipe is then placed in the completed shell and heated.

• As the plastic heats up, it will begin to fill the frame, giving it the desired shape.

• After ten minutes, the pipe is removed and allowed to cool.

- BASKET

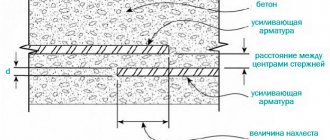

Reinforcement in construction is necessary, first of all, for reinforcing concrete. This connection allows you to transfer compressive and tensile forces to the reinforcing bars. This is simply necessary when building a foundation, since concrete has little resistance to such loads.

| Armature |

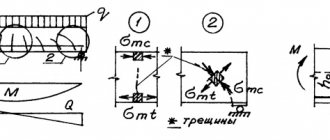

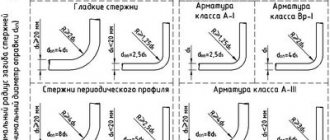

It is not correct to reinforce with connections made of straight rods; this weakens the structure, which can lead to various unpleasant consequences, for example, delamination of the foundation. Therefore, bending of reinforcement is necessary both to create corner ties of curved rods and to create various elements, for example, legs, hooks, etc. Fiberglass rods can only be bent at the enterprises that produce them. If you try to bend it with your own strength, it will simply burst. Metal reinforcement is bent strictly mechanically; no sharp corners should be allowed at the bending point.

Read also: Diamond burs for engravers

There are still several popular methods that are not advisable to use for bending rods. This:

- The angle grinder undercut the bend area

- Heating the bend area to a high temperature with a blowtorch, etc.

These manipulations greatly reduce the characteristics of the reinforcement, which can lead to their destruction. And it is better to use them only when the result does not affect the quality of the entire structure.

Bent reinforcement in concrete.

Any type of metal rod bends only cold without any cuts or other violations of the integrity of the rod. Moreover, each type can be bent to a certain angle, after which it will lose strength. For example, type A3 reinforcement can be bent at an angle of no more than 90 degrees without loss of strength. When bent 180 degrees, strength decreases by at least 10%.

All equipment for bending reinforcement can be divided into several categories

Drive equipment operates according to the following scheme

A thrust roller is fixed to the stand, and a disk is installed on the vertical shaft, on which the fingers (bending and central) are fixed. Bend rods are placed between them. When the disk begins to rotate in a horizontal plane, the laid rod rests against the roller and bends under the influence of the bending pin. The bending finger moves from the outside of the rod.

Bending machines, depending on the rods, are also divided into equipment:

- For bending rods from 3 to 20 mm.

- For bending rods from 20 to 40 mm.

- For bending rods from 40 to 90 mm.

- For bending rods from 3 to 90 mm.

Hydraulic machines are usually used when it is necessary to make several complex bends at an angle of up to 180 degrees. Such equipment bends rods without any defects that strain the metal.

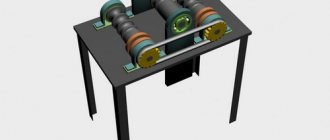

Manual bending equipment comes in many types and can even be portable. Usually installed on a workbench for more convenient use. Much cheaper than other options and completely easy to use. The tool is suitable for small amounts of work.

Before purchasing a tool, you must know the scope of work, timing and diameter of the rods to be bent. In addition, you need to remember that the outer part of the reinforcement is more susceptible to tensile loads, while the inner part is more susceptible to compression. If you choose the wrong equipment or use it not according to the instructions, you can easily damage both the fittings and the machine. Therefore, before use, you should correctly configure the structure and, when using it, correctly clamp the reinforcing bar in it.

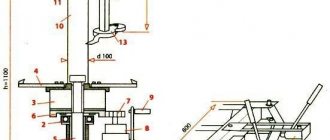

One of the devices for bending reinforcement

When special care and precision is not required, you can bend the rods even with your own hands. If you have strong hands and a rod with a diameter of 8 mm, this is not a problem. Two steel pipes will facilitate the process and improve the quality of the bend. The longer the pipes, the larger the diameter of the rod that can be bent.

The process itself is completely simple:

- The rod is inserted into the first, fixing pipe to the point of bending.

- The second pipe will be used as a lever. it is put on the other end of the reinforcement and guided in the desired direction.

- The reinforcement is bent.

For convenience, the fixing pipe is rigidly fixed in a vice, buried in the ground, etc.

A modification is also possible when both pipes are firmly buried or driven into the ground. The rod is inserted between the pipes and bent into the desired position.

An example of a homemade machine for bending reinforcement

If you have started building a new house, then to strengthen the concrete foundation you will need to make a reinforced frame. Reinforcing rods are produced, like any rolled metal, exclusively in straight form. But in order to make a frame from reinforcement, it must be bent in a certain way. Moreover, this operation will have to be performed directly at the construction site. There is only one rational solution - this is to make a machine for bending reinforcement with your own hands.

Read also: Do-it-yourself wood miter saw

The time and money spent on a homemade machine for bending reinforcement will pay off even at the stage of building the foundation of your house. It can also be used in the future. For example, for the manufacture of embedded parts, such as window or door lintels. But even after this, it will be useful to you more than once for assembling various steel structures.

Reinforcement bending machines

According to the type of force with which the bending force is created, machines are classified into:

- manual,

- hydraulic,

- pneumatic,

- electromechanical,

- electromagnetic.

Using hand-held machines, it is possible to produce products from reinforcement with a diameter of up to 14 mm. If you need to manually bend reinforcement with a diameter of more than 14 mm. Then you should use the correct plate and a set of special keys. Manual production of curved reinforcing bars is advisable only for small volumes of work. Increasing the productivity of such manual labor is achieved by using machines for simultaneous processing of several reinforcing bars.

Other types of machines are distinguished by high productivity, precision of the manufactured configuration and the ability to bend reinforcement of any diameter. At the same time, they usually have various functions that increase productivity, small dimensions and the ability to operate in an automated mode.

Bending reinforcement using special equipment allows you to avoid twisting of the product around the central axis. In addition, products bent in this way are characterized by high accuracy of geometric shape. This achieves a reduction in time and labor costs for performing operations to install reinforcement parts in the required design position, which creates a positive economic effect on any construction site.

More information

When creating the structural frame of concrete work, bending and cutting of reinforcement (steel rods to strengthen the concrete) is very often necessary. It is an easy-to-work material that is often used in landscaping, art, and other projects that require metal that bends easily. Conventional reinforcement is distinguished by its nominal diameter, which varies in increments of 1/8 inch (that is, “number 4” reinforcement has a nominal diameter of 1/2 inch (15 mm)). Reinforcement up to number 4, as a rule, can be bent and cut by hand. Larger diameter rebar is not usually used except for technical or industrial concrete work and usually requires special equipment such as hydraulic shears and bending machines.

For this article, we will assume that 1/2 inch rebar (number 4) is used, which is common and used in landscaping and residential concrete work.

- Tight bends almost always require the use of a vise, jig, or special tool.

- The reinforcement can be heated with a torch for precise control of the bending process. However, this is unlikely to be needed when working with reinforcement having a nominal diameter of 1/2 inch (15 mm).

The principle of bending reinforcement

Bending a reinforcing bar is a process of controlled change in the direction of the central axis. In this case, at the point of deformation, some layers of metal will stretch, while others will compress.

One of the main determining factors during bending is the amount of force applied to the site of deformation. It directly depends on the type of steel and the cross-sectional diameter of the reinforcement. Thus, you can immediately decide that the better and thicker the reinforcing bar, the more force you will need to apply to bend it.

These definitions should serve as the basis for further calculations when making a device for bending reinforcement with your own hands.

Three methods of tying reinforcement cages

To form the metal frame of the base, three strapping methods are used:

- Welding. At first glance, welding is the simplest and most effective way to connect reinforcement, but in practice everything looks different. During welding, the metal is heated to high temperatures and deformed, which results in a partial loss of rigidity. You also have to hire a professional welder who knows about the properties of the metal and can avoid burning it, and this is an additional financial expense. There is also a risk of destruction of the welding site during operation of the industrial vibrator. Difficulties arise if you bend metal close to the welding site.

- Connection using bent wire or plastic clamps (ties). This method is popular among many developers, since the connection can be made with your own hands in a matter of minutes. If flexible wire is used, then a special tool must be used to connect the links. Plastic clamps are more reliable than wire, but are more expensive. The connection diagram is similar, only then you have to bend the rods at the required angle.

- Overlapping. This method involves overlapping reinforcement with further fixation with wire. It is practiced more for horizontal belts made of mesh, and a vertical smooth rod is used inside the joint.

Any of the above methods can be implemented with your own hands. In this case, you have to bend the metal, which is quite problematic, given the rigidity of the reinforcement and its minimum diameter for horizontal chords of 12 mm.

How to bend reinforcement without a special device

And yet, let's start with the fact that you urgently need to bend a small amount of thin metal rod. To do this, we will look at several ways to bend reinforcement using improvised means.

Here it is worth knowing that when trying to bend, especially alloyed reinforcement, with your own hands you need to consciously calculate your actions, otherwise this can lead to serious injuries. Alloyed rolled metal, if you try to deform it, will try in every possible way to spring back and can cause irreparable harm to your health. So be careful and attentive.

Let us highlight the three simplest ways to bend reinforcement with a diameter of up to 8 mm yourself without the use of special devices, namely:

- Using two pieces of metal pipe. So, we will need tubes with a diameter of 15 mm with a length of 0.5 and 1 meter, which we put on the fittings. We stand on a half-meter piece of pipe with our feet, and, accordingly, we begin to lift the meter piece to the bend angle we need.

- If a five-centimeter piece of pipe 25-32 mm in diameter is electric welded to a one and a half meter metal pipe of 32 mm in diameter or a 50 mm steel angle, you will get a universal bending lever. All that remains is to either stand on the reinforcement or rest it against something strong.

- Not very long pieces of reinforcement can be bent using a large vice and a sledgehammer. Only with this method you shouldn’t rush and you need to hit with a little force, stretching the process, otherwise you can simply break the reinforcing bar.

The main disadvantage of using such methods for bending reinforcement is that the turning radius is quite large and often the angle turns out to be somewhat curved and does not lie with its sides strictly in the same plane.

Although, with good physical data and small diameters of the metal rod, these methods, as a rule, in practice are the most versatile benders at home.

Preparation of materials and tools

Before making a bending machine, read the available drawings or make your own. The thickness of the reinforcing rod and their number are important as initial data. The safety factor of the device, which exceeds the effort required to bend the existing reinforcing bars, is chosen to be at least three times larger if the business is put into production and you are bending reinforcement for a large number of customers, or a grandiose construction project is planned.

If the drawing is selected, the following tools and accessories will be required.

- Grinder with a set of cutting and grinding discs. Without it, sawing a massive profile and reinforcing bars is difficult.

- Electric drill and suitable high-speed steel drill bits.

- Welding installation and electrodes.

- A hammer, a sledgehammer, powerful pliers, a chisel (file), a center punch and several other tools that no mechanic can do without.

- Vise for workbench. Since the structure is powerful, it must be fixed.

The materials you will need are:

- corner profile (25*25 mm) 60 cm long;

- steel rod (diameter 12-25 mm);

- bolts 2*5 cm, nuts for them (20 mm in inner diameter), washers for them (can be screwed).

The device you will make weighs more than one kilogram. The reinforced weight and massiveness of the entire structure will provide the strength required for bending the reinforcement.

How to make a device for bending reinforcement

If, nevertheless, the volume of work is large and you have enough technical knowledge, then anyone can make a manual bending machine for reinforcement with their own hands, so it’s all the more not worth buying it on the construction market.

Before starting production, it is necessary to make detailed drawings of the components of the future device. To do this, it is recommended to familiarize yourself with ready-made samples on the Internet, made according to a standard scheme, or choose some other technique than bending reinforcement.

A simple do-it-yourself reinforcement bender is easiest to do, based on the general principle of operation of this kind of device, namely, consisting of three main parts:

- massive base,

- rotating mechanism in the form of a large lever,

- strong support.

To make such a device, improvised materials and tools available in any normal garage are quite suitable. So, let's prepare the necessary tools for this, here we will need:

- angle grinder with cutting wheels and grinding disc,

- electric drill with a set of metal drills,

- electric welding machine with electrodes,

- standard set of hand tools.

Read also: What is the difference between a cyclone filter and a container?

Although an important step is the preparation of components and assemblies, here we will try to adapt various available materials. As a last resort, what is missing can be borrowed either from a neighbor or purchased in addition on the construction market.

Sequencing

- Let's make the base. To do this, we take sheet metal 3-5 mm thick, measuring 100 by 200 mm, or you can take a piece of channel size 10-15, 200-300 mm long. We drill holes in the corners of the base to allow fastening to a workbench or other massive object. An axial stop is firmly welded in the center of the structure using electric welding. This is a steel shaft with a height of 50 mm and a diameter of 14 mm. For this part, you can take any M14 bolt of suitable size, the head of which must be sanded off, leaving a thickness of 3 mm - this will make it possible to create a strong welded connection with the base.

- We make a rotating mechanism. A steel strip 5 mm thick, 50 mm wide and at least one meter long is suitable for this. In the absence of a strip of the required length, you can take a shorter one, but weld the length of the lever using a steel pipe 32-50 mm in diameter. To one edge of the strip we electric weld a piece of metal pipe 50 mm long and 15 mm in diameter, which will fit like a roller on the axial stop. We retreat 50 mm from the roller along the longitudinal axis and weld a rotary stop, for which an M10 steel bolt, also with a pre-ground head, is suitable. You can also make and put a ring on the rotary stop, which will serve as a roller, which will improve the operation of the device. As an option, you can make a lever from a 50 mm steel angle; to do this, you need to cut off 50 mm of the shelf vertically at the point of attachment to the axial stop; the remaining part of the shelf will serve as a rotary stop.

- We electric weld a fixed stop to the base, for which a 50 mm piece of angle 50-100 mm long is suitable. The place of its attachment should be 100-200 mm from the axial stop with a displacement from the central axis of the base of no more than 20 mm, which is determined by the thickness of the reinforcement.

- We assemble the finished structure. We firmly attach the bases of our finished device to a mechanic’s workbench or other similar massive object in the surrounding environment. We put the rotating mechanism roller with a lever on the axial stop.

- We run in the finished machine for bending reinforcement and check its operation at idle, using soft metal for this. If everything works, then we begin to manufacture the parts we need from the reinforcement.

If the machine for bending reinforcement has its own stationary frame, then it is worth advising to make a couple of additional improvements to it, namely:

- apply linear markings on both sides of the axial stop, which will allow you to measure the length of the bent part of the bar without using a tape measure;

- Apply radial markings of the main angles of 30, 45 and 60 degrees around the axial stop, which will also make working on such a machine much more convenient.

Do-it-yourself manual reinforcement bender. Drawing, description

In order to make a simple reinforcement bender you will need:

- steel base, which can be used as a part of a steel sheet with a thickness of at least 6 mm;

- steel angle with dimensions from 40×40×2 and a length of at least 4...5 times the length of the largest horizontal dimension of the reinforcing bar - rotary lever (the longer the lever, the lower the bending force);

- a rolling bearing unit in which the drive arm will rotate;

- reinstallable stops - steel angles fixed in the drive lever;

- guides - bushings made of tool steel type U8, freely rotating on their axis. To properly guide the workpiece along the base, there should be two of them, but for the simplest work one is enough. It is better to harden the bushing to HRC 50…55;

- wooden handle mounted on a lever.

Installation of such a bender is simple and does not require the use of welding equipment. The base is securely fixed to the workbench, after which the desired size of the corner is selected - a blank for the swing arm. Grooves are milled or drilled into it for installing stops, the locations of which correspond to the dimensions of the required reinforcement (however, a through groove can also be provided). The bearing and guide bushings are attached to the desired location on the base.

Using such a device, you can perform horizontal and vertical bends at arbitrary angles. To increase accuracy, you can provide a manual reinforcement bender with a dimensional scale.

Alternative ways to work with reinforcement

If you are still going to professionally manufacture various metal structures yourself, then it is worth advising you to purchase an inexpensive factory-made machine that will have a lot of useful devices in its design. Typically, such machines operate on an electric drive and have:

- moving part,

- several shafts,

- double-sided stops.

You can see how such a factory machine for bending steel reinforcement works in this video.

But in order to fully understand the physics of the processes taking place and avoid defects in your work with various metal profiles, the following table will be useful to you:

Homemade machine design

The manual machine has a fairly simple design, and to make it yourself, it is enough to refer to a competent drawing of the device. The basis is a metal frame, to which a round pin or an ordinary corner is welded. Another element is the rotating platform, to which the lever, bending and central pins are welded. The distance between the pins is dictated by the maximum diameter of the reinforcement being processed. In order to be able to bend rods Ø6−12 mm on such a manual machine, the legs of the frame are securely fixed to the floor.

All elements of a portable homemade machine are fixed on a massive plate. This, also portable, plate can be secured at the work site with bolted joints or with the help of special pins welded to its lower part. A homemade machine can only be used for bending metal rods whose diameter is no more than 10 mm.

Useful tips

- Do not try to bend the reinforcement with your bare hands by stepping on it. Even thin pins will require at least a vice mounted on a workbench and a hammer. Refusal of devices and a reinforcement machine is fraught with a high risk of injury - there have been cases when such “dared souls” were seriously injured, after which they were taken away by ambulance. Do not bend the reinforcement with jerking movements.

- The process must be smooth: steel, no matter how ductile it is, experiences tension on the outside of the bend angle and compression on the inside. Jerks and bending of rods too quickly violate cold bending technology. The rod heats up, causing additional microcracks at the bend. The jerk can cause the material to weaken and even break.

- Do not file the reinforcement at the bend. In this case, a breakdown is guaranteed. Hot bending also significantly weakens the steel.

- The bend should be smooth, and not polygonal and “wrinkled”, like heating and water pipes that are heated at the bend using gas welding or a blowtorch. Do not try to heat the bendable rod in any way - in a barbecue, on a fire, on a gas burner, by leaning it against a hot heating element on an electric stove, etc. Even pouring boiling water on it is not allowed - the rod must be at the same temperature as the air around it.

- If you are unable to bend the rod, cut and weld both parts at the ends, at a right angle or another. Simply tying such pieces in places of constant shock-tension load (foundation, interfloor ceilings, fence) is unacceptable - the structure will delaminate in a few years, and the structure will be considered unsafe and dangerous for people to live (or work) in it. Do not use a rebar bender that is not designed to handle the required bar thickness. At best, the machine will bend; at worst, the supporting-moving part will break, and you will get injured or fall due to excessive force applied to the machine.

If the machine for fittings is assembled using bolted joints, make sure that the bolts, nuts, and washers are made of high-quality steel, as are the angles, rods, and profiles themselves. Often construction stores and hypermarkets sell fasteners made from cheap alloys in which the steel is diluted with aluminum and other additives that worsen its properties. You often come across low-quality bolts, nuts, washers, and studs. Check them carefully.

It’s better to overpay a little, but buy good bolts made of alloy steel or stainless steel, than to use those made of “plasticine” steel, which easily deforms with any noticeable force.

Such low-quality steel is used, for example, in the manufacture of hex keys and screwdrivers.

- Avoid fasteners made from consumer goods - these are suitable, for example, for fixing roofing iron and plastic sheets, once screwed to beams and resting on them. But such bolts are not suitable where constant impact load is required.

- Do not use a thin-walled profile used for installation of plasterboard floors and siding panels to make a bender. They can’t even bend a 3-mm rod - the corner itself is deformed, and not the bending reinforcement. Even several of these corners, nested one inside the other, will make the structure very problematic; bending with such a dubious device is unacceptable. Use a profile of normal thickness - made of the same steel as the rods themselves. Ideally, there is a piece of rail for the device frame. But this is very rare.

- A well-made reinforcement bender will quickly pay for itself. Its primary purpose is to make a frame for the foundation of a private house and extensions, and a fence as a fence. And if you are also an experienced welder, you will begin to bend fittings to order, as well as weld doors, grilles, and fence sections from it, then such a device will allow you to earn extra money.

Types of equipment

For the modern metal bending process, there are many options for the latest devices. In production, presses are usually used , which can be divided into the following types:

- Rotary, bending metal by moving between special rollers. Suitable for the production of large-sized products in small batches.

- Rotary presses bend the plates using bending beams and two plates. The stationary plate is located at the bottom, and at the top there is a rotating plate. The optimal option for processing sheet metal products with a simple relief and small dimensions.

- Standard pneumatic or hydraulic presses are used for mass or small-scale products made of stainless steel or other metal. Bending is done between the punch and the die. Due to this, even thicker products can be processed. It should be noted that hydraulic presses are used more often than pneumatic ones due to their simpler operation and cost.

Of all the types of equipment described above, the most modern is rotary. It operates automatically, and the worker does not need to calculate the optimal force value in advance.

Rotary presses are also considered automated. Here one sheet is sent to the device, which must be positioned as required by the task. Most often used in small enterprises where they work with metal parts.