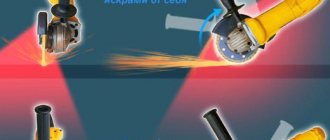

Safety glasses for working with an angle grinder belong to personal protective equipment (PPE) for eyes with increased mechanical strength (marking S according to GOST 12.4.253-2013). This is due to the fact that they must protect the operator’s organs of vision not only from sparks and small particles of the material being processed and abrasive, but also from large fragments of metal and stone, as well as parts of the cutting wheel when it is destroyed during operation. The weight of such damaging elements can reach tens of grams, therefore, in accordance with GOST, protective glasses of this category are tested by the impact of a steel ball weighing at least 43 g. When cutting metal with a grinder, the glasses must also act as a light filter, weakening the brightness of the sheaf of sparks to the required limit. And when working with stone, concrete and ceramics, protect your eyes from fine dust. Using an angle grinder without personal eye protection is strictly prohibited, as is reminded by a special icon on the cutting discs and in the passports of the manufacturers of this tool.

Varieties and characteristics

They are distinguished by the degree of openness and transparency.

The second indicator should be taken into account when work occurs with an object that is too bright or with dangerous radiation. Transparency can be lower than 95% without obstructing visibility. According to the degree of openness, glasses are:

Open - in appearance they resemble regular glasses or sunglasses. A cheap model, sometimes equipped with side corner protection (from the side of the temples), rests on the arms. They have minimal protection against small particles escaping from under the grinder, but do not prevent dust, smoke or harmful fumes from getting into the eyes. As is the case with a regular instance, the open type must be selected individually

It is important that the size and shape fit the wearer perfectly, otherwise the glasses will constantly fall off and get in the way.

Closed is a comprehensive block against large or small particles, dust and chemical fumes. They are attached to the head using a strap or stretchy rubber band. There are models that are a combination of glasses and a mask, which provides complete or maximum possible face protection.

There are series without ventilation, but with a special coating that will prevent the glasses from fogging up. When cutting or grinding hard or particularly hazardous materials, the closed type is preferable, although more expensive.

As for ventilation, it can be direct or indirect.

The first type is the direct presence of through holes or slits in the protective equipment. It is the most economical option and is also suitable for simple types of work no more than several times a month.

The second is valves with built-in filtration of dust, smoke and fine suspended matter. Valves are much safer than direct ventilation and are designed for maximum protection, but increase the cost of the product.

Terms of use

The main danger for the operator lies in the angle grinder mechanism. During operation, the grinder disk rotates and touches the surface being processed. At this moment, the master must hold it suspended with his own hands without the use of additional objects or assistants.

That is why one careless movement can turn into a tragedy, breaking off and creating a sharp jerk of the instrument. This is why beginners are not trusted with professional tools

It is better to start getting acquainted with an angle grinder with a device whose disk diameter is 115-125 mm.

If you properly understand the safety precautions for working with an angle grinder, there is nothing to worry about. Safe work rules:

- During operation, the grinder is held with only two hands. In this case, you need to move it calmly, without pressing or applying force to the device.

- The operator stands firmly and firmly on his feet or knees while cutting or grinding. A comfortable position will help prevent falls and the device slipping out of your hands during sudden jerks.

- The power cable connected to the outlet is located behind the operator's body and should not be placed on the surface being processed. Otherwise, the resulting sparks can burn through it and cause a short circuit.

- It is prohibited to leave the grinder on and leave it. You can move around the room only when the device is turned off.

- If during operation there is a power outage, the power cord of the angle grinder is pulled out of the outlet, and the start button is moved to the off position.

- The diameter of the grinder disk must exceed the thickness of the surface being processed.

Photo of safety glasses

Design features of safety glasses

You can divide all existing safety glasses into several groups. The distribution occurs according to the type of material, design features and coverage area.

By lens material

Several materials are used to create protective glasses lenses. The most common of them are:

- Mineral glass. It has been used since the days of the USSR. The main advantages of the material are its high light transmittance and resistance to light impacts (damage, chips, scratches). The main disadvantage is the fragility of the product and the possibility of injury from chips.

- Organic glass (plexiglass) and plastic. The ability to transmit light of these materials is lower than that of mineral glass, but they are much more flexible. This allows you to withstand fairly strong impacts, and in the event of breakdowns, fragments practically do not appear. But due to a large number of scratches on the surface, the material may become matte, which will make it unsuitable for use. Therefore, the service life of glasses made of organic glass and plastic is not so long. Also, these materials are easily destroyed when exposed to chemicals and at high temperatures (200 degrees).

- Silicone. This material is the most flexible of all listed. It can easily withstand even very powerful blows, but does not cope well with minor damage. Silicone also quickly deteriorates when exposed to high temperatures (sometimes it can withstand up to 300 degrees, but most often it begins to lose its properties at 200). The surface becomes cloudy over time, so the service life is also quite short.

Some expensive models use combination lenses. In them, several materials alternate in layers.

By way of putting on

There are also differences in how glasses are attached to a person’s head. You can put them on yourself in one of two ways:

- Classic with temples. When purchasing this model, the first thing to look at is the possibility of adjusting the arms. It is also necessary to take into account that during active work the glasses may fall or simply move out of place. This can create dangerous situations while performing tasks.

- Sports. Such models are attached with a wide elastic band that goes around the head.

Some modern glasses provide two methods of fastening at the same time. If a special mask is provided for the work, then the fastenings can be supplemented with a small braid passing through the middle of the head.

According to the size of the protected face surface

There is no official classification of glasses on this basis. But they can be divided into several groups conditionally:

- Only the eyes themselves with a small space around them are protected;

- glasses overlap the eyes with part of the adjacent side of the face;

- The entire face is covered with a mask or shield.

There are a huge number of models on sale now. They can either limit or increase the area of protection of the nose, bridge of the nose and other parts of the face.

By size of review

There are also several subtypes of glasses with different viewing angles. They can significantly reduce or expand the operator’s angle of view:

- Additional lenses. These details are located on the temples of a person; they act as an addition to the central part of the lens of the glasses. With their help, it is easy to see objects with “lateral vision”.

- Curved shape. These models do not have additional transparent elements, but thanks to their semicircular shape they are able to expand the viewing angle to the sides.

- Cuts in the arms. These parts are slots in the side. They slightly expand the view, but do not prevent additional dust and foreign objects from entering the eyes.

- Wide transparent temples or frames. This subtype is made entirely of one material. If they are made with a frame, then the eyes receive additional protection from debris from all sides.

- Front view only. This type is equipped with the most modest visibility. It protects the eyes from all sides, but reduces the ability to see from the side.

Safety glasses for working with an angle grinder are divided into several groups. For example, they differ in the color of the lenses, the ability and method of ventilation (to reduce fogging), and tightness. For people with poor vision, it is allowed to use their medical model for protection. In such a situation, remember that models with diopters are not equipped with additional side protection. They cost much more, but are not resistant to damage. Because of this, if you have poor vision, it is recommended to use safety glasses along with lenses, or wear a medical model underneath them.

All about eye protection devices

Something as simple as safety glasses can help you perform any job safely if used correctly. To do this, you need to have information about the device and the materials from which it is made, methods of use, storage and care.

Types and characteristics

Devices that protect when working with an angle grinder, like any glasses for cutting metal, are divided into several categories. One of them is the type of glass designed for eye safety. Currently there are the following types of glasses:

- With transparent glass.

- Tinted.

Darkened eyepieces are used when cutting and grinding materials that generate large sparks.

All types of safety glasses are either closed or open. Open glasses are shaped like sunglasses. This is the most budget option used when cutting and grinding metal in a workshop or room with normal working conditions. The shape and material of such devices are varied. There are both transparent and colored models.

When cutting or any other processing of stone or concrete materials, it is recommended to use closed glasses. They will protect from dust and small crumbs. Modifications of such devices are available depending on the area of application.

Enhanced protection against mechanical damage is provided by glasses with double intensive glazing.

When working with materials that emit harmful radiation, use darkened closed accessories or replaceable light filters.

In gas-filled conditions, sealed protection is needed; in chemical plants, special rubber inserts around the eyepieces are .

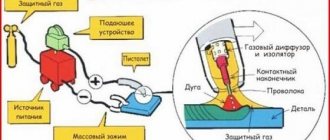

Using the latest technology, the problem of fogging of sealed eye protection devices is being solved. There are two methods of blowing the sub-urinal space: direct, when the air flow moves in one direction, and reverse, when it changes.

Materials and manufacturing technology

As a device that is not very difficult to manufacture, safety glasses consist of two elements. One of them is fastenings to hold the entire structure on the face . It is made in the form of a rim, a fabric ribbon with stretchy inserts, or regular arms that are found in any similar devices. The most practical are silicone or special types of rubber, which have shockproof and protective properties.

How do open funds differ from closed ones?

Safety glasses are divided into:

- open type;

- closed type.

Open - this is the easiest way to protect your eyes when working with the possibility of injury. In appearance they resemble sunscreens. A distinctive feature is the absence of a frame. Most often, they are equipped with large, high-strength glass.

The shape of the glasses may vary, as long as the glass is wide enough to protect your eyes.

A rubberized pad is usually installed on the nose pad, which prevents the glasses from sliding down. For fixation on the head, arms or an elastic band are used, which is attached to the arms.

Open type glasses are different in that there are gaps between the person's face and the glasses into which metal particles or sparks can get caught. Such means do not provide the worker with 100% protection. When working with radiation, open glasses can be equipped with light filters. On sale there are lenses of all shades from yellow to brown, black, gray.

Lenses may have a polarizing coating. This allows the use of a protective accessory when working with ultraviolet, infrared and laser radiation. Open glasses belong to the category of cheap protective equipment.

Closed-type glasses are considered the safest. They are made of double panoramic glass, which is built into a protective mask. The mask ensures that the accessory fits tightly to the face, which allows you to increase the degree of protection when working with an angle grinder.

Closed glasses not only prevent metal particles and sparks from entering the eyes, but also do not create a barrier to dust, smoke, or harmful chemicals.

Closed-type glasses are secured to the head using an elastic band. The elastic band has adjustment elements, which makes the glasses a universal protective device.

Among the variety of models, you can find glasses with direct and indirect ventilation, with the ability to work with different types of radiation. Despite the fact that closed-type glasses are more bulky, have more weight, and can fog up in the absence of ventilation, they are preferable when working. This is due to their increased safety.

Types of construction safety glasses and shields

Construction glasses, according to their protective properties, are divided into three types:

- Reinforced - used for working with wood, stone and tiles. They can withstand even blows.

- With metallized glass - designed to protect against EM radiation, so they are worn when working with electricity.

- With a light filter - used for working in poor lighting, for protection from gas welding and bright sunlight.

According to appearance, they are divided into:

- Open – used to protect against small debris and sawdust. The body of the glasses is made of plastic; they are additionally equipped with a light filter.

- Closed - have built-in ventilation. They fit tightly to the face and protect it from moisture.

- Double - have a double frame in both lenses and body.

- Sealed - protects against volatile substances and hazardous liquids.

Construction screens differ in their areas of use:

- Welding - cover not only the face, but also the head and part of the neck. The viewing window often has a light filter installed, or the glass is simply darkened.

- Manual - intended for one-time use.

- Attached to a helmet – they have special fastenings. They are convenient to use in the wood processing industry.

- Universal – completely cover the face and can be used in any area.

Precautionary measures

The grinder is dangerous even for a professional. Therefore, when turning it on, adhere to the following safety measures:

- Do not approach the tool or use it without protective glasses and special clothing. A jacket or shirt should cover your hands from sparks flying from under the tool.

- Before the disk comes into contact with the workpiece, it is checked for functionality. To do this, you need to turn on the grinder at idle speed with the disc and wait a couple of minutes.

- Removing the protective casing from the angle grinder is prohibited.

- If the material is being cut in a horizontal position, the operator and his assistant stand to the side of the device.

- You also cannot put additional load on the tool; it must function under its own weight. Otherwise, the equipment will begin to deform and the device will jerk.

- After working for a long time, it is necessary to take breaks. Prolonged load leads not only to overheating of the tool, but also to operator fatigue and hand shaking.

- Before starting work, check whether the workpiece is securely fixed to the surface.

- Sanding the surface with the sides of the cutting disc is prohibited. For this purpose, only special abrasive attachments are used.

- Only a master and an assistant can be in close proximity to the tool. Other people in the room should move away to a safe distance.

- The radius of the cutting disc should be equal to 1/6 of the thickness of the material being processed.

Chips, cracks, or fragments of the disk loosen the device and cause it to slip out of the master’s hands. It is because of this that before starting the grinder, all consumables are checked for defects. It must be remembered that damage to disks occurs not only during work; sometimes it occurs when transporting tools. Sometimes people accidentally step on a tool without caring about the consequences.

Even with careful handling of the grinder and thorough inspection, operators miss external defects. If this happens, safety precautions warn that thick gloves, goggles or a mask can save you from injury.

The grinder will become a useful and indispensable tool during construction work or when performing repairs. With its help, it is easy to grind or cut off any surface with minimal physical and time costs. A little experience and practical advice from a specialist is enough to successfully work with the device. And following safety precautions will help you avoid serious injuries while performing tasks.

Common defensive ammunition

Various personal protective equipment are mandatory when using power tools. This is primarily due to the presence of chips, sparks and other elements that are formed during the work process and can cause harm to the human body. To avoid various types of injuries, people have developed simple and effective protective equipment that helps make the work process more comfortable and safer.

Eye protection glasses

This is a mandatory element of equipment when working with an angle grinder. It is advisable to opt for closed-type glasses that tightly fit the shape of the face and prevent foreign elements from getting into the eyes. This is due to the fact that the flight path of metal shavings, sparks and scale is unpredictable, and they can get under a protective mask or glasses. Therefore, before purchasing, it is advisable to always try on and adjust the product to suit yourself. The material used in the manufacture of the protective product also plays an important role.

It is important that the plastic has a high degree of strength and can withstand mechanical stress.

Masks

These are more reliable protective equipment than glasses, as they can cover not only the eyes, but the entire face. Unfortunately, in order to save money, some manufacturers use materials that are not of the highest quality, which affects the level of protection. Therefore, it is worth choosing masks from well-known manufacturers that look quite durable and have a protective mesh. This additional element is primarily intended to protect a person’s face when working with an angle grinder, since the cutting wheel can burst and fly into the eyes at great speed, and the mesh can stop it.

Mittens and gloves

It is impossible not to mention these most common, but no less important protective elements. When using an angle grinder, your hands are located in close proximity to the rotating disk and therefore require high-quality protection. Conventional gloves used in construction are not able to cope with the given protective task in all situations, since they are highly flammable and therefore quickly burn out from sparks, leaving burns on the body. When working with an angle grinder, it is better to use gloves made from rough leather or products with a rubberized base.

Also, if you have welding gaiters, which are made using durable suede, you can use them when working with power tools. Due to the high base of this type of gloves, they are able to protect not only the fingers and palms, but also the forearms.

Which is better: glasses or a mask?

In addition to glasses, when working with an angle grinder, protective masks (transparent face shields) are used, which protect not only the eyes, but the entire area of the face to the chin and ears. This type of personal vision protection has a number of undeniable advantages, among which the main thing is complete protection of the face from fast-flying particles. This is especially important when working with an angle grinder in confined spaces, when particles of metal and abrasive ricochet and hit your face from different directions. Another positive feature of face shields is the almost complete absence of optical distortion, which is inherent to one degree or another in all safety glasses. Therefore, when working with an angle grinder for a long time, many people prefer this type of protection. The disadvantages, or rather limitations, of using face shields include the free penetration of dust and fumes under them. Therefore, they cannot be used when using a grinder to process stone, concrete or ceramics. In addition, face shields are much more massive and heavier than glasses and, with the same quality of optical material, are more expensive. The debate about which of these AIS is better and more convenient does not make sense, since each of them is used for certain types of work and specific situations. Moreover, in some cases, angle grinder operators use them together, and a number of manufacturers even produce special face shields that are attached to closed glasses (see photo below).

How medical devices work

Medical safety glasses are devices that are designed to protect the eyes from particulate matter, chemicals, or harmful radiation during medical procedures.

They found the greatest applicability among surgeons and dentists.

During surgery or treatment, glasses protect against:

- splashes of biological fluids, used medications, chemical compounds;

- flying fragments;

- dust and harmful cleaning compounds and their fumes during the treatment of premises.

Medical protective devices with light filters are used when processing metal, ceramics or plastic in the manufacture of dental crowns or prostheses, in the case of laser procedures.

During manufacturing, medical glasses are immersed in a special composition that reliably protects the inner surface of the glass from fogging. Models of medical glasses are smaller in size and lighter in shape.

They are divided by type into closed and open in the form of a mask. Helioprotective glasses are also available. They have a light filter that does not allow the blue part of the light spectrum to pass through. The glasses of these glasses are made in orange or brown.

Thanks to their universal shape, medical glasses can be worn over regular glasses to correct vision. This combination does not cause discomfort.

https://www.youtube.com/embed

https://medglaza.ru/voprosy/ochki/raboty-bolgarkoj.html

How do safety glasses work?

The means under consideration include the main and fastening parts. The main part is presented in the form of protective glasses and fastenings for them, and the fastening part consists of arms or straps. Glass is the base that provides reliable protection for the eyes. Fastening is mandatory, since the ease of use of protective equipment depends on the quality of fastening.

Additionally, safety glasses may include:

- Ventilation holes

- Arm Length Adjusters

- Fasteners of different types of fastening

- Gaskets made of rubber and fabric base

What is protective glass for such products made from? Various materials are used for this, namely:

- Glass with impact-resistant properties. The use of glass in the product provides more advantages, since visibility reaches 100%

- Polymer materials, since glasses made of polymers are popular because they are cheap, but any scratches on the surface distort visibility

- Plastic, such products are popular in cases where there is a risk of not only sparks and small particles getting into the eyes, but also shavings or splinters

- Silicone is a material that began to be used not so long ago for the manufacture of safety glasses. Its characteristics can be compared to plastic.

This is interesting! Plastic products will help protect your eyes from metal particles, since polymers or glass tend to be damaged. If there is a possibility of chips or large fragments entering your eyes, it is recommended to use safety glasses with a metal frame or a mask.

If a person does not wear glasses when working with an angle grinder, then he jeopardizes not only his vision, but also his own life. In addition, when working with an angle grinder, it is not recommended to use ordinary glasses with a magnifying glass. They do not protect against sparks and small particles, and the glass on them can crack under mechanical stress.

Tips for choosing the right glasses for working with an angle grinder

When choosing safety glasses for working with an angle grinder, special attention is paid to certain details. These include:

Case material. To protect your eyes, choose a model that can reliably protect your vision. The presence of a thin frame with glass does not guarantee the safety of the operator.

Additional protection against ultraviolet rays. If you work with an angle grinder often in the fresh air, it requires the presence of sunlight. To protect your eyes from bright rays, it is better to buy protection with a special coating against ultraviolet radiation. “Chameleon” models have become widespread among craftsmen.

Ventilation

If a closed model is used when working with an angle grinder, pay attention to ventilation. When there are no holes on the surface, you have to often remove the protection and wipe off condensation.

Price

You can't skimp on quality. If, when purchasing, it is clear to the naked eye that a cheap model will quickly deteriorate, it is better to buy a more expensive one.

Convenience. Immediately upon purchase, the model is tried on. The frame should not be too tight or restrict movement, or fall off the ears. Otherwise, you will have to be frequently distracted while working, and this can lead to serious injuries.

Review of the best models and manufacturers of glasses and masks

There are several dozen brands on the Russian market that offer personal protective equipment for the eyes, including glasses for working with angle grinders. But only some of them are directly manufacturers of personal protective equipment, and the rest are international and Russian brands owned by manufacturers and sellers of power tools, gardening and power equipment. In the first group, the most famous are the Russian JSC Suksun Optical-Mechanical Plant (trademark ROSOMZ) and two very well-known international companies: Uvex and 3M. In user reviews and reviews of safety glasses designed for working with angle grinders, models of power tool brands such as Zubr, Sturm, Styer and Fit, as well as ROSOMZ products, are noted among the lower and middle price ranges. Closed models with indirect ventilation ROSOMZ ZN11 Panorama, Zubr 110230, Sturm 8050-05-02 and Stayer 2-110291 are popular among grinder users. In the upper price range of personal eye protection, the undisputed leadership belongs to 3M and Uvex, and the latter’s products are also produced under such well-known brands as Makita, Hilti, Husqvarna and others. Here, in terms of price-quality ratio, owners of grinders distinguish the closed models 3M 2890, Uvex Ultravision 9301714, as well as the Russian ROSOMZ Surgut.

Care and storage rules

Inexpensive glasses, even those made of the most durable plastic, sooner or later wear out and become unusable. Before each new use, carefully inspect the glasses in order to replace them with new ones if there are deep cracks, abrasions, and the headband may burst or stretch at the wrong moment.

Be sure to wipe your glasses with a damp cloth to remove layers of dust and dirt. In hardware stores you can purchase packages of cloth soaked in a special solution for disinfecting glasses.

They should be stored in the case provided for this purpose. Glasses made of strong material with increased impact resistance will last the longest.

They are not subject to mechanical damage, do not ignite and will not melt from random sparks and hot particles. You can clean them calmly, without fear of erasing the protective coatings or leaving scratches. It is better to give preference to closed glasses with a comfortable lining and an adjustable strap.