Purpose of taps

Taps are used only for cutting internal threads. Completely different tools are responsible for external threads.

- The tool is capable of making new threads in completely different holes or updating an existing one.

- Work can be carried out with different metals, such as brass, copper, similar metals and plastic.

Typically, a set containing three taps is used to make threads. Some cases require up to five taps.

To use it, you need a special tool - a tap holder. The tap fixed in it is inserted into the hole and turned in the desired direction.

Taps - broaches

To obtain large-profile threads in metal products, use a broach tap. It is used to process complex through or trapezoidal holes. Broaches can only be used in a lathe. The thread is cut in one pass along the hole. This tap differs from other types in its more precise design and rigidity. It works in tension rather than compression like conventional threading tools. Due to the broaching function, the thickness of the cut is reduced, and the length of the cutting part is increased.

Design and characteristics of taps

The tap is a very simple tool, its design consists of two main parts. The first part is the tail of the tap; it is this part of the object that is fixed in the tap holder or on the machine.

The second part is the main one; there is an external thread on it, which in turn consists of two parts:

- Cutting element. This part of the thread is designed to form thread turns in the hole.

- Calibration element. The second element is necessary for cleaning the newly cut holes and calibrating them.

On the sides of the tap there are special elements called feathers. It is thanks to them that the thread is formed.

Threading [ edit | edit code]

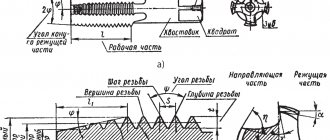

The tap is attached with the tail part to the driver, the working part is inserted into the hole in which, when turning the driver, a thread is cut in a reciprocating motion. The working part of the tap has cutting and calibrating parts. To avoid friction on the workpiece, the rear surface is backed (non-round). The thread profile of the tap must match the profile of the thread being cut.

When cutting threads, sets of two or three taps (rough, medium and finishing), differing in size and profile accuracy, are often used; on viscous materials (for example titanium alloys), sets of five taps are used. To perform most household plumbing work, two taps are enough; these are the sets that are sold in retail trade.

There are taps for blind and through holes.

Taps are made of carbide or high-speed steel.

Taps can be used on lathes, drills and machining centers (machine taps), as well as for manual threading. A machine tap differs from a manual tap in the shape of the lead. The tap is secured on the machine in a special chuck (chuck with axial compensation) or a regular collet chuck with a collet for taps. Also recently, as an alternative to axial compensated chucks, compensated collets have begun to appear, which can be used on a conventional collet chuck.

To obtain internal threads by plastic deformation (rolling), chipless taps (rollers) are used. Their main difference from cutting taps is the absence of chip flutes.

There are also nut taps used to make nuts. This type of tap has a longer shank and lead-in (calibrating) cutting part.

When cutting threads, the tap is pre-lubricated with grease, for example, grease. Periodically turn the tap in the opposite direction to break off the resulting chips. If you use a tap out of order (for example, finishing instead of rough), it can easily break.

A tap is a tool for forming a thread profile in a hole. Taps have a working part, a neck and a shank. The working part of the tap is intended for mechanical cutting and consists of a cutting part, cutting teeth and calibrating teeth. The tool shank is designed to secure the tool on machines in special thread-cutting chucks, or during metalworking work, the square shank of the tap is installed in a tap holder or driver.

rice. 1 – taps with a helical groove for blind holes

rice. 2 — tap holder

Types of taps

Taps are divided according to the type of work performed

Hand taps are used in sets of 2-3 pieces. Each tap is marked No. 1,2,3. Taps No. 1 have a large length of the intake part and a reduced size in terms of the average diameter of the thread; it is also called a rough tap. Tap No. 2 or No. 3 has a shorter taper length (approximately = 2-3 thread pitches), this allows you to process blind holes as close to the bottom of the hole as possible, and it also has a final thread profile, such taps are called finishing taps.

Taps are manufactured according to different standards

Russian standards

Machine-hand taps for metric, inch, pipe threads - GOST 3266-81.

rice. 3 – tap with reinforced shank

The reinforced shank increases the rigidity of the tool and, as a result, durability. Used on threads up to M10 (inclusive) main pitch.

rice. 4 – tap with neck

Used when cutting shallow threaded holes. They are a cheaper alternative to taps with a through shank manufactured according to DIN.

rice. 5 – tap with a through shank

The through shank allows you to cut threads longer than the cutting part of the tap.

Machine taps for metric threads - GOST 8859-74.

rice. 6 – machine tap

Nut taps for metric threads - GOST 1604-71

rice. 7 – nut tap

Nut taps with a curved shank for metric threads - GOST 6951-71.

rice. 8 – nut tap with curved shank

Foreign standards

Complete hand taps for metric threads – DIN 352

Machine taps with reinforced shank for metric threads – DIN 371

Machine taps with a through shank for metric threads – DIN 376, DIN 374

Complete hand taps for small metric threads – DIN 2181

Nut taps for metric threads – DIN 357

Machine-hand taps for metric threads – ISO 529

Hand taps for pipe threads – DIN 5157

Machine taps for pipe threads – DIN 5156

Materials

Various materials are used to produce taps, including:

- Alloy steel;

- Tool steel;

- High speed steel.

The most common and optimal option is considered to be high-speed steel. It has many advantages over others:

- High service life;

- Resistance to temperature changes;

- High quality of work performed;

- Ability to work at high speed;

- High strength material.

To work with some materials, special taps with an additional coating are made. This solution increases the service life and efficiency of the tool.

Nut taps

Nut-type tools are designed for thread cutting in nuts of different diameters. The design of the nut tap is such that the tool does not need to be turned out at the end of the nut hole machining process. Nut accessories can be with different shanks: curved and elongated. With curved ones - used in working with automatic nut-tapping machines. The shank of a nut tap is, in any case, longer than that of other types; this is necessary in order to string nuts onto it as threads are cut into them. This increases speed and productivity.

Types of taps

There are a large number of taps that are used to form a wide variety of threaded holes. All of them are divided according to different parameters. The first division of the equipment is its thread type:

- Metric;

- Inch;

- Pipe.

Taps by thread type differ in the profile angle and the number of turns of the future thread. The differences also lie in the slope of the profile, which is necessary for greater reliability of the threaded connection.

In addition, taps can differ in the type of groove:

- Straight groove;

- Helical groove.

Products with screw groove type are divided into left spiral and right spiral. They are designed to create different holes. The first type is used to create threads in blind holes, the second in through holes.

Taps are divided into single-approach and multi-approach. Depending on the type, they are designed to perform work in one or several approaches. For multi-approach products, it is normal to have a set of several taps, each of which must be used to correctly form the thread.

The main parameter for dividing tags into types is purpose. Tools that differ in their purpose:

- Locksmith. The simplest variation of a tap that can be used without special equipment.

- Machine. The difference from a bench tap lies in the shape of the product and the method of its use. Operation is only possible with a special machine.

- Machine-manual. A universal tool that can be used manually and on a special machine.

- Conical. Due to their special shape, such taps are used to form conical threads. Typically used on special machines.

- Cylindrical. An ordinary tap used to form threads in blind holes.

- Nut. It differs from all other models in its elongated tail and the ability to thread several nuts at once.

- Spot. A one-step type of tool that is used to create threads in dies.

- Uterine. The tap is used as an addition to the die tap. It is designed for stripping formed turns.

- Trapezoidal. One-step tool, resistant to high loads. It is used to create trapezoidal shaped threaded holes.

- Grooveless. Taps characterized by a minimum number of grooves in their structure.

- Screw. Such products are designed for quick processing of dead-end holes.

- Combined. Tools that can perform multiple functions at once. For example, a tap-drill.

- Stepped. Ordinary equipment consisting of two parts. Cutting and calibrating.

- Bells. Used to form large diameter threads.

- Chess. Taps that are designed to reduce friction.

- Broach tap. Such equipment is used when it is necessary to form threads in through holes. Slaves are carried out with the machine.

- Rolling tap. Due to the nature of working with the tool, there is no chips or dust.

- Hollow. Taps that are necessary for creating threads in difficult working conditions.

- Candlesticks. Designed for forming threads in spark plug wells of internal combustion engines.

- Fishing Common in the oil and gas industry.

Thread classification

- Metric. The most common fastening thread. The diameter of the parts is measured in mm.

- Pipe. Used in the installation of pipelines and shut-off and control valves (mixers, taps, valves). Diameter is measured in inches and fractions of an inch, which is why it is also called inch.

- Threads on the outer surface of parts: bolts, studs, pipes are called external, and nuts, blind sockets and couplings are called internal.

- The direction of rotation distinguishes between left and right.

- By the number of passes - single and multi-pass.

- The cross-section can be triangular, rectangular, trapezoidal, etc.

- Can be straight (cylindrical) or conical.

Cost of taps

Prices for taps vary from several hundred to several thousand rubles. All this depends on the materials from which the instrument is made and on its type.

Thus, simple taps, such as metalworking, stepped or screw products, are relatively inexpensive, while the cost of fishing taps starts from four thousand rubles.

To form a high-quality and reliable threaded hole, it is important to choose the right tool. The choice depends on what materials will be used and the characteristics of the required thread.

Application

Threading tools are divided into types according to design features and application:

- • manual, where the teeth are arranged in a circle. Used in metalwork and manual cutting;

- • nut, for through holes on nuts. With an extended or curved shank;

- • machine, for creating blind holes by machine. Processing takes place on lathes;

- • combined, it is possible to use both manual and machine methods of applying threads to the part.

The tool allows you to apply all types of threads - metric, inch, trapezoidal.

Photos of taps (for thread cutting)

What materials are taps made from?

Metal-cutting tool dies are made from high-quality steel of different grades: tool, high-speed, alloy. Modern production technology allows taps to be made from carbide steel and powder steel; in the latter case, the tool is produced by sintering powders. Taps made of carbide alloys are of higher quality, as they are resistant to high temperatures, wear-resistant and can work for a long time at high speeds, which allows processing a large number of metal products. Tools made from steel powders also have their advantage - high strength due to the lower hardness of the tool.

Best Advanced Tap and Die Sets

Professional kits include over 50 tools. They are distinguished by a wide range of applications and are designed to carry out the most precise and accurate work.

Matrix 773110

4.9

★★★★★

editorial assessment

97%

buyers recommend this product

A special case is provided for storing and carrying all the tools included in the set. It is equipped with holders and a strong latch, eliminating the risk of accidental opening and loss of contents.

The number of items is 110, the weight of the set reaches 7.6 kg. All devices are made of hardened alloy steel, resistant to heavy loads and corrosion. This guarantees long-term preservation of their quality when used in difficult conditions.

Advantages:

- wide range of equipment;

- ease of storage;

- durable materials that are corrosion resistant;

- durability.

Flaws:

- very heavy weight.

A set of Matrix taps and dies is suitable for working with non-ferrous metals and steels.

BISON 28119-H110 z01

4.9

★★★★★

editorial assessment

96%

buyers recommend this product

The main material for making tools is carbon steel of increased hardness. This guarantees their resistance to mechanical loads and a long working life.

A set of 110 pieces weighs 9.7 kg. The tap holder is equipped with a special mechanism that securely fixes the shanks, and a locking screw is used to secure the dies. The presence of a clamping chuck makes it easier to make threads in hard-to-reach places.

Advantages:

- durable manufacturing materials;

- ease of carrying;

- reliable fixation of tools;

- durability.

Flaws:

- large dimensions;

- heavy.

BISON 28119-H110 is suitable for professional work in the most difficult conditions.

JTC Auto Tools JTC-5214

4.8

★★★★★

editorial assessment

90%

buyers recommend this product

The set comes in an ergonomic case with a comfortable handle that makes transportation easy. Deep holders allow you to secure tools and reduce the likelihood of losing them. The presence of latches prevents accidental opening of the lid.

The dimensions of the package in the package are 380x315x85 millimeters, the full case weighs 6.2 kg. All main and auxiliary devices are made of high-quality alloy steel of increased strength, which guarantees their reliability and durability.

Advantages:

- ease of carrying;

- durable materials;

- quick access to tools;

- long service life.

Flaws:

- high price.

JTC Auto Tools JTC-5214 is suitable for quickly producing threads of various sizes.

Eureka ER-00603

4.7

★★★★★

editorial assessment

87%

buyers recommend this product

The main devices of the Eureka ER set are made of durable steel, which ensures high-quality processing of parts and a long service life of the working elements themselves. The availability of tools for creating both metric and inch threads expands the scope of application of the kit.

Dimensions - 375x265x35 millimeters, number of items - 60. In addition to taps and dies, the set includes holders, a screwdriver and a pitch meter. Weight of only 2.8 kg will not cause any inconvenience during transportation.

Advantages:

- high strength and durability of the tool;

- light weight;

- convenient to carry.

Flaws:

- instability to corrosion.

The Eureka ER-00603 kit is recommended for working with various metals. An excellent choice for home and professional use.

Best Budget Tap and Die Sets

The kits presented in the category cost about 1000 rubles. They are compact, easy to store and transport, but include a small number of tools.

Hammer Flex 601-039

4.9

★★★★★

editorial assessment

94%

buyers recommend this product

All tools included in the set are individually marked for easy selection of the right sizes. Parts made using these dies and taps are fully compatible and do not require modification.

The number of items is 12, the weight of the set is 545 g. All devices are stored in a plastic box with a transparent lid and deep trays. The presence of a special eye makes it possible to hang it on a nail or hook and always keep it at hand.

Advantages:

- marking of instruments;

- ease of storage;

- light weight;

- durable steel;

- long service life.

Flaws:

- fragile case.

Hammer Flex is good for regular use in a professional workshop.

Stayer 28012-H20

4.8

★★★★★

editorial assessment

88%

buyers recommend this product

The set comes in a convenient plastic box with inserts. It facilitates the storage and transportation of devices and can be fixed at the workplace thanks to a special hole. Number of items in the set - 20, total weight 720 g.

The alloy steel used for the production of tools has improved contact strength and wear resistance. And the finished carving is of high quality and does not require further processing.

Advantages:

- compact and easy to carry;

- high quality carving;

- high strength steel;

- low cost.

Flaws:

- holders require preliminary adjustment.

Stayer 28012-H20 is suitable for occasional use - an inexpensive kit for the home DIYer.

Skrab 33860

4.7

★★★★★

editorial assessment

86%

buyers recommend this product

This 10-piece set is lightweight (300 grams) and easy to use. The holders included in the kit provide reliable fixation of tools and comfort during prolonged work in any position.

The main material for the manufacture of taps and dies is tool steel of increased hardness. Resistance to high mechanical loads guarantees a long service life of the devices.

Advantages:

- strong and durable materials;

- reliable fixation of the tool;

- small dimensions;

- low price.

Flaws:

- no carrying case.

The Skrab set is designed for working with soft metals at home.

Fit 70780

4.6

★★★★★

editorial assessment

84%

buyers recommend this product

The tools included in the Fit kit are made of durable tool steel and are not subject to rapid wear and deformation. The compact and lightweight case helps prevent contents from being lost during transportation and simplifies storage.

The dimensions of the case are 245x125x20 millimeters, the number of items in it is 20. Along with the taps and dies, the necessary holders are supplied that reliably fix the devices during operation.

Advantages:

- small dimensions;

- light boxing;

- durable materials.

Flaws:

- the metal is not resistant to corrosion.

The Fit 70780 kit is designed to work with non-ferrous and soft metals. It will be useful during minor repairs and pipe installation.

READ ALSO

12 best engravers