High-quality forged products always cause some kind of childish delight. Flowers with leaves on the stair railing look like real plants that have suddenly turned into metal. They seem to take us back to a fairy tale, to the world of medieval castles and knights. Artistic forging in the interior of an apartment or house is now a rare phenomenon due to its high cost, but it is worth it. If you are thinking about purchasing forged products, learn more about the features of forging.

The Slavs have always been famous for their blacksmiths, but forging was rarely used to decorate their homes. Weapons and armor were increasingly decorated. But European castles began to be decorated with forged parts since ancient times. When, thanks to Peter I, Europe and Russia finally crossed paths, the interior and exterior of the Russian house were decorated with some foreign innovations. Now there are many ways to use artistic forging, from candlesticks to a forged gazebo.

Types of artistic forging:

1. Depending on the mechanization of labor:

- manual or free;

- stamped (for individual repeating elements, such as leaves).

2. Depending on the metal processing method:

- hot (this is what interior items do). The metal is first heated, and then the master performs the necessary operations with the ductile metal;

- cold (suitable for soft alloys and metals). The blacksmith first gives the required shape to the soft metal, and then fires and hardens it.

Hot steel forging technology

Forging begins with heating the workpiece in a muffle furnace or forge, then the hot metal is sprinkled with forge flux. When processing steel, the following operations are performed:

- according to the required dimensions, the red-hot semi-finished product is divided into parts;

- cutting is carried out - external processing of the surface of the workpiece;

- excess fragments are cut off from the metal, resulting in a rough version of the product;

- drawing is performed, after which the workpiece becomes longer and narrower;

- using special tools, holes of various shapes are punched;

- if required, the workpiece is given the desired bend using a template (or without it);

- at the final stage, after additional operations, finishing is performed.

During hot forging, upsetting, upsetting, broaching, rolling, rolling, piercing and straightening are performed. As sedimentation work progresses, the workpiece increases in cross-section and decreases in height. When planting, a thickening is made on the surface. In this case, the length of the semi-finished product is also reduced. Broaching is another blacksmithing technique in which the workpiece is lengthened and thinner.

During rolling, the heated material takes on a cylindrical shape: during hot forging of this type, the workpiece is wrapped around its axis. Rolling involves processing a ring-shaped semi-finished product, which changes its internal and external diameters during processing. As it accelerates, the metal object becomes wider.

Attention: Firmware is an operation that produces a through hole using a punch.

Art casting and art forging - what is the difference?

Casting is also often used to decorate apartments, houses and streets. It is distinguished by its massiveness, the use of a casting mold, and more rounded shapes. Large products are made of cast iron with additives, and small ones are made of bronze and tin. Forging is unique (especially completely manual), as well as greater strength and delicacy. The main materials for the production of forged products: various grades of ductile steel, as well as copper, bronze, aluminum, brass, titanium and their alloys. Non-ferrous metals are usually used for colored decorative inserts. By the way, they now produce products from polymers that imitate forged products.

Artist Statement

Ancient methods of hand forging metal are an integral part of the sculptural structures created by the master. The forging design is intimate and delicate, because at the moment of creation the master is inspired by nature, animals, birds, man and his experiences. The artist works on the implementation of various large-scale projects: from small interior items to large gates and fences. The commissioning process allows the customer to take part in the development of the project, offer their ideas and developments. The client may need help identifying a location or space, and may need to build a barrier or expand the space. All these aspects influence the design and finishing of the project. The development of ideas is carried out in several stages:

- working on sketches and layouts;

- drawing up a written contract outlining the requirements;

- cost determination;

- technical description of installation and maintenance;

Artistic forging and interior style

Forged products must exactly match the chosen interior style. At the same time, they are able to naturally fit into almost any interior, from classic to modern. Only the appearance of the lace differs:

- for a classic style, a pattern with simple symmetrical shapes would be appropriate;

- for Gothic - complex and symmetrical;

- for Romanesque - curlicues emanating from a single center;

- for the Renaissance - garlands of fruits, berries and leaves, spirals reminiscent of the tendrils of a grapevine;

- for Baroque - elaborate and complex;

- for Rococo - thin weaves with airy and asymmetrical patterns;

- for empire style - simple and clear lines;

- for Byzantine - an ornament of symmetrically and geometrically clearly arranged plant patterns;

- for Russian - floral patterns with flowers in the middle;

- for modern - asymmetrical, whimsical;

- for minimalism - strict geometric patterns;

- for high-tech - straight lines without curls, only clear geometry.

Do-it-yourself hot metal forging

To forge metal in a home workshop, you need to meet certain conditions. It is required to make a forge. It is necessary to learn how to select the correct forging temperature. It is necessary to select the most suitable fuel for heating the workpieces. During the forging process, it is important to avoid mistakes that cannot be corrected.

How to make a forge for forging at home

Furnaces can be solid, liquid and gas fuel, stationary and portable, with a closed or open hearth. The gas-powered design has many more advantages than its analogues. Among the advantages: economical fuel consumption, high efficiency, lack of sulfur accumulation.

A gas forge, consisting of a furnace and a burner, is made with your own hands in the following order:

- for the design of the equipment, a metal container is sought: a bucket or barrel can be used as it;

- a hole is made on the side for the gas supply system, for which an electric drill with a crown is used;

- a burner is assembled from couplings and pieces of pipes;

- holes are drilled from the bottom of the container for the forge legs: the stands are fastened with nuts and long bolts;

- the lining of the hearth is created from alabaster backfill with the addition of sand and water: a ceramic pipe is used to construct the internal walls;

- After making the lining, a hole is made for the fuel supply.

Fire bricks are also suitable for creating a gas furnace. It is held together using clay. A hole is drilled in the constructed structure for the existing gas burner.

Important: Propane fuel sold in cylinders will be sufficient to heat workpieces made from most steel grades to the required temperature.

Selection of temperature for forging steel

When the metal is heated correctly, a forging temperature is achieved, which is evenly distributed along the length and thickness, and integrity is maintained and a minimal layer of scale is formed. These conditions are met if the required parameters of the limit, duration and heating rate of the workpiece are achieved.

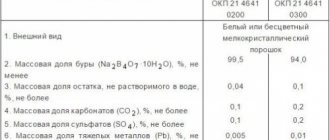

Table 3. Forging temperature ranges for steels and non-ferrous alloys

It is impossible to overheat the workpieces, because cracks and torn areas will form on the forging. The speed is determined by the thermal conductivity of the metal, which depends on the chemical composition and thickness of the processed semi-finished product. The duration of incandescence is influenced by the heating rate and the type of muffle furnace or hearth.

Fuel for forging metal at home

Gaseous fuel, quickly mixing with air, burns completely, as a result the metal does not actually oxidize when heated. But when using it, you need to have a closed forge and follow safety rules. Liquid fuel is more often used to kindle metal heating equipment. It is rarely used fully, since it requires the use of expensive devices. Solid fuel, if it is of high quality, creates short flames and sinteres well.

Attention: The most popular among home craftsmen are coke, charcoal and coal.

Home forges typically use charcoal. This fuel is of high quality, inexpensive, but burns quickly, so a lot of it is required. Coal in small grains raises the temperature well, but during forging you need to constantly monitor the cleanliness of the fire and the height of the flame. The cost of coke is higher, but its consumption is 4 times less. In addition, when this fuel burns with high efficiency, there is no soot.

Mistakes when forging at home

If you exceed the initial temperature (tn) of heating the workpiece, its plasticity will decrease significantly, in addition, the structure of the metal will change: it will become coarse-grained. If the temperature continues to be raised, the semi-finished product will burn out, and this error will no longer be corrected.

Rice. Method for determining steel grade by spark

If the workpiece is not heated enough, cracks will appear in it. Therefore, when hot forging at home, it is necessary to strictly observe the temperature regime: you cannot cross the limits of the interval from tn to tk. You must first, knowing the grade of metal, check Table 3. If the material was not purchased in a store, but was purchased at a scrap metal delivery point, it is recommended to use Table 3. 1 and the above figure, determine the grade of material based on the color and appearance of the spark.

Where can artistic forging be used?

Outside the house:

window and balcony grilles, fences, lanterns, bridge railings, gazebo walls, benches, flower trellises, awnings, gates, wickets, barbecues.

Furniture in the interior

Forged furniture is always the center of the interior, and all other items only shade and complement it. It is good for both spacious rooms and small apartments. Only in the latter case there should be as little furniture as possible so that nothing obscures the openwork metal. You can order forged tables and chairs, stools and banquettes, coffee tables, beds with openwork headboards, cabinet doors and furniture fittings.

Functional interior items

Newspaper boxes, fireplace grates and fireplace accessories; stands for umbrellas, newspapers, flowers, clothes; chandeliers, sconces; mirror frames; watch; stair railings; interior doors and door handles; screens and partitions.

Decorative elements

wall panels, candlesticks, vases, etc.

Yes, perhaps forged products are very expensive, but this is because their production takes a lot of mental and physical strength of the blacksmith, not to mention the cost of materials. However, artistic forging in the interior of an apartment looks so easy, elegant and beautiful that everyone should at least think about such a purchase.

What is the difference between cold forging and hot forging?

Cold forging is a modern method of metal deformation. Products produced in this way are predominantly utilitarian in nature - there can be no talk of exclusivity here. The reason is the peculiarities of the technology: the blanks are cut out on machines, then bent on machines without heating, and then joined by welding. It takes significantly less time to create cold-forged products than to produce hot-forged compositions. Naturally, they are relatively cheap.

Hot forging is an art form that involves the manual production of exclusive, decorative and functional products. During the work, the metal is heated to the highest temperature, after which the workpieces are given the desired shape using hand tools and artistic techniques. Finally, the finished product is immersed in cold water to harden the material. Hot forging products are relatively expensive, since the process of labor-intensive work requires high professionalism of a master blacksmith.

Selection of forged products to suit the interior style

Products for different styles:

- Provence. It is better to decorate walls and furniture with floral designs and individual metal branches.

- Scandinavian style. The geometry should not have smooth corners or smooth bends. All decorative elements must be strict, consisting of straight lines connected at sharp angles.

- Rococo. The lines should be refined, gradually moving towards massive objects.

- East style. Includes ornate intertwining lines, leaves, branches. There should be no sharp corners or a large number of straight lines.

- Loft. Sharpness should prevail in the design. It is necessary to make more sharp corners, objects, and rough-shaped decorations.

Attention should also be paid to the color scheme. For example, for the Scandinavian style and loft, dark shades and natural metallic colors are suitable.

Rococo style design (Photo: Instagram / n_hramcova)

Product care

There are no special rules for caring for forged products. It is enough to regularly clean metal surfaces from dirt with a dry or damp cloth. For products located outside, it is recommended to renew the anti-corrosion coating every month, for items located inside the house - every 3 months.

Forged elements are suitable for decorating different interior styles. They are made to order by blacksmith shops and large metalworking enterprises. If you want to save money, you can forge a decorative element yourself. To do this, you need to study forging technology (hot or cold), learn how to work with different types of metals.