Homemade winch from a starter: drawings of an electric winch, photo of making a homemade product with your own hands.

To make a homemade winch, the author used a starter from a VAZ 21015. The engine from a car starter is designed for short-term operation and quickly overheats, but is quite suitable for making an electric winch.

We will also need a reduction gearbox from a hammer drill; you can find a gearbox at a flea market; in this homemade product, the author took a gearbox from an old Soviet-made drill with a gear ratio of 1 x 20.

The motor shaft needs to be connected to the gearbox shaft; this can be done using an adapter coupling and cotter pins, or simply weld them together.

Assembled into a single body.

Now we will make a drum for the winch from a piece of metal tube and sheet metal 3 mm thick.

A bolt is fixed in the pipe for fastening the cable.

We cut out two circles from metal with a hole in the middle and weld them to the pipe.

The gear and shaft need to be welded to the drum. In this homemade product, the shaft and gear are taken from a decommissioned oil pipeline valve mechanism.

The drum rotates on two bearings that are welded to the winch frame covers.

Drum with gear assembly.

As an option, you can take the drawings of a hand winch drum.

To prevent the cable from flying off the drum, we weld a guide eye to the winch body.

The gearbox is mounted on the winch frame; the author attached the gearbox using a pipe clamp for threading.

We compare the gear of the gearbox shaft with the gear of the drum. Gear ratio 1 x 5.

Reverse connection diagram on a winch.

We wind the cable onto a drum, the thickness of the cable is 6 - 10 mm.

Advice! Do not connect the electric winch to the car battery when the engine is off, the battery will discharge in a few minutes.

Also, you cannot cling to a metal cable the car from which the electric winch is powered; alternatively, you can use a fabric cable or remake the brush assembly on the electric motor, insulating the mass on the winch itself.

A homemade winch from the starter will easily pull a passenger car out of the mud, including a UAZ “loaf”.

Homemade author: Nikolay Evdokimov.

Interesting video: the author shows his homemade winch from a VAZ 21010 starter

Source: sam-stroitel.com

Manual drive: we rely only on ourselves

Hand winches are often used for various repair work, in individual construction, at bases and in stores selling building materials - in general, where it is necessary to lift or move fairly large loads.

A manual winch must have a brake and ratchet stop or a safety handle that combines the functions of a drive handle, stop and brake. This is a guarantee of trouble-free work. Yes, the winch certainly makes the job easier. But we should not forget that it requires, depending on the operation being performed, certain physical efforts, sometimes quite significant. Only after comparing the volume of work ahead and its severity, do you decide to make a construction winch yourself.

Do-it-yourself manual winch: 7 stages of manufacturing the device

How to assemble a car lift for a garage with your own hands

Winches are a very convenient device for lifting loads, which is why it is widely used among car enthusiasts.

Since the cost of special equipment is quite high, a do-it-yourself manual winch will be the best option for motorists who prefer the best price-quality ratio.

Also, using an individual layout, you can create a unique winch that will combine convenience and high load capacity. Compact homemade devices can be installed on any part of the car, which makes the mechanism a universal assistant for repairs and long-distance trips.

Purpose of winches

The winch is one of the oldest mechanisms that man invented and used in his activities to facilitate the movement of heavy objects. The traction force created by the physical strength of a person or animal is transmitted through a rope, chain, cable or other flexible element from the drive drum to the load that needs to be moved.

In a winch, the drum drive can be manual, electric, from an internal combustion engine, from a steam engine, or hydraulic. Most often, a winch is used to lift a load vertically. But sometimes using this mechanism it is convenient to move weights horizontally (for example, a car).

If the winch is firmly installed on the car, then with its help you can independently free yourself from a hole, from a swamp, or climb a mountain. If the stuck car does not have a standard winch, then any other one must be firmly secured to the ground and the problems that have arisen must be solved.

Winch on a car PHOTO: motorsguide.ru

Varieties

There are many types of winches. They can be classified according to manufacturing methods - industrial and homemade; by type of drive - manual, electric, steam, with an internal combustion engine, hydraulic; according to the amount of force developed - powerful, low-power. These characteristics can be combined in various combinations.

Each type has its own advantages and disadvantages. A manual winch is the easiest to make; it is cheap and compact, but it will not be able to develop much power. The maximum weight of cargo that can be lifted with its help does not exceed 1 ton.

The electric winch develops more power. And in the practice of motoring, a car starter can be used as an electric drive. In this case, power comes from a car battery. They are most popular among motorists.

Hydraulic winches are even more powerful, but are complex in design and have low operational reliability. Therefore, they are practically not used by car enthusiasts.

Worm gear – high degree of reliability

Many mechanisms of this type, which have a large load capacity, provide for control of the speed of the cable. Thanks to this, you can change the intensity of the exerted physical effort. A manual worm winch can have a variety of mounting options.

This device is easy to use and highly reliable. Using this element, designed for load-bearing capacity, it is possible to carry out installation, repair and construction work. In this case, the winch will have a high level of safety during operation.

It should have a comfortable handle, and the worm gearbox can provide an excellent ability to hold the load.

How to make different types of winches

In order to take on the development and manufacture of a winch with your own hands, you must be able to work with plumbing tools, welding equipment, electrical appliances and machines.

Homemade winches are created for a specific car. They best meet the needs of the owner, are much cheaper than purchased ones, have high maintainability, are easy to maintain, and are more compact.

One of the most popular options for a homemade winch is created from bicycle parts.

The tools you will need are a grinder, a drill or drilling machine, a screwdriver, a welding machine, a vice, taps, a hammer, a core and something else.

The ratchet, which is needed as a safety device against spontaneous reverse rotation of the drum, is made from a bushing.

Homemade ratchet from a bicycle hub PHOTO: usamodelkina.ru A body is made from a steel strip into which the hub with the ratchet is inserted. The main part of the winch is ready.

Device with ratchet assembly PHOTO: usamodelkina.ru

Device types

Classification is the first thing you need to know about the traction device. They are divided depending on the type of design, drive and technical features. Some types of winches are easy to make yourself - this is the simplest mechanism with a manual drive .

And complex structures will work reliably only if they are manufactured in a factory. This specificity must be taken into account when choosing a type for self-production. There are removable and stationary winches. The first option can be removed from the car, carried out maintenance or used for other economic purposes.

Classification depending on the type of drive:

- Manual. Its advantages are its small size and relatively light weight. The work is carried out according to the drum principle. The cable is pulled onto a separate reel, and it is rotated by hand. The disadvantage lies in the limitation of the mass with which work can be done - no more than 1 ton.

- Mechanical. The drum with the cable is rotated by the machine's engine. The design is heavy, so car enthusiasts rarely use it.

- Electric. The best option is for the drum to be driven by an electric motor. The latter is powered by a battery or the vehicle's electrical system. The load capacity in this version is 4 tons.

- Hydraulic. The design is complex, but it works silently and with great traction force. But such systems are unreliable and expensive. Another drawback is that it is impossible to make a hydraulic drive system yourself.

The manual winch is ideal for DIY. The system has a simple design that can be easily made from available materials. There are no complicated moving parts. You just need to decide on the parameters. If desired, you can install an electric motor on such a device, which will eliminate physical labor.

Drum hand winch

How to make a muffler with your own hands? DIY muffler repair without welding

The easiest way to make a winch with your own hands is to make a manual drive that drives the drum. To do this, you can use improvised means. The most commonly used parts are bicycle parts.

The drum is operated manually, so this unit is not designed for high loads, but is quite suitable for domestic use.

The design includes the following elements:

- drum;

- gearbox;

- support;

- lever.

The following types of drums can be used:

- toothed;

- worm.

If you plan to move heavy loads, it is better to use a worm drum. It significantly increases the force applied to the handle. Such a drum does not require manual braking; it locks automatically when the force is no longer applied to the handle.

The downside is the worm mechanism itself, which has a complex design. The unit requires regular lubrication. A manual winch, made with your own hands from a toothed drum, is less demanding in maintenance, easier to repair, but is designed for lighter loads.

What is a winch for?

How to make the dimensions of turn signals on vases. how to easily make “American turn signals” with your own hands

If the car is not equipped with such a device, then you can purchase it and install it on your vehicle. But it is quite possible to make a winch with your own hands. Many car enthusiasts already use homemade winches from a starter. By the way, most people claim that homemade winches are even more reliable than their factory counterparts.

There are several types of such a device. These types differ depending on the energy that drives the actuator. It is impossible to immediately say which of the existing types of winches can be called preferable and best, since they are used in different situations.

Homemade winch for Niva

In some serious way, assembling and installing a winch on a Chevrolet Niva is no different from the same work on other SUVs. One of the features of the Niva is its light weight, so it is recommended that the winch pull be 3-3.6 tons. Sometimes it is advised to install a mechanism with a 4-ton thrust, but this will pull the front of the car down while driving. If you plan to travel long distances off-road, you need a spare battery (for the electric winch).

The height of the role itself is not important, since the vector of application of the load force depends on the location of the rollers through which the cable passes.

Homemade winches from various materials

A winch can be made from a variety of readily available materials. These are mainly spare parts from automotive equipment, other devices and mechanisms whose service life has expired. Finding available materials - metal pipes, iron sheets, different types of cables is also not a problem. There are several types of winches that are increasingly popular.

Winch from starter

A DIY starter winch is a convenient option for saving money. In order for a homemade winch from a starter to realize its potential, you will need:

- 12 volt gear starter (easy to find from VAZ 2106 or 2110).

- As a gearbox (reduction), you can get by with a drill assembly.

- For the casing that covers the space between the engine and the gearbox, a piece of pipe (for example, PVC) is suitable. It should be easy to disassemble for access inside and maintenance of the device.

- The drum is often made of durable (from 120 mm) steel pipe and sheet iron (2-3 mm).

- Gears, cable, electrical wiring.

To make such a winch from a starter, a platform is made from a sheet of metal, and components are attached to it. The drum seats are then welded to it. The gearbox is welded so that the input shaft is on top. An adapter for the starter is attached to the gearbox, and gear teeth are attached to the input shaft. For this, the flywheel crown is used. Then the starter and wiring are attached.

Winch from wiper motor

To make a winch, you can use a motor that previously used a windshield wiper or windshield wipers for its work. These devices are capable of showing good results and lifting weights up to 300 kg.

It is popular to use such a mechanism to mount a blade on a vehicle of sufficient cross-country ability (for example, Niva) - for clearing snow or similar tasks.

Winch from KAMAZ ratchet

A truck brake ratchet (a self-leveling mechanism for adjusting brakes) is a popular option for a homemade winch. Many people use the KAMAZ version of the ratchet, since KAMAZ is widespread and parts from it are easy to find. Such a mechanism can lift from 400 kg to 2 tons. The popularity of this option is due to the use of a worm gear in the mechanism.

For production you will need:

- Two rear ratchets of the truck.

- Two hooks.

- Cable 4-5 mm thick.

- Fist for releasing brake pads.

- Bolt for fastening the hook.

Worm gear winch

The main convenience of a worm gearbox, in addition to its load capacity, is the ability not to use a drum brake. One of the popular options for such a winch is a gearbox from trolleybus doors. It has enough gear ratio for fairly heavy loads and is easy to mount.

What can be useful for a winch made from scrap materials

To make a homemade winch, any scrap and any working parts that are within reach will be useful. The source of the motor for the electric winch can be a chain saw, a motor scooter or an automatic washing machine (if the motor is running). Cuttings of thin-walled and thick-walled pipes, bearings, gears, starters from old cars, ratchets from trucks, a motorcycle clutch disc, etc. will be useful. You will only have to buy a cable and something not very expensive. A welding machine and a lathe will suffice as equipment.

Homemade winch “grandmother” to pull the car yourself (old-fashioned way)

There have been cases when sunken cars, both cars and trucks, were raised from the bottom of Lake Baikal. From a depth of more than 100 meters and weighing up to 5 tons!

That’s why such a homemade “grandmother” winch can be stronger than a tank. There's a lot of dope in it!

And now about the homemade product itself.

My grandfather made an original device from scraps in his garage for pulling out a car if it got stuck.

I took a steel pipe and welded a metal “ear” to it on the side. In another piece of pipe, he made 2 holes opposite each other and welded a nut in their place, and a bolt to them - it turned out to be a kind of clamp.

They also need: a steel pin, a sledgehammer and a reliable and strong cable.

This pin is driven into the dense ground, and first, a “hole” is drilled out with a hand-made homemade drill.

He puts his “devices” on the pin. One end of the cable is attached to the machine, and the other to its own device.

And then he inserts the handle of a shovel into the “ear” (he says that those who go hunting or fishing in the forest always take a shovel with them). You can use a crowbar.

And it starts to spin, and at the same time the stuck car itself slowly begins to emerge from the hole. It turns out to be a kind of hand winch.

It is better to use a cable of the “Hercules” type - this is a strong rope - a combination of steel wire and synthetic rope. Well, the car one often copes.

Watch the video where the grandfather explains the design of a homemade “grandmother” winch and shows with an example how to use it yourself:

To be on the safe side, you can modify your grandfather’s homemade product. Weld another ring on top and tie a couple of guy wires to them, which in turn are attached to stakes 5 meters away at an angle of 70-80 degrees. Source

DIY car winch

Sooner or later, anyone who often travels off-road understands the necessity of such a simple device as a car winch.

Homemade winch with a force of 4.5 tons

Now the market offers a large selection of devices, the price of which varies depending on the traction force, the complexity of the design and the arrogance of the manufacturer. Another way out is a do-it-yourself winch.

Of course, not everyone will decide to take such a step, because it is much easier to install a purchased device on a car, but for a home-made person this is not an option, and he will definitely be puzzled by making his own “lifesaver” for his car.

Components of a homemade winch

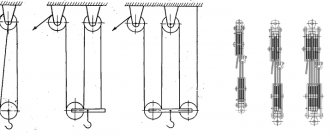

A drum with a cable is the main component of any winch, homemade or industrial, let's start with it.

If you can find a ready-made drum that doesn’t require any modifications, then that will be just great, but if you don’t have one at hand, then you’ll have to make one. To do this, you need to take a piece of thick-walled pipe and weld cheeks 4–5 mm thick to it.

Depending on the design of the winch, a driven gear can be welded to one of the drum cheeks, and the pipe is equipped with seats for bearings.

An example of a homemade drum

As an option, you can use a pair of hubs from a Zhiguli to make a drum. You will only need to grind the welding area (thin end) and weld the drum halves on a mandrel of a suitable diameter to ensure alignment of the parts.

It is preferable to use a worm gearbox with a large gear ratio.

The advantage of a worm gearbox is that when using it, a do-it-yourself car winch can do without a drum brake (due to the properties of the worm pair).

As an example, we can consider the gearbox from trolleybus doors; it has a sufficient gear ratio and is easy to mount on the site.

When using it on a winch, you need to open the housing and lock the bevel clutch, which is designed to protect passengers from being pinched by the doors. This can be done in any convenient way, the simplest of which is to attach the cone to the gear by welding in several places.

If it is assumed that a do-it-yourself electric winch is made using a starter, then it is better to use one that is equipped with a planetary gearbox (some Zhiguli motors are equipped with such a unit).

How to make a winch from a starter

We make a platform from a sheet of metal on which all the nodes will be attached. Then we weld the seats for the drum shaft to it and install it. After this, we attach the gearbox (with the input shaft up) and weld its mounting plate in place.

On top of the gearbox we attach a homemade adapter for attaching the starter, and on the input shaft we attach a gear with a suitable tooth module (you can use the flywheel crown). We fix the starter and arrange the wiring, install it on the car and use it.

Manufacturing a system with a universal drive

The manual system is easy to manufacture. Of the special skills the master is required to do, only own a welding machine. Any metal will do the job. The appearance of the device is not so important, the main thing is performance and resistance to heavy loads. The frame should not be deformed.

Materials and tools:

- Rectangular tube for frame.

- Shaft for the drum, you can use a round tube.

- A sheet of metal with a thickness of at least 3 mm for the manufacture of drum disks.

- Threaded rods M10-M12, 24 cm long – 6 pieces, nuts.

- Tube diameter 14 mm - 6 identical pieces of 20 cm.

- Asterisks - large and small. Chain.

- Hubs to secure the drum to the shaft and secure the shaft to the frame.

- Drive lever.

- Cable with carabiner.

- Welding and electrodes.

- Grinder and grinding disc for it.

- Paint and primer.

- Wrenches included in the set.

Some materials are better purchased - for example, tubes for the studs and shaft. The rest can be picked up from old mechanisms - cars or motorcycles. Any metal will do, even used.

Manufacturing procedure:

- They sketch out a drawing, because this will make it easier to navigate during assembly - you won’t have to stand guessing over the half-finished product and think about what to do next.

- Cut out the frame parts from a pipe with a cross-section of 2 by 2 cm. Connect the frame parts together strictly perpendicularly. The cut on the workpieces is made at an angle of 45 degrees.

- Lay the frame blanks on a flat surface. The joints are spot-tightened by welding, after which they check whether everything is installed correctly. The angles of the connections must be strictly 90 degrees. If there is a lack of accuracy, corrections are made and then the parts are welded.

- Scale is removed with a grinder and a grinding wheel. The finished frame is sanded and then coated with a primer. After the latter has dried, the metal is painted with enamel in 2 layers. You can use regular paint. The goal is to protect the metal from corrosion, since operating conditions will be difficult, with dirt and moisture.

- Creating a drum. Take a sheet of metal and cut out 2 circles, their diameter is about 30 cm. On each circle you need to make 7 holes:

- One in the center. The diameter must match the shaft size.

- 6 holes at a distance of 7 cm.

- The discs are fastened together using pins. The pin is inserted into the hole of one disk in a vertical position. Tubes with a diameter of 14 cm are put on the studs, and a second disk is installed on them. The studs must not only be secured with nuts, but also additionally reinforced with locknuts to ensure reliable connections.

- The drum is ready, now the shaft is mounted. It is made from a metal pipe, but you can take a finished product from any mechanism. The latter option is preferable: since the accuracy of the factory part is higher, vibrations of the drum will be small or absent altogether.

- A large diameter sprocket is mounted on the shaft on the outside of the drum. A sprocket from a motorcycle gearbox will do. To secure the drum to the frame, the outer sides of the shaft must have hubs.

- The drum assembly with the shaft is mounted through the hubs on the frame. The structure is secured with bolts. Before installing the drum, you should prepare a platform on the frame. A drive will be installed on it - manual or electric. When using an electric drive, a motor is placed on the platform with a small sprocket attached to its shaft.

- A universal drive is often installed: a handle is placed on the reverse side of the output shaft of the electric motor. In the absence of electricity, the winch can be turned manually.

- It is important to properly tension the chain. It should not sag, but strong tension is also unacceptable - this will cause the sprockets to wear out faster, and the chain may break. Check the chain tension by rotating the drum - the chain should not hinder its rotation when the cable is unwound.

- The end of the cable is secured to the shaft and wound around the drum. A carabiner is hung on the other, free end of the cable.

- A shank is attached to one end of the frame. With its help, the winch is secured to the car frame.

The winch is created in a day. Since it will be installed on an SUV, the operating conditions will be appropriate. To prevent dirt and sediment from getting on the drum, it is covered with a casing. This way the mechanism will last longer and the cable will not wear out.

The design is simple, reliable, and easy to make yourself . Yes, it does not have the ability to change the gear ratio, there is no reverse and other additional functions. A self-made electric winch is capable of dragging a heavy load across the terrain, be it a car or something else.

Winches, their types and capabilities

If you have ever lifted a bucket of water from a deep well by turning a winch, you already have an idea of how a winch works. A winch is a machine for lifting or moving loads. It consists of a drum or pulley for the load rope, a drive mechanism with intermediate gears, a braking device and a support frame. Depending on their purpose, these mechanisms are divided into traction (moving loads horizontally) and lifting.

Nowadays, it is difficult to imagine loading and unloading, construction, repair, warehouse work, car service without these simple and reliable devices, which have been tested over the centuries and are constantly being improved. Along with mechanisms for mooring ships, lifting anchors, winches as part of a large number of machines, a homemade hand winch successfully operates - the best option when building a country house.

A few words about the classification of winches. Depending on the installation method, there are

- stationary,

- portable (placed on a temporary basis),

- mobile (with frames having road rollers).

Based on the type of traction force transmission, a distinction is made between winches with winding drums and winches with friction drums or pulleys. The use of manual or machine drive determines two main types of winches. Horse-drawn vehicles - oxen or horses - are a thing of the past. Therefore, if you are not capable of pulling force equivalent to the work of a pair of oxen, your choice is an electric winch installed by yourself.

Varieties

There are several classifications of winches. The main purpose of the devices is to lift and move loads, so they are used in many areas. Motorists are faced with the need to lift heavy loads quite often. Lifting large components and assemblies in the garage or towing requires reliable securing of loads. Depending on the installation method, winches are divided into 3 types:

- Stationary . Installed on walls, ceilings, beams and other structures. Most often used in large car repair shops.

- Portable . Can be mounted on any suitable surface.

- Mobile . Installed on platforms on wheels. For a small garage, this type of construction is the most preferable.

A manual winch for a car is the most common among car owners. A manual drive is convenient for lifting loads in a garage, but its design must be carefully thought out.

The mechanism must have a brake system and a ratchet stop.

In the absence of these devices, operation of the winch is unsafe.

Machine-driven units require one or two drums. Such mechanisms are used mainly in elevators, cranes, and drilling rigs. When used in a garage, a drum-driven winch can make carrying and lifting objects much easier.

We make a winch ourselves or buy it

Unlike manual winches, electric winches are more powerful and have a greater lifting capacity. True, the cost is much higher. And therefore, in order to save money, it makes sense to think about making a homemade device.

In this article we will tell you how to make an electric winch with your own hands, using scrap materials and used parts.

Some may think that making an electric winch with your own hands is difficult. But actually it is not.

If you have the tools and straight hands, everything will work out. You can buy an electric motor inexpensively second-hand or find it at a metal receiving yard (ferrous metal shop) - there is a lot of this junk there.

In general, there are many options for winches with different drives. It is not necessary to use a 220 V electric motor. For example, you can make an electric winch from a car starter. This is one of the most popular options.

In addition, some home craftsmen often make electric winches from a screwdriver or drill. Also quite a working option. True, you shouldn’t count on a large load capacity.

You can also use different gearboxes for winches: worm gears or regular gears, which consist of a large and a small gear.

We will talk in detail about choosing a gearbox a little later, but for now let’s look at several options for homemade devices made from scrap materials.

Homemade winch for UAZ

Technical characteristics allow you to install homemade winches of any type on the UAZ, the most popular option is an electric winch. It allows you to pull out the UAZ even if the engine has stalled. Easy to use and reliable. Cons: short battery life and vulnerability to moisture. When installing a homemade winch on a UAZ, if it is electric, it makes sense to increase the battery power or carry a spare one.

IMPORTANT! It is possible to install a hydraulic winch, but only with a hydraulic booster. Manual and mechanical (shaft) winches are also used.

Manufacturing process

Having chosen a specific engine for a homemade winch and self-puller, having found a gearbox for it, it is necessary to begin the production of the main structural parts. The first thing you should ask yourself is what to make a cable winding drum from? It can be made from a cylindrical motor housing or from a steel pipe of suitable diameter. In this case, it is easier to find a piece with a diameter of 100 mm. This is the best option.

Next, it is necessary to make flanges for the drum, which are welded to it. A shaft is rigidly inserted into them, which rests on the supporting structure - the winch frame through bearings. The shaft is connected through a coupling to the secondary shaft of the gearbox, the housing of which is rigidly attached to the winch frame. The motor is attached to it.

It should be remembered that planetary and cyclic gearboxes require the use of brake couplings, for which you can use a solenoid and brake brushes that will be pressed against the shaft. The brake is needed in order to more accurately perform any actions with the winch, especially when it is necessary to lift or lower the load as carefully as possible.

It is necessary to attach a cable to the drum, for which a hole is drilled in the pipe, where one end is threaded and mechanically secured in the cylinder. It will pass through the guide eye; for smooth movement, you can use an additional roller. If it is necessary to increase the traction force, a roller system can be used. In this case, the design of the winch will become more complicated and larger.

The winch operation is controlled remotely using a radio frequency control panel or by wire. You can buy ready-made radio modules for receiving/transmitting signals or make them yourself. It’s easier and more reliable to use a wired remote control. You will need to use only 2 buttons: winding the cable and winding it.

Originally posted 2018-07-04 07:36:32.

Design and structure

If you need to make a winch for a car or an ATV, especially if you are regularly involved in extreme sports, then first of all decide on the weight that the winch will need to lift. For example, the average weight of an ATV is only 400 kg, so a winch with a traction force of up to 700 kg or 1 ton is sufficient for it. If we are talking about a car, then a more powerful unit with a lifting capacity of at least 3 tons is required.

Important! You should buy or make a winch yourself with a reserve, otherwise you can find yourself in a hopeless situation in a difficult situation.

So, its power will depend on the applied load on the winch, and accordingly, the dimensions of the mechanism, whether it is electric or a hydraulic winch, does not matter. The more powerful it is, the larger its size will be, which is quite understandable. The first step is to understand the design. Although, in essence, they will differ only in the drive device, otherwise they are similar. The design of any winch includes the following functional units:

- Drive motor. An organ that creates the initial torque transmitted through the gearbox to the drum.

- The gearbox is planetary or simple stepped or worm. The design depends largely on the weight of the load, but generally a planetary reduction mechanism is used.

- The shaft on which the drum is located. A cable is wound around it during the process of lifting a load or dragging it. In simple automobile winches, designed for light weight, there is only one; in powerful ones with a traction force of more than 10 tons, there can be 2 or more, which is explained by the theory of blocks.

- Cable with hook. One of the main components due to which the load is dragged. Usually it is made of steel from individual cores.

DIY electric plowing winch

A homemade winch is designed to facilitate heavy manual labor when cultivating the soil and can replace any walk-behind tractor or cultivator. With its help, you can plow the soil under the beds, plant, harrow, hill, dig up potatoes.

The agricultural winch allows you to carry out a full cycle of soil cultivation when growing potatoes. The unit helps preserve and maintain soil fertility, which leads to maximum yield.

In the distant 90s, a plowing winch was created based on the engine from the Ural, Druzhba chainsaw, and it still serves faithfully to this day. Changes and improvements concerned mainly the plow. The video below clearly shows these changes. See winch drawings here. Gradually the idea came to create an electric analogue. And this is what happened, see the video and photos below.

A winch was made - a walk-behind tractor from scrap materials using standard publicly available parts and ordinary materials (electric motor 2.2 kW 1500 rpm, pipes, angles, sprockets and chains from motor vehicles).

Electric plowing winch

The motor is three-phase and connected to a single-phase 220 V network. This power is enough for plowing, hilling, and digging up potatoes. If you buy a motor for a single-phase network, you can plow virgin soil. And in my modification for plowing virgin soil, I used a block that reduces the plowing speed by half, but also increases the effort.

Tips for use

In order for a homemade winch to serve for a long time, you need to follow a few simple rules:

- The device must always be secured as securely as possible to the base or support.

- Bearings and other moving parts need to be lubricated regularly. Liquid or thick lubricants can be used.

- Before operation, you should check the functionality of all components.

- The winch must be installed so that the load is within the person's field of vision.

- The maximum permissible load must not be exceeded. This is fraught with the risk of breaking the cable, breaking the winch itself and injuring people.

- Do not touch the cable while lifting the load.

How can you do without a winch?

If you don't have a winch and the time to make one, there is an easy way to assemble the following design:

Take a crowbar, a piece of pipe, a strong cable. The crowbar must be buried deep in the ground. The tool is used as a rotation axis. A tube is used as a lever. Metal pipes are fastened with a crowbar perpendicular to the ground

The axis will rotate, so it is important to securely fasten the elements (for example, by welding). The cable is attached with a carabiner to a crowbar, and the other end to the object that needs to be moved. Next, using a tube, the cable is wound onto the axle. The longer the pipe, the easier it will be to wind.

Block required for winch operation

A hand winch mounted on the floor or workbench can only move objects horizontally. To lift heavy objects to a height, you need an additional device - a block. It is a pulley with a suspension through which the cable is thrown.

The drawing shows the mechanism of operation of a set of winch and block.

Moreover, this device has additional capabilities. Each added block doubles the force on the cable.

This property of block drives is widely used in rigging work. In a compact design, the winch is assisted by a block amplifier.

All of the above devices are sold for a lot of money. And any of these products can be made independently.

To make a homemade product you will need materials:

- Ratchet for trucks.

- A pair of bearings.

- Sheet metal.

- Cable.

- Washers.

- Hook.

This is the ratchet we need, remove the side covers from it.

You will also need this cable.

We insert a piece of pipe of a suitable diameter into the ratchet and weld the pipe to the gear.

Next we will need these washers.

We weld the washers to the shaft, resulting in two reels for winding the cable.

We'll paint the winch.

Now let's make another mechanism, take two inner races from the bearings.

We weld the clips to the plate like this.

We weld a hook to the plate on the back side.

That's all, the homemade hand winch is completely ready for use. On one side we wind the cable onto reels, on the other side we put it on a block with a hook and turn the ratchet.

With the help of such a winch, you can pull out a stuck car; the winch is compact and will not take up much space in the trunk; it can come in handy at the right time.

Do-it-yourself winch from the starter

A homemade winch from a starter is made from materials that are always available in the garage. The basis, of course, is the starter, and the device itself runs on battery power.

It is desirable that the gearbox for the winch be planetary. You can find it on old Zhiguli models.

WATCH THE VIDEO

For manufacturing you will need: cables, cable, gears, drum, starter, gearbox, sheet of metal.

- Secure the drum seats with bolts and a welding machine.

- Assemble the drum with gearbox.

- The starter is assembled to the gearbox using adapters.

- Equip the input shaft with a gear. It is necessary to ensure that the size of the teeth matches the design. If the shaft connects freely to the gear, then the manufacturing process is proceeding correctly.

- Place the gear onto the cylinder. After the structure is securely fastened, the electrical wiring is connected.

A homemade hand winch can be of several types.

Lever

A manual lever winch with your own hands can work suspended and does not require fixation to the base. When pressing on the lever, or rather, performing rocking movements, the ratchet mechanism begins to move. A crowbar or shovel is often used instead of a lever. A piece of pipe is put on the “axis”, to which the cable is attached. A lever is slipped under the bottom turn, which is rotated to move the car from its place.

WATCH THE VIDEO

Simple drum

A homemade winch for a manual type farm has a manual drive, due to which objects move. The design includes a drum, gearbox, handle and support. The drum can be either gear or worm.

A do-it-yourself worm winch has a high gain. Another advantage is that it is self-locking. This means that if you stop making efforts, it will stop working.

WATCH THE VIDEO

The disadvantage is friction in the worm pair, but this problem can be solved with high-quality lubricant. A homemade winch requires only a few parts.

Assembly technology

When starting work, you need to clearly understand that a homemade winch should be reliable, easy to use and inexpensive in terms of financial costs.

Such a product has the advantage that when assembling it with one’s own hands, a person knows all the design features in great detail. Moreover, a certain part of car owners believe that homemade means high quality. You can assemble the winch from the starter within an hour. Provided that all components are available, the tools are in working order, and the master is sober.

The drum with the cable is the main working unit of the winch. The work will be completed faster if such a unit is available. If you don’t have one, then you can easily make a drum yourself from a thick pipe and sheet metal 3-5 mm thick. The cheeks are simply welded to the pipe on both sides. A gear is attached to one of them, to which force from the gearbox will be supplied using a transmission chain. The drum can be made from a pair of used Zhiguli hubs. To do this, just cook them on the thin side. This must be done on a mandrel in order to ensure alignment of the parts.

When choosing a gearbox, you need to be guided by the consideration that a homemade automobile winch can function without a stopper.

Experts in their field recommend using a gearbox in this case, which is used to open and close trolleybus doors. It's good if you can find it. If this is not possible, the winch must be assembled differently, from the starter. In this case, it is preferable to use a starter model that is equipped with a planetary gearbox. It is compact in size and not heavy in weight. These parameters must be taken into account when designing the product.

A homemade winch, according to current rules, must be mounted on the front bumper of the car. Although car enthusiasts also use a portable version of the product. You can load it into the trunk by hand and easily take it out when the need arises. In any case, it should have minimal dimensions. This feature of the mechanism must be taken into account during design. By doing the work yourself, you can regulate all work processes without rushing or forcing the assembly process.

When performing the assembly yourself, you need to pay special attention to the installation of electrical wiring and switching. It is advisable to secure the winch control panel away from rotating parts.

This will reduce the risk of injury due to negligence.

A homemade winch, if assembled correctly, will last much longer than its factory counterparts

This will reduce the risk of injury that could be caused by negligence. A homemade winch, if assembled correctly, will last much longer than its factory counterparts