An induction furnace can be used to melt small amounts of metal, separate and purify precious metals, and heat metal products to harden or temper them.

In addition, such stoves are proposed to be used for heating the home. Induction furnaces are commercially available, but it is more interesting and cheaper to make such a furnace yourself.

DIY induction heater

An induction heater is an indispensable thing for blacksmiths, turners, mechanics and home craftsmen. With its help, you can always easily and quickly heat and even melt metal; you do not need expensive coolants such as coal and gas; you just need to connect electricity to the device. Non-contact heating of the metal occurs with high-frequency currents, scientifically called radio-frequency waves. The device is widely used for heat treatment, hardening and bending of parts, non-contact melting, soldering and welding of metals. In jewelry making for heat treatment of small parts. In medicine for disinfection of medical instruments. In a car repair shop, a mechanic heats up rusted nuts. The inductor is also installed in induction boilers used for heating residential premises.

This picture shows a working diagram of an induction heater, which you can easily make with your own hands.

Induction heater circuit

The device consists of a high-frequency master oscillator assembled on two powerful field-effect transistors. The operating voltage of the generator depends on the power of the installed field-effect transistors. With IRFP250 transistors, the device can be powered with voltage from 12 to 30 volts. And if you install IRFP260 transistors, then the supply voltage can be raised from 12 to 60 volts.

The power of the inductor will increase noticeably, the heating temperature of the metal will rise to more than 1000 degrees, which will allow the metals to melt. During operation, the transistors will become very hot, so they must be installed on large radiators and a powerful fan. At idle, the inductor consumes at least 10A, and in operating condition at least 15A; accordingly, a very powerful power supply of at least 20A is required.

This picture shows the PCB of an induction heater.

You will also need 10K resistors R1, R2 with a power of 0.25 Watts. Resistors R3, R4 with a resistance of 470 Ohms of at least 2 Watts. Diodes D1, D2 ultra-fast UF4007 or other similar ones for a maximum current of up to 1A. Zener diodes VD1, VD2 with a power of at least 5 Watts with a stabilization voltage of 12V, for example 1N5349 and others. I pulled out chokes L1, L2, 27x14x11 mm in size, yellow with a white stripe, from computer power supplies. For each choke you need to wind 25 turns of copper wire with a diameter of 1 mm, preferably in varnish insulation; if you can’t find it, a single-core wire in PVC insulation will do; it does not greatly affect the speed.

Metal film capacitors C1-C16 0.33 uF 630V, connected in parallel in 4x4 rows, there are only sixteen pieces in the block. It’s better not to install it with a lower operating voltage; they will get very hot. Leave a small distance between the condensers for good cooling by air flow.

I decided to glue the chokes with silicone sealant so that they would not dangle.

I made an important part of the heater, the inductor, from a copper tube with a diameter of 6 mm and a length of 1 meter. You can buy one at any auto store like “Gazovshchik” and where they sell gas equipment for cars. We wind the copper tube onto a piece of polypropylene pipe with an outer diameter of 40 mm; such a pipe is used in plastic heating. We make five turns, the distance between the top edge of the first turn and the bottom edge of the fifth turn should be 40 mm. We bend the ends of the pipe as in the figure and attach them to the radiators using two terminal blocks for a wire with a cross-section of 16 mm?.

During operation, the inductor will become very hot from the hot part, which can lead to damage to the copper tube, so cooling must be done. I put silicone tubes on the ends of the copper tube and connected the car windshield washer pump. I bought a pump from a VAZ 2114 and silicone tubes at a car store. The result was a normal water cooling system.

To cool the radiators and capacitor unit, I installed a powerful fan from the processor. For power supply from 12 volts, such cooling is quite enough. If you want to increase the voltage from 12 to 60 volts in order to get maximum power from an induction heater, install more powerful radiators and a more efficient fan, for example from the interior heater of a VAZ 2107. It is advisable to make a metal curtain that protects the heated part and the copper inductor from the flow of cold air forced by the fan .

Since the induction heater consumes a large current of about 20A, all traces on the PCB should be reinforced with copper wire soldered on top.

And now the most interesting part... I tested the induction heater using a twelve-volt car battery. I simply do not have another power source capable of delivering high currents. The blade of a stationery knife became red hot in 10 seconds. And this is a good result, considering that the inductor is powered by only twelve volts!

Friends! If you want to assemble an induction heater with your own hands. My advice to you... Immediately install IRFP260 field-effect transistors, large radiators and a powerful fan from the VAZ 2107 interior heater; to power the inductor, be sure to use a powerful power source, preferably from 24V to 60V with a current of at least 20A.

Radio components for assembling an induction heater

- Transistors T1, T2 IRFP250 are better than IRFP260 2 pcs.

- Resistors R1, R2 10K 0.25W 2 pcs. R3, R4 470R 2W 2 pcs.

- Ultrafast diodes D1, D2 UF4007 2 pcs. or similar

- Zener diodes VD1, VD2 for 12V 1W 1N5349 or similar 2 pcs.

- Capacitors C1-C16 0.33mf 630V 16 pcs.

- Chokes from a computer power supply are yellow with a white stripe, size 27x14x11 mm, 2 pcs.

- Terminal block for wire with a cross section of 16 mm? 2 pcs.

- Copper wire in varnish insulation d=1 mm length 2 meters

- Copper tube d=6 mm, length 1 meter

- The bigger the better the radiator 2 pcs.

- Windshield washer pump from VAZ 2114 1 pc.

- Silicone tube 2 meters

- The more powerful the fan, the better. I recommend from the interior heater VAZ 2107 1 pc.

Friends, I wish you good luck and good mood! See you in new articles!

I recommend watching a video on how to make an induction heater with your own hands

Schematic electrical diagrams, connecting devices and pinouts of connectors

Equipment cooling

When creating an induction furnace with your own hands, the biggest problem that arises is cooling. This is due to the following points:

- During operation, not only the molten metal is heated, but also some elements of the equipment. That is why effective cooling is required for long-term operation.

- The method based on the use of air flow is characterized by low efficiency. In addition, it is not recommended to install fans near the stove. This is due to the fact that metal elements can influence the eddy currents generated.

Typically, cooling is carried out by supplying water. Creating a water cooling circuit at home is not only difficult, but also economically unprofitable. Industrial versions of the furnace already have a built-in circuit, to which it is enough to connect cold water.

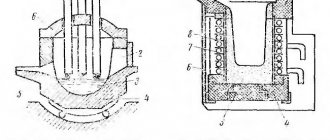

Operating principle of the HDTV installation

The coil creates a high-frequency magnetic field, and eddy currents appear in the metal object in the middle of the coil, which will heat it up. Even small coils pump a current of about 100 A, so a resonant capacitance is connected in parallel with the coil, which compensates for its inductive nature. The coil-capacitor circuit must operate at their resonant frequency.

Homemade HDTV coil

Video on the topic

For many years people have been smelting metal. Each material has its own melting point, which can only be achieved using special equipment. The first furnaces for melting metal were quite large and were installed exclusively in the workshops of large organizations. Today, a modern induction furnace can be installed in small workshops when setting up jewelry production. It is small, easy to use and highly effective.

Electrical circuit diagram

Here is the original circuit of the induction heater generator, and below it is a slightly modified version, according to which the design of the mini HDTV installation was assembled. There is nothing in short supply here - you only have to buy field-effect transistors; you can use BUZ11, IRFP240, IRFP250 or IRFP460. The capacitors are special high-voltage, and the power will be from a 70 A/h car battery - it will hold current very well.

The project turned out to be surprisingly successful - everything worked, although it was assembled “on the knee” in an hour. I was especially pleased that it does not require a 220 V network - car batteries allow you to power it even in the field (by the way, can you make a camp microwave out of it?). You can experiment in the direction of reducing the supply voltage to 4-8 V as from lithium batteries (for miniaturization) while maintaining good heating efficiency. Of course, it won’t be possible to melt massive metal objects, but it will work for small jobs.

The current consumption from the power supply is 11 A, but after warming up it drops to about 7 A, because the metal resistance increases noticeably when heated. And do not forget to use thick wires here that can withstand more than 10 A of current, otherwise the wires will become hot during operation.

Heating a screwdriver to blue HDTV

Heating the knife HDTV

Features of operation

An important issue when using an induction oven is safety.

As mentioned above, crucible-type furnaces use high-frequency power sources.

At the same time, self-made generators can emit parasitic high-frequency vibrations, which can cause certain harm to human health.

Therefore, when operating an induction furnace, the inductor must be positioned vertically; before turning on the furnace, a grounded shield must be put on the inductor. When the furnace is turned on, it is necessary to observe the processes occurring in the crucible from a distance, and after completing the work, immediately turn it off.

When operating a home-made induction furnace, you must:

- Take measures to protect the oven user from possible high frequency radiation.

- Take into account the possibility of burns from the inductor.

When working with a stove, thermal hazards must also be taken into account. Touching the skin with a hot inductor can cause severe burns.

The second version of the circuit is powered from the network

To make it more convenient to adjust the resonance, you can assemble a more advanced circuit with the IR2153 driver. The operating frequency is adjusted by a 100k regulator at resonance. Frequencies can be controlled in the range of approximately 20 - 200 kHz. The control circuit needs an auxiliary voltage of 12-15 V from the network adapter, and the power part can be connected directly to a 220 V network via a diode bridge. The inductor has about 20 turns of 1.5 mm on an 8×10 mm ferrite core.

Diagram of an induction heater from a 220V network

The working HDTV coil should be made of thick wire or better copper tube, and has about 10-30 turns on a 3-10 cm mandrel. Capacitors 6 x 330n 250V. Both get very hot after a while. Resonant frequency is about 30 kHz. This homemade induction heating installation is assembled in a plastic case and has been working for more than a year.

How to use safely

It is quite easy to get burned from the structure and molten metal, so you need to work with a homemade installation carefully. The circuit of the lamp sample involves the use of high voltage, without a good housing, any touch can result in an electric shock.

Clothes should not have metal inserts, because the electromagnetic field will affect them. A high-quality induction furnace, designed with your own hands, can heat elements quite efficiently, which will be convenient for tinning or molding. Experts do not recommend working with the equipment for people who have implanted pacemakers.

induction oven from microwave

About the MosCatalogue.net service

MosCatalogue.net is a service that provides you with the opportunity to quickly, free of charge and without registration, download videos from YouTube in good quality. You can download videos in MP4 and 3GP formats, and you can also download any type of video.

Search, watch, download videos - all for free and at high speed. You can even search for movies and download them. Search results can be sorted, making it easier to find the video you're looking for.

You can download movies, clips, episodes, trailers for free, and you do not need to visit the Youtube site itself.

Download and watch an ocean of endless videos in good quality. Everything is free and without registration!

Advantages of Melting

Induction heating is direct, non-contact and its principle allows the generated heat to be used with maximum efficiency. The efficiency factor (efficiency) when using this method tends to 90%. During the melting process, thermal and electrodynamic movement of the liquid metal occurs, which contributes to uniform temperature throughout the entire volume of the homogeneous material.

The technological potential of such devices creates advantages:

- performance – can be used immediately after switching on;

- high speed of the melting process;

- possibility of adjusting the melt temperature;

- zonal and focused energy orientation;

- uniformity of molten metal;

- no waste from alloying elements;

- environmental cleanliness and safety.

Principle of operation

The basis of an induction furnace is to obtain heat from electricity generated by an alternating electromagnetic field (EMF) by an inductor (inductor). That is, electromagnetic energy is converted into vortex electrical energy, and then into thermal energy.

Eddy currents closed inside bodies release thermal energy, which heats the metal from the inside. Multi-stage energy conversion does not reduce the efficiency of the furnace. Due to the simple operating principle and the possibility of self-assembly according to circuit diagrams, the profitability of using such devices increases.

These efficient devices, in a simplified version and with reduced dimensions, operate from a standard 220V network, but require a rectifier. In such devices, only electrically conductive materials can be heated and melted.

Benefits of heating

- does not require a separate room, is silent;

- duplication with other heating methods is possible;

- no preventive maintenance is required;

- the scale level is minimal due to constant vibration of the system;

- any liquid coolants are applicable (water, antifreeze, oil and others);

- constant circulation of the coolant in the system eliminates the possibility of overheating;

- durable, mechanical wear of elements is minimal;

- the system is environmentally friendly - there are no emissions of any hazardous fuel decomposition products;

- meets fire safety requirements.

Heating system

When installing homemade induction heaters in a heating system, craftsmen often use inexpensive models of welding inverters (DC-AC voltage converters). The energy consumption of the inverter is high, so for continuous operation of such systems, a cable with a cross-section of 4–6 mm2 is needed instead of the usual 2.5 mm2.

Such heating systems must be closed and automatically controlled. Also, for operational safety, a pump is required for forced circulation of the coolant, devices for removing air trapped in the system, and a pressure gauge. The heater must be located at least 1 m from the ceiling and floor, and at least 30 cm from walls and furniture.

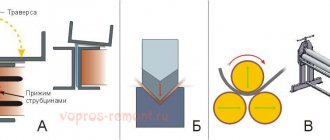

Popular steel casting methods

Steel casting is a process that produces alloys with different chemical compositions. Technologies have been developed where charge, used metal products and cast iron are used as raw materials. The resulting blanks comply with GOST parameters.

The casting process produces products of varying quality. It depends on the manufacturing method. It is important that harmful impurities that make the alloy brittle are disposed of. This happens due to their oxidation, when iron interacts with oxygen.

History and essence of technology

In ancient times, steel was produced in shaft furnaces using the cheese-blowing method. Charcoal was used for this. Iron was mined from ore. At the same time, small pieces of cast iron were used as raw materials. Melting was carried out in crucibles. The quality of the resulting material was high, but low-productivity. However, this is exactly the method used to obtain Damascus steel.

Later, cast iron was processed using critical processing. It was being refined in a screaming throat.

In the 18th century, puddling technology began to be introduced. The starting material was also cast iron. The disadvantage of the technology was low productivity.

The open-hearth production method was developed in the 19th century. It turned out to be so successful that it was used for 100 years. And only then in the 50s it was replaced by the oxygen converter process.

The importance of steel in global industry

Steel is a material that is of utmost importance. A rare design can do without it. If we compare steel production with all non-ferrous metals, then its total output is 90%. Industrialization creates a constant demand for such material. It is in demand in any industry.

No production can do without bolts, nuts, washers or nails. Steel is used in large-scale projects. First of all, these are bridges, where the basic foundation is a metal frame. Aviation cannot do without it. A large amount of material goes into laying the rails. Even if the product is made of plastic or other non-metallic material, it may have a steel skeleton.

Certain grades of steel are used for the production of air ducts necessary for ventilation systems. Sheet steel is used as the starting material.

Characteristics of steel

The basis of any grade of steel is iron and carbon. The amount of the latter varies within 0.1–2.14%. The higher its content, the better the quality of the steel. If the amount of carbon exceeds 0.6%, the alloy is called high-carbon. When the percentage of carbon exceeds 2.14, the material is called cast iron.

When steel is melted, alloying additives are added to it, which changes the mechanical properties of the alloy. These include:

- chromium;

- tungsten;

- cobalt;

- titanium;

- vanadium.