Arc welding: first experiments

Russian academician V.V.

Petrov, who was the first to describe the occurrence of an electrical discharge between two conductors, carefully studied the phenomenon he discovered. He suggested that the heat generated during this process could be used to melt a wide variety of metals. This was the first step towards the creation of electric arc welding, which became an outstanding achievement in electrical engineering. The first attempts to connect metals by applying electric current to them were made in 1867 by American engineer Thomson. He took two pieces of metal and pressed them tightly against each other, after which he passed a low-voltage, but high-power current through this system. The edges of the parts began to melt. At this moment, the inventor had to forge the joint with a forge hammer, after which they were connected.

Almost at the same time, the German engineer Zerner tried to use a carbon electrode to join metals. He placed the workpieces horizontally, after which he brought electrodes to them - two on each side. Now it was necessary to pass an electric current through the entire system, as a result of which the metal became very hot. But the connection still needed to be further processed with a hammer, after turning off the current.

Process description

During electric welding, metal parts are joined together using copper clamps. Electricity passes through the joints, heating and fusing them at the point where the two metal parts meet. The surface where the metals lock and touch first becomes hot and then radiates outward as a seam.

The heat distribution is controlled by ensuring a constant flow of current using a control lever. This ensures that both metals become soft and bond to each other at the same time.

Advantages of electric welding include the fact that this method does not waste unnecessary fuel and ensures precision in joining parts. The heat does not extend far beyond the welding point. This makes it ideal for insulated wires. The ends of each wire can be welded, leaving the insulation.

Although welders can theoretically use up to 50,000 amps of current, they are actually much safer and work with different current levels. This makes the welding machine incapable of electrical shock or shock to a person when using electric welding. Welding can take from a few seconds to tens of minutes. Much depends on the volume of metal structures being connected: the wider the contact area, the larger the scale of work.

Invention of arc welding

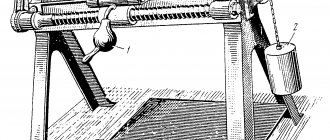

And yet, Nikolai Nikolaevich Benardos is rightfully considered the founder of the arc welding method. The Russian inventor was the first to put forward an idea that later became the basis for this method of metal processing. In 1882, Benardos designed and built a device with which it was possible to qualitatively weld parts in an alternating field and in a gas jet. He used carbon electrodes for arc welding.

Benardos also discovered a method for magnetically controlling an electric arc. Along the way, the inventor developed techniques for effectively using flux and automating the welding process. He also tested the method of resistance spot welding. A number of Benardos' design solutions were patented by him both in Russia and abroad.

Another Russian engineer, Nikolai Gavrilovich Slavyanov, improved the previously developed arc welding method. In fact, he made an independent invention, proposing to use metal rather than carbon electrodes. Slavyanov also built a welding generator and a system that made it possible to regulate the length of the arc. Engineering solutions put into practice by Russian inventors formed the basis of a new welding method, which has not lost its importance in modern production.

Russian electrohephaestus

AND

The inventor of electric arc welding,

Nikolai Nikolaevich Benardos,

was born on July 26 (August 8), 1842 in the village of Benardosovka in a family in which the main profession was military service. Nikolai Nikolaevich’s grandfather is one of the heroes of the Patriotic War of 1812, General Panteleimon Benardos, a Greek by birth, who came to Russia as a boy; father - Colonel Nikolai Panteleimonovich Benardos. Nikolai Nikolaevich spent his childhood on his parents’ estate Novoukrainka, Kherson province. He received his education at home. In 1862, Nikolai Benardos entered the medical faculty of Kyiv University. In 1866 he left the university and in the same year entered the Petrovsky Agricultural Academy in Moscow. In 1867 he went to Paris, where the World Exhibition was taking place in the summer. There he met the famous electrical engineer Pavel Nikolaevich Yablochkov.

Perhaps, not without the influence of Yablochkov, a passion for invention awoke in Benardos. He drops out of his studies at the agricultural academy, gets married and starts building an estate in the Kostroma province, where he decides to closely engage in what he loves - making something with his hands and inventing. Benardos personally participates in the construction of the house, makes stylish furniture, carved platbands on the windows... In the workshops created by Nikolai Nikolaevich, under his leadership, harrows and quick plows are created for a large estate. In the early years, starting in 1865, Benardos's inventions were dominated by agricultural and transportation equipment: improved plows, seeders, a reaper, a firewood implement, steamship wheels, metal sleepers, and much more. In 1873, he began to build a model of his beloved, long-planned brainchild - a steamship on rollers, crossing shallows and avoiding various obstacles along a rail track. In 1877, Nicholas Benardos finally realized his dream. Approaching the sloping shore, the all-terrain steamer began to move on dry land, on wheeled rollers. And the captain on this ship was Nikolai Nikolaevich himself. Tests of the ship were completed successfully, but not a single industrialist was interested in it.

In the mid-1870s, Benardos met the engineer and inventor Andrei Ivanovich Buksenmeister, who in 1878 founded a plant near Kineshma for the production of batteries, coal products and electric arc lamps (now). Friendship with Buchsenmeister undoubtedly contributed to the inventive activity of Nikolai Nikolaevich. The owner of the plant supplied it with electrochemical power sources, electric coals and other necessary materials. Benardos received ample opportunities to experiment with the electric arc and look for directions for the practical use of electricity. Together with Buchsenmeister, he conducted a number of experiments with rechargeable batteries.

The steamer was abandoned, but Benardos was fired up with a new idea. When building the steamship, he had to connect large metal parts. This was done, naturally, by forge welding. But Benardos' workshops did not have large heating furnaces. And he tried to heat the edges with a voltaic arc before they went under the hammer. And sometimes, even before forging, the metal was melted and small sections were connected.

In order to obtain the money necessary to continue scientific and engineering research, Nikolai Benardos was forced to sell a significant part of his land and mortgage the estate. In the end, he leaves the estate to the manager and leaves for St. Petersburg.

With the idea of connecting metals with a voltaic arc, Benardos came to Pavel Nikolaevich Yablochkov in his partnership “Yablochkov the Inventor and Company”. Yablochkov, immediately realizing what great prospects the method of welding metals with electricity could bring, immediately hired Benardos. In subsequent years, Benardos collaborated a lot with Yablochkov. Naturally, at that time he was most fascinated by the new area of practical application of electricity: he created a candlestick for a Yablochkov candle with automatic current switching, an arc lamp, a machine for insulating cables, a machine for braiding wires, commutators, rheostats, including a water rheostat.

Russian engineer, inventor of electric arc welding Nikolai Nikolaevich Benardos

Photo: gettyimages.ru

In 1881, as an employee, Nikolai Nikolaevich went to Paris to the International Electrical Exhibition. To prepare the exhibition, Yablochkov assigned Benardos to the experimental laboratory at the Electricien magazine. Its co-director turned out to be an old acquaintance of Benardos from St. Petersburg, Russian citizen Nikolai Ivanovich Kabat. In this laboratory, Benardos began experimenting with lighting technology and began improving batteries. Just then, at Kabat, he invented new types of corrugated batteries, for which he did not take a patent due to lack of money. Out of generosity, Benardos gave the idea to Kabat, who made 800 thousand francs from it. Research on joining metals using a voltaic arc, which Benardos began on his estate and continued in St. Petersburg, in the Yablochkov Partnership, Nikolai Nikolaevich practically completed abroad. Batteries, first developed for electric lighting and then for electric welding, were a remarkable invention. Already in 1882, Benardos put electric welding into practice - “a method of connecting and separating metals by the direct action of electric current,” he called this method “electrohephaestus” and first demonstrated it in Kabat’s workshop.

Foreigners who came to Kabat’s workshop to look at the “electrohephaestus” predicted millions for the inventor, because with the help of the new method it was possible not only to connect, but also to cut metals and make holes. There was no end to those wanting to watch Benardos cut the rails.

Benardos is in a hurry to return to Russia. He doesn’t have any money yet, but he’s bringing with him his invention, which has global significance! Benardos's financial situation is worse than ever. For non-payment of debts, the estate he built was sold under the hammer. Even earlier, the forests he inherited from his mother in Yuryevets district were sold. Nikolai Nikolaevich returns to St. Petersburg. His name is already widely known not only in Russia, but also abroad. Yablochkov’s enterprise continues to finance his experiments, but Pavel Nikolaevich does not yet recommend taking out a patent - the method seems still crude and not sufficiently developed. And it’s too early to talk about industrial welding. Here Benardos accidentally meets the wealthy merchant Olshevsky, owner of apartment buildings in Warsaw and St. Petersburg. Since Benardos does not have the money to pay the patent fee, Olshevsky offers his own financing, but on the condition that he becomes a co-owner of the patents. Benardos agrees. And in all patents, except the Russian one, Olshevsky is listed as a co-owner of Benardos’ invention.

Benardos filed patent applications for his method in 1885 and received patents for the invention in Russia, France, Belgium, Great Britain, Italy, Germany, Sweden, Norway, Denmark, Spain, Switzerland, the USA and Austria-Hungary. Olshevsky advised the inventor to break with the Yablochkov Partnership, where Benardos was required to continue the experiments. And in the same 1885, the Electrogephaestus partnership was founded. By that time, electric welding had attracted the interest of major foreign scientists, some of them came to St. Petersburg to get acquainted with the outstanding invention.

Unfortunately, Benardos realized too late that the members of the board of “Electrogefest” had already taken possession - sometimes by cunning, and sometimes by outright deception - of all his material privileges. And then it turned out that back in 1881, Auguste de Meritan received a French patent for the electric welding method. The owner of a similar patent, received in England back in 1849, turned out to be the American Stead. And besides them, here and there, newly-minted false inventors of welding appeared... on paper.

But nevertheless, it was the method of electric arc welding by Nikolai Benardos that was used for the first time in the world in 1887–1888 in the Roslavl workshops on the Oryol-Vitebsk Railway to repair locomotive and carriage wheels, frames, gratings, etc.

Within five years, the Benardos method spread throughout Russia: in addition to the Roslavl workshops, it was used in the railway workshops of Voronezh, Rostov-on-Don and other cities, at the Kolomensky plant in Golutvin, at the Gouzhon plant in Moscow, at the Nevsky Machine-Building Plant, at the Lessner plant in St. Petersburg, etc. Abroad - in England, France, Germany, Austria and a number of other countries where the Benardos method was used for a wide variety of repair work and for the manufacture of new products. Benardos invented not only the carbon arc welding method, but essentially all the main current methods of electric arc welding. His designs included many ingenious gadgets and devices, including several systems of automatic carbon electrode welding machines, automatic metal electrode welding machines, and carbon and metal electrodes in a wide variety of shapes and combinations.

In an effort to increase the heating area and create a protective environment in the welding zone, Benardos used gas jet welding. “Working with an arc together with gases,” he wrote, “serves to increase the heating field and heat the surfaces of the metals being processed.” But this Benardos method found application only almost half a century later and was unreasonably called by the Americans “Alexander’s method.” Currently, jet welding of various gases - argon, nitrogen - is used in many branches of technology. In an effort to automate the process, Benardos pioneered the development of several systems of automatic devices for both metal and carbon electrode welding. These devices became the prototypes of modern automatic welding machines. One of them was adapted for welding longitudinal seams with a metal electrode.

Patent for the electric arc welding method "Electrohephaestus", issued to Nikolai Benardos and Stanislav Olszewski on May 17, 1887

But by 1889, various businessmen, who had practically seized the outstanding Russian invention into their own hands, deprived Benardos of the opportunity to continue working on the development of the electric arc welding he had created. However, Benardos could not help but invent! He developed a method of coating iron ships with copper; drawings of the corresponding device were also presented by him in 1892 in St. Petersburg at the IV Electric Exhibition.

In addition, during this period he created propellers, including rotating ones, steel armor for ships, batteries with sponge lead plates, an electric boat, a plow, an “electric fertilizer”, which was the first to use electric current for cultivating soil, and much more. other. He wrote brochures about the project of a shallow-crossing steamship (1890) and the project to supply St. Petersburg with cheap electric current for lighting and traffic (1892).

The first brochure describes a steamship (built and abandoned long ago) with special roller wheels, on which the steamer could, when leaving the water on the shore, bypass places inconvenient for navigation along specially laid rail tracks. The second brochure contained a project for a hydroelectric station on the Neva at the Ivanovo rapids and a power transmission line to St. Petersburg. But Benardos’s favorite brainchild always remained electric welding, to which his thoughts returned more than once. Thus, in 1891, Nikolai Nikolaevich developed a “method of cupola electric soldering, electric casting and electrodeposition of metals.”

Each new invention had to be developed, then patented and fees paid for many years. And Benardos had a great many inventions and patents. This is where all the money went. Nikolai Nikolaevich Benardos worked with equal passion both on grandiose projects and on ridiculous little things. He invented a tin can, a tricycle, a screw cap, digital locks for safes, and portable folding balconies for washing windows... He invented an electric fertilizer and developed a method for fertilizing fields with his “electric cultivator” and other electric cultivators. He invented an electric cannon, which could be used in coastal defense on large ships and fortresses. It’s simply impossible to count everything. Back in 1890, Nikolai Benardos published his “Project for a method of repairing, transporting and raising the Tsar Bell.” He suggested welding the gigantic piece that had fallen off the bell using “electrohephaestus,” then loading the bell onto a special platform and delivering it to Vorobyovy Gory. The Tsar Bell was supposed to be raised using hydraulic jacks to the Tsar Bell Tower, the design of which he also developed, where on one floor there would be a temple, and on the other a museum dedicated to the miraculous rescue of the royal family during the crash of the imperial train near Kharkov in October 1888. In the early 1890s, this project was widely discussed in the Moscow and St. Petersburg press, but remained unimplemented.>

Unfortunately, almost none of Benardos’s projects, with the exception of the “electrohephaestus” and a few other inventions, found practical application. Perhaps because ideas such as a hydroelectric station on the Neva near St. Petersburg or a movable platform for crossing pedestrians across the street seemed too fantastic to everyone. Among Benardos's inventions you can find a high-speed steamship with a balloon, a brake for railways, a water ski with a mechanical engine and a reaping machine, metal sleepers and a washing machine. And most of these inventions have been forgotten.

In 1898, Benardos moved to the city of Fastov, Kyiv province: he could no longer afford to live in St. Petersburg. And yet, with his last money, in 1899 he patented a special method for preparing sponge lead for battery plates, and in 1900 he received the privilege for a method for making harrows by stamping from sheets. In 1899, the Electrotechnical Institute in St. Petersburg awarded him the title of honorary electrical engineer, putting his invention on a par with such an outstanding invention as Alexander Popov's radio.

Despite universal recognition, Nikolai Nikolaevich still lives in poverty. After much hesitation, he decides to ask the council of the Russian Technical Society to grant him a lifelong pension. Three years later, on September 21, 1905, Benardos died. Not a single magazine responded to his death; Russia was then experiencing its first revolution. But the electric welding created by Benardos, perhaps, became the best monument to its inventor.

Electric welding at home

Electric welding is a process for effectively permanently joining metal parts. Today it is actively used to create mesh mesh, all types of frames, tanks. People with the appropriate skills can create canopies for roofs, openwork fences and other things needed in everyday life in their own backyard. This is why many people are concerned about learning to work with electric welding.

Recommendations:

- Clean welding surfaces thoroughly. It is important that they are free of rust and dirt.

- Insert the electrode into the special welding holder and form an electrical arc. To do this, it is necessary to cause current movement in the welding area.

- With an electric arc, it is necessary to make a gap between it and the connecting surface. It should be noted that the size of the gap should not vary from three to five millimeters. Otherwise, the arc will be periodically interrupted, which will lead to deterioration in the quality of the weld.

- The rod should be held at an angle of about 70 degrees. However, this value can be changed to improve the comfort of electric welding.

- Follow safety rules.

Electric welding requires compliance with the following safety rules:

- The wires that are connected to the power source and arc welding must be effectively insulated, and the body of the welding machine must be grounded. The use of a housing and additional electrical equipment is recommended.

- It is recommended to use special power switches in power supplies. During idling, they break the welding circuit and apply a voltage of 12 V to the holder.

- Welding work should be carried out wearing good, dry gloves and clothing. Please note that if you plan to work in a confined space, you should worry about preparing rubber mats or rubber galoshes.

- If several welding machines are used simultaneously, they must be positioned so that the distance between them is at least 0.35 m (the optimal passage width is about 0.8 m).

Great attention should be paid to these rules. After all, electric welding is a rather traumatic process . But any disaster can be avoided if you carefully study the issue and approach the matter responsibly.

Types of electric welding

Welding materials are an effective way to join metal structures together without the use of fittings. MIG, TIG and hand welding are the three types of electric welding. Arc welding is one that is achieved by flowing an arc of electricity between an electrode and a work surface. Most methods involve the use of a shielding gas to ensure smoothness and prevent contamination at the welding point, improve weld quality, and stabilize the arc of electricity between the work surface and the electrode.

MIG

Gas metal arc welding is called MIG. This method is often used in steel processing. This process essentially involves melting aggregate onto a work surface. Using this method, welders can make longer welds without interruption—there are no more interruptions required than with conventional welding methods.

The most common shielding gas used in this type of electric welding is argon or an argon mixture containing oxygen or carbon dioxide.

However, there are several potential disadvantages here too. First, it may be difficult to create an arc to begin the entire process. Secondly, welds produced by this method are prone to severe oxidation.

GIA

Gas tungsten arc welding, called TIG , is a welding method often used when working with magnesium, aluminum, titanium, nickel and copper alloys. TIG welding can be done with or without fill. The welds here can be significantly smaller than MIG welds because the heat at the TIG welding points is better defined.

One of the disadvantages of this type of welding compared to MIG is that it is more resource intensive in terms of time spent. But this type of welding is one of the cleanest, since no splashes are formed during the process. Argon combined with helium or hydrogen is often used as the shielding gas for this type of welding.

Manual

One of the first methods, shielded electric arc welding of metals, is also referred to as manual welding. This method is ideal for use on bridges, steel structures, pipelines, tractors. Often used for external welding, since natural factors, such as rain, will not damage the integrity of the seam. Hand welding can be difficult and is only recommended for experienced welders.

Connecting pipes using electric welding

Electric welded metal fittings

Electric welding fittings are devices that help connect two parts of workpieces. There are two formats: threaded and welded. Threaded fitting ends - threads are made on the inside and outside of the fitting. The fitting also has a chamfer, which makes it easier to make an electric weld.

Many of these attachments are attached to the part using two elements: the knee and the butt. In the first option, the diameter is larger than in the second, and the second, as a rule, coincides with the part being welded.

Electrical phytic polyethylene

These parts make it possible to increase the electrofusion of the parts being connected . Typically, polyethylene accessory fittings are used for polyethylene water pipes that are designed for low pressure systems.

HDPE fittings are installed on pipes using a butt or overlap. The elements are held in a special holder. The connection and tube are installed, then heated, inserted into the fitting.

It is noteworthy that both variants of electric welding are based on chemical action - the destruction of molecular chains of polymers at a temperature of 170 degrees Celsius and the formation of new ones in the process of strengthening the plastic.

Cohesion and electropollination

Modern electrical technology has reached a level where it is easy to do without bulky, difficult to use and outdated equipment.

The outer shell and its fitting melt, and when the temperature drops, a new polymer chain is created. As a result, high-quality electric welding of polyethylene pipes is guaranteed, which can be safely used for both home systems and industrial pipelines.

These fittings have the following advantages:

- they connect pipes with a diameter from 20 to 400 mm;

- the connection is internally installed and can withstand high pressure;

- they are inert to all chemicals and thus safe even for water;

- withstand any pressure surges.

Fittings have a wide range - from small to large diameters. They can even be used in large chemical plants.

You can use a transformer to install the fittings.

How to prepare electric pipe welding

- Preparation: welder, workpiece, connecting element, transformer in full readiness and integrity.

- Pipe at right angles.

- With chamfered edge of the part, for precise cutting.

- The pipe passes into the fitting and fixes the place where it was previously marked.

- Degrease parts.

- After connecting the welding transformer to the power source, form a weld joint.

- The welding machine is turned off and the warm-up mode is turned on for 30 minutes.

- It is important not to move any connection or holder! After turning off, wait until it cools down completely.

- The device is ready for use and further connection!