Scrap metal collectors will be happy to take your old washing machine. But don't rush to please them. You won't get much money for scrap, but if you approach this issue wisely, you can get a lot of useful things for your household. Homemade products made from a washing machine engine will help you quickly de-feather poultry, cut pet food, mow the lawn, and smoke fish and meat. And this is not a complete list of what can be made from a washing machine. Today in the review by the editors of HomeMyHome.ru there are detailed instructions on how to give the “iron heart” of a washing machine a new life.

Parts from a washing machine - material for many useful homemade products

What can an engine from an old washing machine look like?

If you are planning to make homemade products from a used engine, you need to figure out what it is and what it is capable of. In washing machines you can find three types of motors: asynchronous, brushless and commutated. Let's take a closer look at them:

- Asynchronous - can be two-phase or three-phase. Two-phase engines are found in older Soviet-made models. More modern machines are equipped with three-phase. The design of such an engine is extremely simple; it can reach speeds of up to 2800 rpm. The working engine removed from the machine just needs to be lubricated - and it is ready for new exploits.

Such motors are characterized by quiet operation. Their only drawback is their impressive dimensions.

- Commutator – you will find this type of motor in the design of most household appliances. Such devices can operate from direct and alternating current, have compact dimensions and a controlled speed. The only drawback of such an engine is the brushes that wear out, but these parts can be replaced if necessary.

It must be admitted that, in comparison with an asynchronous motor, such a motor is noisier. In addition, it often overheats and even sparks

- Brushless direct drive is the most modern motor from the Korean manufacturer. You will find it in modern washing machines from LG and Samsung.

Such models are the most compact.

They are characterized by wear resistance, simplicity of design and high efficiency. Now that you can determine the type of motor, all that remains is to decide where you can use the motor from the washing machine.

Motor connection

To lay out the winding wires, you will need a multimeter. It would also be a good idea to prepare side cutters or pliers for stripping the wires. The list of other tools depends on what kind of equipment will be assembled for the engine.

Connecting the unit to alternating current.

- We determine the pairs. We apply one probe to any core, and use the other to check the rest. If the multimeter gives a signal, it means a pair has been found.

- We find the resistance indicator of the two windings. The highest value indicates the trigger pair.

- Different tandems are connected in pairs and then connected to a common 220 V network.

- The shutdown button can be installed on the starting winding cable.

Sometimes it is necessary to reverse the direction of rotation of the motor. It is enough to simply change the outputs of the starting winding.

We properly disassemble and decide what can be made from parts of an old washing machine

Disassembling a washing machine is a leisurely task. After working with water, a salt build-up may remain on the parts; it must be carefully removed so as not to damage the parts during removal. What can be made from an old washing machine? A motor will be useful for homemade projects - it will become the basis for many devices. The drum will also come into play. It is usually made of stainless steel. All pipes must be disconnected from the drum. A loading hatch may also be useful. In addition to these parts, do not rush to throw away springs, counterweights and body parts.

For those who are versed in electronics, you may need a circuit board - it can easily be used to find spare parts for repair work if necessary.

Case products

The washer body can be used to make:

- a box for various small items or tools;

- porthole window;

- lockable dog house;

- flower beds for various plants.

Box for various small items or tools

Any semi-automatic machine with a horizontal load is suitable for making such a box.

To get a box from it, do the following:

- remove the top and back covers;

- remove the motor and tank with drum;

- measure the interior space;

- Make shelves according to these dimensions, taking into account the door protruding inward;

- in the upper part of the shelves, install a pair of 3-5 W lamps and connect them to the switch in the door lock, to reduce the load on the switch, use a relay;

- put the machine on its feet;

- insert the box inside it, secure it and replace the back and top covers;

- lay hidden wiring to the nearest outlet.

In the same way, you can make a minibar, then instead of light bulbs, install a New Year's LED garland with a controller. When the door opens, the garland will begin to flash, creating a unique play of colors.

Porthole window

To make such a window, you will need the door of a semi-automatic washing machine with horizontal loading and a part of the body with hinges and a lock.

The advantages of such a window are its unusual appearance, somewhat reminiscent of a ship's porthole, and its tightness when closed due to rubber seals.

To make such a window, disassemble the washing machine, taking out all the insides, then use a grinder to cut out the part of the body with hinges and a lock .

The cut piece can be of any shape, however:

- the round one looks more stylish, but cutting it out will require more effort;

- The square one is easier to cut, but it looks less interesting.

Remember, the size of the window opening into which you are going to embed the porthole must be larger than the rubber door seal. After installing such a window, carefully seal all cracks and voids with foam, but do not stain the sealant.

You can decorate the inside of such a window and hide the cut edges of the frame using wooden or plastic decorative overlays.

Closable dog house

The washer door and part of the frame with the lock and hinges can be used to create a lockable kennel for a small to medium sized dog. To do this, it is enough to cut out part of the body with the door and nail it to the booth in the area of the manhole.

Now you can close the dog so that it does not scare guests or dig up flowers in the garden. The animal's intelligence is enough to grasp the connection between digging up flowers, the owner's dissatisfaction and the inability to leave the booth.

Flowerbed-pot for various plants

The body of a washing machine, both semi-automatic and activator type, is a good flowerbed. To do this, remove all the contents from it and remove the door, then drill several dozen drainage holes with a diameter of 8–10 mm in the back wall.

Lay the body with the loading hole up and load it with a layer of crushed stone with a fraction size of 20–50 mm , then a layer of sand and fertile soil in which any plants can be planted. If you paint the body, the flowerpot will become even more interesting and attractive.

Do not use such a flowerpot without a layer of stones and drainage holes, otherwise you will not be able to properly regulate the level of soil moisture.

On the surface, under the influence of sunlight, the earth will dry out, while below, next to the back wall, excess moisture will begin to accumulate, which will lead to the appearance of pathogenic microflora and damage the roots of plants.

In addition, excess moisture will negatively affect the condition of the metal body of the washing machine, which will cause corrosion processes to begin in it and soon rust will eat through it so much that it will be visible even from the outside.

How to make a sharpener or grinding device from a washing machine engine

A sharpener is one of the most popular tools for the home. It can be used to sharpen garden tools, household knives and scissors. If you don’t already have one, buy it at any tool store or make a sharpening machine from a washing machine. The most difficult part is how to attach the sanding wheel to the motor. The easiest way is to buy a ready-made flange. It looks something like this.

Flange for motor

You can machine a flange from a metal pipe of a suitable diameter; most often, a tube with a cross-section of 32 mm is suitable. You need to cut a piece 15 centimeters long from it, this is quite enough to fix the emery. The flange is secured to the motor shaft by welding or a through bolt. The video describes in detail how a homemade washing machine sharpener works:

How to choose a good dough mixing machine for your home - rating of the 10 best models

Last updated July 16, 2020

The quality of the kneading mainly depends on the type of “mixer” and the set speed

What is a test kneading machine and how it works

A dough mixing machine is an automated device that, by operating from an electrical network, independently prepares yeast, puff pastry, yeast-free and many other types of dough. The basis of its design is a rotating element and a nozzle, which can have an S-shaped, Z-shaped, spiral or convex corolla shape.

With the help of dough mixers, you no longer have to stand over the table for hours kneading stiff dough.

The type of attachment is responsible for a specific function, as a result of which the machine has the ability to knead dough according to a specific recipe.

Almost each of the device models has up to ten speeds. After starting the machine, the process of kneading the dough in a special bowl (bowl), which is part of the household appliance kit, begins.

All you have to do is add all the necessary ingredients into the container, depending on the type of dough you choose.

The operation of the machine depends on the installed motor and the kneading lever, which rotates the attached attachment. Please note that the implementation of the dough mixer is carried out differently depending on the type of device.

Types of dough mixers and features of their design for different doughs

Each home dough mixer has individual functions, of course, if it is not a universal model. Depending on the type of design of the nozzles, the devices received their name, and each of them performs strictly individual tasks.

For reliability, kneading attachments can be lubricated with vegetable or butter, just a little, because the product can spoil the real taste of the dough.

Horizontal dough mixer - easy to use

If kneading steep unleavened dough by hand for dumplings, dumplings or shortbread products is quite difficult, then using the horizontal design of the mixer you will cope with the preparation twice as fast. The mixing blades are positioned horizontally at high speed. After the process is completed, the dough tank slides out for easy removal of the product.

The classic models of dough mixers are 5-liter units that are capable of kneading a sufficient amount of raw materials for confectionery products

Planetary dough mixing machines - the best multifunctional model

This device has different possibilities for preparing dough. Thanks to the unique design of the working mechanism, it is possible to mix a wide variety of confectionery bases. All this is achieved by simultaneous movement of the nozzles around their axis and the bowl. Having set a certain mode, the housewife may not control the process of preparing dough for pancakes, pancakes and other types of baked goods.

A spiral dough mixer for home will saturate the dough with oxygen

The design feature of a spiral type dough mixer is that the nozzle and bowl move simultaneously. This creates an unusual air mass. Intensive mixing of all ingredients with a spiral blade eliminates the appearance of dry flour lumps and poorly mixed products.

Features of a household dough mixer

The dough mixer is capable of preparing various types of dough, including confectionery compositions: cream, mousse, mastic, minced meat and other types of sauces. Due to its functionality, this device has become more often used in the kitchen to speed up baking. The universal blades operate at three speeds and perform kneading in a short period of time.

How to choose a dough mixer for use in your home kitchen

The choice of the best dough mixer model can be made solely on the basis of perceived personal needs. You must initially determine for yourself:

- what tasks the device will mainly perform;

- what is the optimal bowl size, respectively, and the amount of dough required at one time;

- Availability of several modes and speeds. When such options are available, the device will get the job done faster and will be able to perform multiple tasks;

- availability of additional equipment (timer, indication, sound signal).

For yeast dough, it is better to add only warm ingredients to the bowl.

GOOD TO KNOW!

Despite the shortest time required to knead the dough with the device, it turns out unusually airy and aromatic, of course, provided that you put in the correct amount of ingredients.

Having decided on the functions of your dough mixer and the type of dough you frequently use, you should pay attention to some of the nuances of each, which are described below.

The best models of dough mixers for home, according to the editors of Tehno.guru with prices

Quality and price, appearance and versatility, as well as the availability of additional features - this is all that worries every buyer when choosing a household type dough mixing machine. In our rating you will certainly find the highest quality models at reasonable prices.

1 place. Kenwood KVC5100T - suitable for preparing complex dishes

The kitchen dough mixer model is available in two colors: silver and white, but this does not prevent it from being at the peak of popularity. Using a set of special attachments, the device will help you create both thin and medium-thick dough. The device is also designed for whipping various sauces and confectionery mincemeat.

| Power, W | Dough container volume, l | Number of speeds | Control method | Number of slots for nozzles |

| 1100 | 4,6 | 6 | Touch/electronic | 2 |

The approximate cost for the model is 30,000 rubles.

Price: ₽ 30,000

2nd place. Useful dough mixer for liquid dough - Gastrorag QF-5W

Having this type of household appliances in your home, you no longer need to get up several hours earlier to prepare a delicious and complete breakfast. For example, if you want fragrant and tender pancakes with a cup of coffee, you can use the Gastrorag QF-5W design, which will perfectly knead the batter in 5-7 minutes.

| Power, W | Capacity volume, l | Bowl type | Number of nozzles, pcs. | Noise level, dB |

| 500 | 5 | Removable | 3 | 30 |

Due to the ability to change attachments, you can prepare any type of dough, and the design of the device is completely safe for humans.

Price: RUB 23,640

3rd place. Dough mixer for yeast dough Gemlux GL-SM5 spiral type

This dough mixing machine is designed specifically for preparing viscous yeast raw materials for baking. The device is easy to use, as it is equipped with a removable bowl (bowl), as well as a folding head. The device has a built-in 30-minute timer, thanks to which you will never miss the moment when the dough is ready.

| Productivity, kg/h | Bowl volume, l | Power, W | Number of speeds, pcs. | One-time batch, kg |

| 35 | 10 | 370 | 1 | 8 |

Yeast dough is the main component of many products that we consume daily. So, why not get similar equipment for household use?

Price: RUB 16,890

4th place. Universal multifunctional dough mixer - Moulinex QA5101 Masterchef Gourmet

If you are faced with the task of regularly baking or any other type of culinary preparation from dough, then there is absolutely no point in purchasing a model with a minimum of functions. In this case, it is better to choose a universal food processor with a mixer and a dough kneader.

| Bowl volume, l | Power, W | Number of speeds | Gearbox type | Additional features |

| 4,9 | 900 | 6 | Planetary | Meat grinder, mill, combine. |

The device has a nice design and is quiet and fast. The universal dough mixer is easy to clean after use, as it has a collapsible design. To become more familiar with high-quality devices for kneading dough, we invite you to study our TOP models, which are located in the section below.

Price: RUB 13,990

5th place. BOMANN KM 392 CB - convenient model with pulse mode

The dough mixer model is suitable for a small family. Available in three colors: red, silver and gold. Ideally copes with the tasks, forming a dough of sufficient density and airiness without flaws. The dough mixing machine model is equipped with a protective cover with the ability to add ingredients.

| Power, W | Working bowl capacity, l | Bowl material | Number of speeds | Safety | Type of shell |

| 1200 | 6,3 | Stainless steel | 6 | overheat protection | Metal-plastic |

Due to the high engine power, the unit is considered quite noisy. This is felt when the equipment operates at maximum speed. The approximate price per unit of goods is 10,000 rubles.

Price: RUB 9,999

6th place. Homemade dough mixer for hard dough - Marcato Pasta Mixer

Agree, buying large dough mixers for your home is extremely inconvenient, and sometimes you really want to cook something delicious using hard, hard dough. Unfortunately, there is sorely not enough time to knead it manually, in which case the Marcato Pasta Mixer will be an excellent assistant for you.

| Number of speeds | Bowl volume, kg | Sleeve rotation, ◦ | Additional functions | Types of nozzles | Hull stability |

| 6 | 3,5 | 35 | Overheat protection, quick-release chuck, refilling of ingredients. | Stainless steel whisk, aluminum dough hook. | There are suction cups on the legs. |

An excellent kitchen assistant that will help you prepare dough for dumplings, manti or dumplings in a short period of time.

Price: RUB 9,850

7th place. Bosch MC812W501 - model with professional design

The device is distinguished by the presence of a built-in juicer and chopper, of course, not counting the main function of the dough mixer. The device will quickly cope with cutting vegetables into cubes for rolling and, if necessary, whip up thick cream for a multi-layer cake.

| Number of bowls | Bowl volume, l/l | Power, W | Safety | Noise during operation | Possibilities |

| 2 | 3,9/1,5 | 1000 | The engine does not start if the parts are not assembled correctly. | Minimum | Mixer, blender, Juicer. |

All components of the device are easy to remove and quickly wash, and do not require complex maintenance. The average price for a model is 10,500 rubles.

Price: RUB 9,575

8th place. FIRST AUSTRIA FA-5259 - strong and stylish dough mixer

This device is considered one of the most popular and in demand among housewives who love to bake. It will help you prepare thick and not very thick dough, puff pastry and yeast dough, as well as a lot of other ingredients. The device deserves the right to be called luxury.

| Power, W | Bowl volume | Bowl type | Output dough, kg | Set of nozzles |

| 1200 | 6,5 | Stainless steel | 2,5 | 3 |

Price: RUB 9,290

9th place. Kitfort KT-1343 - compact but functional dough mixer

A great item that every home needs. Based on the results of its testing, it can be noted that it can easily cope with kneading dough of moderate thickness, and will also create an oxygen-rich cream for sweet confectionery products. By purchasing a device, you are making a profitable investment.

| Power, W | Bowl volume, l | Availability of turbo mode | Number of speeds | Type of shell |

| 250 | 2,5 | Yes | 5 | Plastic |

An excellent machine that is suitable for all cases of preparing breakfasts and pastry flour desserts.

Price: RUB 7,990

Which model of dough mixer is better to buy for home: review of the best device from the editors of Tehno.guru

Taking into account all the capabilities and functionality of the declared models of dough mixing machines and identifying all the advantages, it is worth highlighting one model that should be in every home where they like to tinker with dough. This device is Kenwood KVC5000T. It is approved by many users and experts.

Much depends on the quantity of ingredients, so simply whisking with a whisk or attachment is not enough

Thanks to an individual idea in the development of the mechanism, the dough mixer is capable of preparing preparations for any baked goods, including dishes such as manti, khinkalia, dumplings and other products based on dough. You can find out about the details of the device of this model in our rating, where you can study the technical parameters of the dough mixing machine.

Do-it-yourself dough mixer: detailed video instructions

It happens that a dough mixer is needed on the farm very urgently. In such situations, it is necessary to acquire an automatic unit, but if it is inconvenient to buy a dough mixer right now, therefore, you will have to come up with a design from what is at hand. Therefore, pay attention to the video below, which describes in detail how and from what to make a homemade device.

Perhaps you have information about the best quality dough mixers or models that you have been using for many years. You are welcome to comment below the article. We welcome feedback and will definitely answer all questions.

Making a wood lathe from a washing machine

What else can you do with the washing machine motor? One popular idea is a wood lathe. Let's look at the step-by-step process.

| Illustration | Description of action |

| To firmly fix the engine on the workbench, make fasteners from a metal angle. To do this, drill holes for fixing to the motor legs and table. | |

| To fasten a wooden part, you will need a flange fixed to the motor shaft, and these are the studs made from ordinary bolts with cut off heads. Screw these pins into the base. You will need 3 studs. | |

| The motor is fixed to the table with self-tapping screws and to the metal part with bolts. | |

| The opposite end of the wooden part is attached with such a device. It consists of a screw with a loop, two wooden stands perpendicularly fixed to the corners. | |

| This wooden part must be movable so that different workpieces can be used. For mobility, it is mounted on a threaded stud with bolts. | |

| To control the motor you will need a power supply. You can use one of the computer units. You will need to install switches to adjust the rotation speed. | |

| How to connect a motor to a power supply in animation. | |

| To guide your tools, make a tool rest. It consists of two wooden parts and a metal corner. All parts are movable due to fastening with one bolt. | |

| The lower part of the tool rest is rigidly fixed on the workbench using self-tapping screws and corners. | |

| The workpiece is fixed on the machine on both sides: on the left - on studs, on the right - on a bolt with a handle. To fix it in the workpiece, you need to drill the corresponding holes. | |

| To work, you will need sharpened tools - cutters. | |

| Final sanding of the workpiece is done using a strip of sandpaper. |

What can be made from an electric motor?

This part is often used to make:

- lathe;

- sharpener (grinding machine);

- grinder;

- juicers;

- drive for a manual meat grinder;

- feather removal machine;

- vibrator for concrete compaction;

- lawnmowers;

- feed cutters.

Wood lathe

Due to the insufficient power of the washing machine engine, it can only be used to make a wood lathe. With the help of such a tool, you will be able to carve or polish wood products yourself , which will not only be an interesting hobby, but will also be beneficial for your home.

Some DIYers suggest making a frame from wood, but such a machine will not last long, unlike a metal one, so we recommend making it only from metal.

Materials and tools

To make the machine you will need materials :

- steel pipes of various shapes and sizes;

- nuts, bolts and studs M6–M10;

- a conical stop for the tailstock, you can make it yourself or order it on the Internet;

- pieces of sheet steel 2–6 mm thick;

- a spindle from an electric drill or a pulley from a motor to create a headstock;

- motor driver;

- starting device.

And also the following tools:

- drill;

- Bulgarian;

- welding inverter or semi-automatic (if you decide to make a cone stop yourself, then both devices are needed);

- level;

- protractor;

- roulette;

- set of dies and taps;

- scriber;

- center punch

Procedure

Here is the general procedure:

- Determine the difference between the engine speed and the optimal machine speed; if they differ, then make a gearbox or use a ready-made one. You can increase the efficiency of the machine using an electric motor rotation speed controller; these devices are produced for DC and AC motors.

- Weld a frame from a steel pipe on which the motor with gearbox and headstock, tailstock, and workpiece will fit, so the length depends on the design of these elements and the size of the workpiece.

- Make a headstock; it can be made either from a drill spindle, into which a cutter for metal or concrete with a diameter of 15–30 mm is inserted, or from a pulley, into which 3 screws with sharpened edges are screwed. The headstock transmits the rotation of the part, so take its manufacture as seriously as possible.

- Attach the motor with the gearbox and the headstock to the frame, and the axis of rotation of the headstock should be parallel to the frame, otherwise you will not get good performance from the machine.

- Make a tailstock, its task is to hold the part and form the point of the axis of rotation. In terms of efficiency, the homemade tip and the part available on Aliexpress are the same, but the Chinese product will cost 300–400 rubles, although you will have to wait several weeks for it. Remember, the tip must move along the frame so that you can fix and remove the part, so provide for movement of both the axle with the tip and the entire headstock.

- Attach the tailstock to the frame and make sure that the guide and the tip are on the same axis.

- Set up a support for the chisel.

- Cover the motor and gearbox with any casing.

- Connect the device to a power outlet and ground it.

Forums and videos

Here are links to forums and video reports:

- www.chipmaker.ru.

- forumcnc.ru.

Sharpener

The main problem faced by everyone who converts a washing machine engine into a sharpening machine is related to rapid wear of bearings due to lateral loads .

After all, in a washing machine, the motor motor is connected to the drum, rotor (activator) or centrifuge through a belt reducer, which has its own bearings, which means the lateral load on the electric motor is minimal.

In addition, some washing machines produced after 2000 are equipped with electric motors whose shaft rotation speed exceeds 10 thousand revolutions per minute (rpm).

In this case, the maximum permissible rotation speed of the grindstone is 1500 rpm, and the optimal one is 1000 rpm. Therefore, installing an adapter sleeve with a cartridge for attaching a stone directly to the shaft is pointless - the stone will fly apart and damage the equipment , and perhaps even injure you. To reduce speed, a gearbox is needed.

The easiest way is to make a belt reducer with two pulleys, and the ratio of the pulley circumference should be equal to the gear ratio. A small pulley will be on the electric motor shaft, and a large one on the gearbox shaft, which is also the shaft of abrasive elements.

In order for such a gearbox to work well, consider changing the distance between the pulleys or adjusting the belt tension with an additional roller, because the tension during operation and when replacing the belt is very different.

Since the instrumental base and source materials are different for everyone, we will describe only the general procedure :

- Determine the location of the future machine and how it will be attached to the wall or table.

- Determine the configuration and gear ratio of the gearbox, as well as the number and method of fixing the abrasive elements.

- Draw up a drawing to determine the size and shape of the frame, taking into account the gear ratio and the method of attaching the bearings of its second axis. Don’t forget about the elements for fixing to the table or wall and the support areas in front of the abrasive elements.

- Using this drawing, make a gearbox shaft with support bearings, fasteners for abrasive elements and a drive pulley.

- Make a frame according to the drawing.

- Attach the motor and gearbox to it with the ability to change the belt tension. Remember, both belts must rotate in the same plane.

- Connect the power cord; some motors will require a driver or capacitor.

- Put on and tighten the belt.

- Run it without any abrasive elements.

- If there is no vibration, secure the machine at its permanent location; if there is vibration, determine and eliminate its cause.

- If everything is fine, install abrasive elements.

Grinder

The basic steps required to make a grinder are the same as in the previous section, the only difference is that instead of a sharpening disk you will install a sanding belt .

To ensure its normal movement, attach a feed roller to the gearbox shaft, and also place tension rollers around the perimeter.

A grinder with a washing machine motor can work with belts of different sizes, but the shorter the belt, the less friction loss, which means more motor energy will be spent on grinding or turning the product.

Juicer

This tool can only be made from a washing machine that has a spin function through a drum or centrifuge, so old Soviet washing machines, in which spinning was done manually with two rollers, are not suitable for making a juicer.

The principle of its operation is the same as that of conventional juicers - a grater rotating together with the drum grinds the vegetables or fruits that fall on it, and the crushed fragments fall on the walls of the drum, where under the influence of centrifugal force the juice is squeezed out of them.

Materials and tools

Here are the materials you will need:

- An unnecessary stainless steel pan or a scrap of this material measuring approximately 15x15 cm to make a grater out of it.

- Plastic or stainless steel pipe with an internal diameter of 50–100 mm (the larger the diameter of the drum or centrifuge, the larger the pipe can be used) for the product loader.

- Plastic tube and tap with a diameter of 20–40 mm for draining juice.

- Steel pipes or wooden blocks to create the frame.

- Alcohol or vodka to sterilize the drum and tank.

- Gauze for better filtration of juice. You can do without it, but then there will be a lot of pulp in the juice.

Here is a list of tools needed for such a conversion:

- a set of screwdrivers (flat and Phillips, different sizes);

- set of wrenches;

- metal scissors;

- Bulgarian;

- drill with metal drills;

- a set of cores of different diameters;

- riveter or welding inverter with a carbon dioxide cylinder;

- welding inverter;

- a wooden log or block to fill holes in the grater.

Procedure

Here is the procedure by following which you will turn the washing machine into a juicer:

- Disassemble the washing machine and remove the tank and drum assembly, as well as the counterweights (weights).

- Wash the tank and drum thoroughly, then steam and treat with alcohol or vodka.

- Make a frame that is sufficiently stable from bars or steel pipes. Remember, sometimes the drum or centrifuge creates strong vibrations and can overturn an unstable structure.

- Secure the tank so that the filling opening is directed upward.

- At the lowest point of the tank, drill a hole and cut a drain pipe with a tap into it at an angle of 45 degrees. It is desirable that the drain pipe extends beyond the frame, and the distance to the ground is enough to install a bucket or pan there.

- Make a grater from a piece of stainless steel, the diameter of which is equal to the diameter of the feed pipe (loader).

- Place a grater on a log or block and punch several hundred holes with the thickest core, forming sharp teeth on the other side.

- Attach the grater in any convenient way to the bottom of the drum strictly in the center. If you do not have a semi-automatic machine with a CO2 cylinder, then use a riveter and stainless steel rivets.

- Cut a piece of thick pipe of such a height that the lower edge rises 3–5 mm above the grater, and the upper edge rises 3–5 cm above the top of the tank.

- Make a quick-release fastener with which you will fix the supply pipe above the grater. Remember, while the grater is rotating, the products will bounce off it, hitting the walls of the pipe, so the fastening should provide reliable and rigid fixation, and its removal, for example, to clean the juicer, should take a minimum of time.

- Install the washer motor and put it on, then tighten the drive belt.

- Install a standard motor driver that ensures operation in spin mode. If there is no standard driver, use a purchased one or a homemade one. The best results are obtained by a device that regulates engine speed.

- Connect the structure to the power supply and start the engine, make sure that the drum rotates without vibration, otherwise replace its bearings.

Drive for manual meat grinder

For older people, using a manual meat grinder often becomes a problem, because muscles and joints do not tolerate such loads well. Therefore, a drive made from a broken washing machine will turn a hand tool into an electric one , thanks to which the process of turning meat into minced meat will take place without stress on muscles and joints.

The main problem that needs to be solved for this use of an electric motor is related to the optimal rotation speed of the meat grinder shaft and the possibility of its reverse.

If the engine of old Soviet or foreign washing machines produced 1.5–3 thousand rpm, then the optimal rotation speed of the meat grinder shaft (auger) is 100–300 rpm.

The engines of modern washing machines produce 10–15 thousand revolutions per minute. That is, for electric motors of old cars you need a gearbox with a gear ratio of 8:1-10:1 , and for more modern ones - 80:1-100:1.

The problem is that a belt drive with a 10:1 ratio and a small pulley diameter of 6 cm will require a large pulley with a diameter of 60 cm, which is not always convenient. If a transmission ratio of 100:1 is required, then a six-meter disk will be needed, which is generally unrealistic.

Therefore, they do it in two ways:

- several belt reducers are installed in series, but such a scheme leads to a large loss of power;

- They use a worm gear, that is, a gear wheel and a worm (a shaft with a thread of a certain pitch).

That is, for a worm with a diameter of 2–3 cm with a thread pitch of 2 mm, a gear of approximately the same diameter will be required, so such a gearbox will not take up much space. You can do it yourself, by providing a grease dispenser for supplying lubricant, or you can use a ready-made mechanism from some equipment.

Having found or made a gearbox, make a convenient stand for mounting all the equipment so that your parents can comfortably use such a meat grinder, and close the engine with any casing, leaving only the control buttons outside.

Vibrator for concrete compaction

The main problem that arises when pouring concrete is related to its viscosity, because the thinner it is, the weaker it will be after the concrete stone hardens .

Therefore, due to the high viscosity, air cavities are formed in the pouring, which reduce the final strength of the stone, and it is impossible to fill the voids manually, because you cannot see where they are and what shape they are.

The most effective way to compact a concrete mixture is vibration, which can be created using a vibrator, that is, a device that generates shocks with a frequency of 30–100 Hertz.

To make such a device, you need to solve 2 problems:

- turn the circular rotation of the motor shaft into vibrations;

- reduce the load on the motor shaft to extend bearing life.

The easiest way to do this is with an eccentric connected to the motor through a belt drive, so next we will talk about the general principles of manufacturing such devices, because each has its own set of materials and tools.

Here's the procedure:

- Make a frame from wood or metal; the size of the frame should be sufficient to install an electric motor, gearbox and eccentric shaft on it. Also, provide for the installation and fixation of both pins for sealing at depth and holes for fastening to the formwork.

- Place the eccentric shaft on the bearings, then attach the bearings to the frame.

- Place belt drive pulleys located in the same plane on the motor and eccentric shafts. If the engine speed is too high, install an additional gearbox. Remember, when installing two gearboxes, their coefficients do not add up, but are multiplied.

- Put on and tighten the belt.

- Connect the driver or engine starter.

Remember, the most effective is impact through the formwork, however, this method of compaction greatly increases the requirements for it . If you attach several steel pins to the frame, you can lower them into the concrete and transmit vibration through them.

Lawnmower

Despite the fact that a homemade lawn mower made from a washing machine is much inferior to purchased models in terms of cutting quality and ease of operation, it is suitable for mowing clearings and lawns covered with wild but well-groomed grass.

The basis of such a mower is a plywood or wooden platform with wheels, on which an electric motor with a starting device is installed.

A homemade or purchased knife with 2–4 blades with sharpened edges is attached to the bottom of the motor shaft through an adapter. There is a handle attached to the back of the platform, with which you can push it around the area and direct it in the desired direction.

The main problem that will have to be solved during the manufacturing process of the device is related to protecting the motor bearings from dust particles and cut grass getting into them, because in a washing machine there is no such threat, which means there is no protection against it.

In addition, homemade or purchased knives are not designed to rotate at speeds exceeding three thousand revolutions per minute, so a high-speed motor will need to be connected through any type of gearbox .

One of the options for solving both problems is to lengthen the platform and install a motor and gearbox (belt drive) on its upper part. In this case, only the gearbox shaft comes down from the platform, and its bearings can be closed with any suitable seals, for example, from cars.

Wheels for garden carts mounted on a common (front and rear) axle can be used as a chassis. Thanks to their large diameter (10–20 cm), they will provide the mower with high maneuverability and will easily move through any grass.

You can adjust the mowing height using two platforms , located one above the other, with the wheels attached to the bottom, and the motor and gearbox installed on the top. Both platforms are connected by pipes entering each other, with holes drilled in them for clamps - steel pins.

The advantage of this design is that an additional sliding bearing filled with grease can be installed in the lower platform, this will reduce the load on the main bearings of the gearbox.

If the motor of your washing machine produces optimal speed, then the additional bearing will sharply reduce the load on the main ones, so even without a gearbox such a motor will last for many years.

An adapter for installing knives will have to be ordered by a turner, because it must match the diameter of the motor or gearbox shaft, and also securely hold the knives. Also, be sure to balance the blades before installing them on the mower, and then balance the unit assembly. The less vibration, the longer this garden tool will last.

Feed cutter

Due to insufficient power, the motor from the washing machine is only suitable for making one type of feed cutter - a grater, which does not cut the feed, but rips off the top layer from it like a regular grater.

The disadvantage of this type of apparatus is that it is not suitable for chopping grass or hard products. However, it does a good job with fresh fruits and vegetables . The basis of the feed cutter is a grater disk, the manufacture of which requires stainless steel 1–1.5 mm thick.

Tools and materials

Due to the low power of the motor, the optimal disc diameter is 10–20 cm, so the device will be able to chop fruits and vegetables whose size does not exceed 5–10 cm (half the diameter).

Since all elements of the feed cutter are made of metal, the main tools will be :

- Bulgarian;

- welding inverter;

- drill with a set of drills;

- taps and dies;

- all kinds of wrenches and screwdrivers.

Procedure

Here's the procedure:

- Turn it yourself or order a turner a shaft for the disk with flanges and threads for the fixing nut, as well as two bearings - one in front, the other in the back. The distance between the bearings is 5–10 cm. Choose the diameter of the shaft so that common oil seals from Zhiguli or other inexpensive cars fit it. For example, the internal diameter of the gear selector rod oil seal from the G8 is 16 mm, and its average price is 30 rubles, and you can buy it in every car store.

- Cut a circle with a diameter of 10–20 cm from a sheet of stainless steel, then drill a hole strictly in the center for installation on the machined shaft.

- Using a drill with a diameter of 4–8 mm, drill holes on the disk in increments of 1–2 cm.

- Make a stand from hard wood or metal for forming blades, for which, on a flat surface, make a groove 5–10 cm long and 1–2 cm deep, while the width of the groove is 1–3 mm larger than the diameter of the holes.

- Insert a nail or drill into the hole, then tilt the disk against the direction of rotation until it stops and, placing it in the stand through a mandrel or spacer made of soft metal, strike the drill or nail to push through the stainless steel and form a float tooth. Do not confuse the direction of rotation of the disk, otherwise the feed cutter will not work.

- From sheet steel 2 mm thick, weld a round knife casing, that is, 2 disks with a diameter 3–5 cm larger than the diameter of the knife, as well as a sidewall connecting them 3–5 cm wide and 10–20 cm long less than the circumference of the disk.

- Weld the sidewall to one disk, then install any removable fasteners that would securely fix the second disk to the sidewall, but would not interfere with its removal if necessary.

- In the center of each disk, cut holes according to the diameter of the tubes into which you will insert the shaft bearings. Come up with a way to fix the bearings. These can be either inserts (rings), the outer and inner diameters of which are equal to the same parameters of the outer race of the bearing, attached to the pipe with screws or welding, or anything else.

- Weld tubes with bearing retainers into the holes of the disks.

- Insert and secure the bearings.

- Not far from the center of the removable (outer) disk, cut a feed hole and weld a feed tray to it in the shape of a truncated tetrahedral pyramid or cone (depending on the shape of the hole). The length of the feed tray is 30–40 cm, the expansion angle is 30–50 degrees.

- Weld legs (4 pieces) to the rear disk at an angle of 20–45 degrees to ensure maximum stability, as well as a platform for mounting the engine. Consider the dimensions of the drive pulleys, and for high-speed motors, use a worm gear so that the rotation speed of the grater disc is 100–200 rpm.

- Insert the shaft with the grater disc, then secure it with the outer disc.

- Install the engine and both pulleys with the belt (tension it with the necessary force) or gearbox.

- Connect the motor control device and carry out a test run.

- Place the crushed products in a tray, and collect the finished mass from below into a bucket or other container.

How to make a simple feather removal machine for home use from a washing machine with your own hands

The time of slaughtering a bird is a troublesome stage. This is usually done in the fall, when the ducks and broilers have reached the desired weight, and it is no longer profitable to keep them in the winter. You need to pluck several dozen or even hundreds of carcasses very quickly. You can get rid of hard labor with the help of a feather removal machine, and it’s easy to do everything from the same parts of the washing machine.

The only thing that can cause difficulties is the search for rubber fingers with threads - beaters. You will have to order them, so keep in mind that you need to think about making the machine long before slaughter

The device does not require disassembling the washing machine. It is especially convenient to use machines with vertical loading. You just need to fix the beats in the drum so that they point inward. Before plucking, the chicken carcass must be scalded with boiling water and then simply thrown into a rotating drum. Here's what happens:

Important! To prevent water from getting on the engine of the feather removal machine, you need to protect it with a plastic casing.

And the last point - the feather removal device must be firmly fixed, since the vibration when loading the carcass will be very strong.

Home dough mixer - the best models and tips for choosing and setting them up

Every housewife bakes flour products at home, and smart kitchen appliances can be an ideal assistant for this.

This includes a dough mixer for home use. It is not so easy to choose a device, because you need to know important nuances. Once you try to knead dough with it, you will understand how necessary a dough kneading machine is and how it makes the job easier. It is difficult to knead the dough by hand so that it becomes a soft and uniform consistency, so manufacturers of household dough mixers have made sure that the process of working with the dough does not take much time.

How does a dough kneading machine work?

The kitchen device actually works on a simple principle. First, you should put the necessary products inside the compartment; it acts as a kind of bowl.

Next, the button is pressed and the motor starts. Thus, the machine begins its work and the kneading mechanism starts. He thus moves the dough in one direction and it is processed.

The job of a dough mixing machine is to knead the dough. The kneading lever inside the bowl helps to obtain the required consistency. The dough is kneaded, and after a few minutes it becomes elastic and ready for further preparation.

How to choose a dough mixer

To purchase a reliable kitchen assistant, you should consider a number of factors when choosing it. One of the most important points is the nature of kneading the dough, because it can be continuous and kneaded periodically.

The speed of rotation of the lever itself is no less important; it can also be slow, fast or ultra-fast. A kitchen machine will run fast or slow depending on how powerful its motor is. The minimum power can be about 300 W, and the maximum reaches the limits of 1900 W.

Let's look at what types of dough places there are.

Dough mixer with planetary rotation

The device differs in that with the help of a motor the nozzle rotates twice, first it goes around the bowl in a circle, after which it rotates around an axis. This type of dough mixing apparatus is considered the most popular today, as it has many capabilities in the process of kneading dough.

The set of such a machine includes several attachments, namely, a spatula, a whisk and a hook-shaped attachment. In addition to this, the dough mixer attachment can be supplemented with other useful items for dough. For example, some models may have additional attachments for preparing yeast or protein dough.

Dough mixer rotating in a spiral

In order to decide which dough mixer is better for home use when comparing models, let’s consider this version of the machine. Such a dough mixer is ideal for kneading yeast dough, and, as you know, such dough can be kneaded well only with the help of such a device.

In addition, such a dough mixer will be ideal for kneading shortbread or puff pastry. In these models, the nozzle itself does not move, only the bowl itself rotates. This method of kneading allows you to easily knead the toughest dough.

In such dough mixers you can regulate the temperature of the dough.

Manual dough mixer

This kind of dough mixer for home is considered practical and easy to use. It kneads even the toughest dough without difficulty. Some models also have attachments for kneading pasta. Thanks to various attachments for preparing pasta, you can prepare products of various shapes.

The dough mixer is completely manual; it does not work from the mains. The plastic in such devices is usually of high quality and lasts a long time.

Electric dough kneading machine

The dough mixer, which operates entirely from the mains, is represented by a huge range of models. When choosing a particular model, you should carefully study the characteristics for comparison. The most common models are dough mixers from such manufacturers as Moulinex, Bosch, Kenwood.

In addition, you should also pay attention to the country of manufacture; Germany has long been considered the highest quality; it is in first place in the production of electric kitchen dough mixers.

A less reliable device is considered to be one that was produced in China, but do not take into account the fact that similar units from Bosch can be made in China.

This company is a well-known brand with a big name, so you should confidently buy products from such a manufacturer, even if they are made in China.

But you should think a thousand times about buying a purely Chinese brand. As practice shows, such devices do not last long. Many people choose a dough mixer based on the photo and do not pay attention to its characteristics. Experts believe that the first thing to consider is the power of the dough mixer and its dimensions.

Photo of a home dough mixer

Lawnmower from a used motor

We continue to look for the answer to the question of where we can use the motor from an automatic washing machine. Another original idea is making a lawn mower. For a small area, an electric model connected to a power source with a cord is quite sufficient. The design of such a unit is very simple. You will need to make a platform on four wheels with a small diameter.

The platform can be made of metal or OSB board, plywood and even the body of the same washing machine

The engine is fixed on top of the platform, the shaft is threaded into the hole below, and the knife is attached to it. All that remains is to attach handles and a lever to the cart to turn the power on and off. If you have an asynchronous motor lying around, you will be surprised at how quiet the unit will be, even compared to factory models.

Advice! To prevent grass from wrapping around the knives, you need to slightly bend their cutting edges down.

Video: how to make a lawn mower

Lawnmower

It will come in handy in gardens or summer cottages.

Lawnmower

The manufacturing process is as follows:

- First you need to find the wheels from the cart.

- After this, a metal platform is installed. It is made from a corner of a square profile. A special frame can be made from it, after which the racks should be welded to it.

- For the handle, take a small diameter pipe. The handle is welded to the frame using gas welding.

- Next, a hole is prepared in the platform.

Do you turn off the water tap after washing?Oh yes! No.

- There is a grille in the front part. It is bolted on.

- The engine is attached to the platform so that the shaft fits into the hole. Knives are attached to the end of the shaft by welding.

- To protect the engine from grass, it is covered with a casing. Several small holes should be made in it.

- At the end of the process, the power supply cable is connected.

How to build a generator from an old washing machine

We continue to look at homemade products from a washing machine motor, and the turn has come to the generator. You won't be able to assemble a powerful device, but in the event of an emergency shutdown, you can be well prepared. To turn the engine into a generator, you will have to disassemble it and partially cut off the core. In the remaining part of the core you need to make grooves for neodymium magnets.

The magnets must be placed in two rows with the same spacing

The gaps between the magnets are filled by cold welding. To operate the device, the kit must include a motorcycle battery, a rectifier and a charge controller. Details of the work in the video:

Homemade concrete mixer

If you have started a small renovation that requires, for example, plastering the walls, a concrete mixer will come in handy. Once again, washing machine parts will come in handy.

As a result, you will receive a compact device with low power, which you won’t mind throwing away after the repair work is completed.

As a container for concrete, you can use the same drum with pre-sealed holes for draining water. It is best to use parts from a front-loading machine; there will be almost nothing to redo. To strengthen the body, use a metal corner, and for convenient movement of the concrete mixer, equip it with wheels. The main difficulty in the design is the manufacture of a “swing” for the correct tilt and subsequent pouring of concrete. How to do it correctly in the video:

Juicer

There are two options here:

- Using an old machine with a centrifuge and a washing compartment;

- Remaking a conventional barrel washing machine.

Let’s say right away that the first option is better, since it allows, with minimal modifications, to implement two processes in one device: chopping fruit and squeezing it. To do this, you will need a washing machine in which the activator is located on the bottom, and not on the side wall. Replacing it with three homemade strip steel knives, we get a fruit slicer.

Knife installation diagram: 1. Knife, 2. Shaft; 3. Clamping nut; 4. Washer; 5. Tank bottom; 6. Bearing assembly with oil seal; 7. Activator pulley; 8. Locking screw.

Knife group design

The drain hole of the washing tank must be plugged.

There are few additional treatments for the second unit - the centrifuge. You need to install a stainless steel mesh in it (mesh size 1.5 mm, wire thickness 0.2 mm) so that it covers the side surface of the centrifuge.

After thoroughly rinsing the centrifuge, washing tank, hoses and pump with baking soda, you can make the first load.

The operating principle of this juicer is very simple. The fruits are washed and loaded in small portions (1/2 -1 bucket) into the washing tank (knives must be turned on). After 15-20 minutes of cutting, the engine is turned off and the crushed mass is transferred to a centrifuge (in portions of 3-4 liters). Turn on the centrifuge and squeeze out the juice.

Making a juicer from a barrel washing machine or automatic machine is much more difficult. In a barrel, a homemade centrifuge can become a “stumbling block”. Making it is half the battle; the main thing is to achieve perfectly accurate alignment. Without this, at high speeds it begins to vibrate strongly and it will be impossible to squeeze out the juice.

Here is a drawing of a working sample. The master had to work hard to reduce the runout of the centrifuge (the motor is suspended from the washing machine body on 6 springs). Of these, 3 balance the engine in a horizontal plane, and the other 3 push it upward. The body itself rests on an old car tire, which dampens vibration.

Homemade products from a washing machine engine: circular saw

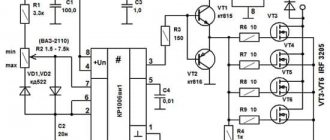

You will be surprised, but a circular machine can also be built based on the motor from a washing machine. An important point in this matter is the additional equipment of the motor with a device that regulates speed. Without this additional module, the circular machine will work unevenly and simply will not cope with the task. Device assembly diagram:

Circular saw diagram

The principle of operation of the device is simple: the engine drives a shaft on which a small pulley is mounted. From the small pulley there is a drive belt to a large pulley with a circular saw.

Important! When working with a homemade circular saw, take care of your hands. All structural parts must be firmly fixed.

The resulting unit will not be very powerful, so it can only be used for cutting boards up to 5 cm thick. How this homemade circular saw works:

Other homemade products based on the sharpener circuit

The above work will have to be done if you want to get other, most diverse machines.

- Wood lathe. The 180 Watt motor from an old washing machine will allow you to process cylindrical workpieces with little effort and slowly. You will definitely need something like a tailstock to support the workpiece. This will protect the motor shaft from lateral loads.

- Drum grinder. For this, a large-diameter wooden cylinder is used, through the center of which a steel rod passes, one end of which is clamped into the engine cartridge, the other is attached to a bearing in a stand. The surface is covered with sandpaper, you can sharpen knives, plane blades if you have devices for maintaining the angle, and perform other operations.

Let us note right away that a sawmill cannot be made from a washing machine engine - there will not be enough torque.

But furniture makers and other home craftsmen will like the idea of making a horizontal drilling device for working with eccentric fasteners.

- The machine is made as described above, with a chuck on the shaft.

- A supporting, guide shelf is made, horizontal, at such a height that the axis of the shaft passes through the center of the end of the chipboard or wooden part.

- A drill is inserted into the chuck, the part is fed horizontally, and the drilling depth can be monitored visually.

To create a location for installing a circular eccentric, it is enough to use a drill, a vertical drilling machine and a milling cutter of the required diameter. This operation does not require high precision. The main, important task of accurately drilling a channel for a cylindrical pin will be performed by a machine made from an engine from an old washing machine.

What else can be made from a washing machine drum: original decor ideas

The drum with its correct perforation is a material for the manufacture of decorative objects. Here are some interesting ideas.

Ottoman with drum base. It’s easy to do – you just need to attach the wheeled legs and make a soft seat

Such a drum can also be turned into an original lamp. If you place a lamp inside, the perforated surface of the drum will cast glare on the walls. Such lamps will look good on the ceiling of the veranda or even on the floor

Bedside tables and tables. Drums with doors from top-loading machines can be used to hide small items.

This is how the drum turns into a cabinet or nightstand

We begin diagnostics and repair of engines

Now let's talk in more detail about repairing the most common faults in electric motors of washing machines.

Diagnostics of electric motors

Correct diagnosis is half the work when repairing

Let's figure out how to diagnose electric motors when they break down. To do this, we need an ordinary multimeter - a device that almost every “homemade person with hands” has. The easiest to diagnose is the commutator motor, so if this is what is installed in your washing machine, you can easily do everything yourself.

So, the first thing we need to do is remove the motor from the washing machine. Here are step-by-step instructions on how to do it.

Removing the engine

- We disconnect the washing machine from the electrical network and move it to a free place so that we can freely approach it from any side.

- Remove the inspection hatch using a screwdriver or screwdriver. For side-loading machines, this is the rear panel, and for top-loading machines, it is the side panel. We unscrew all the screws and move the panel down.

- Next, you need to remove the belt - this is done very simply, just pull it towards you where it fits onto the pulley (a large wheel connected to the drum), and turn it a little. If you've ever changed a chain on a bicycle, the principle will be intuitive to you.

- Then remove the power and ground terminals from the motor.

Bosch 1200 washing machine and electric motor repair

- Now you need to unscrew the bolts that hold the engine. It is most convenient to use a spanner wrench for these purposes.

- All that remains is to remove the engine. It is supported by straight heels, so it needs to be lowered a little and pushed forward, and sometimes considerable effort is required. You can try lightly tapping with a hammer, but it is better not to disturb the engine and remove it with smooth rocking movements.

After the motor is removed, you need to test run it. To do this, we connect the rotor and stator windings in series, and connect an alternating current source with a voltage of 220 V to the remaining connectors.

Attention! You also need to include some kind of heating element in the circuit, for example from a washing machine, or a powerful lamp of at least 500 W. This must be done in order to protect yourself in case a short circuit occurs in the engine. If there is a short circuit, the heating element will begin to sharply increase its temperature, and the lamp will burn brightly.

It would be better if it is possible to power the circuit using a car transformer with a power exceeding 500 W. This will allow you to more clearly control the speed of the running engine. For greater safety, you can include 5 or 10 Amp fuses in the circuit.

If the engine is rotating, then carefully look at the intensity of the sparking at the point of contact between the brushes and the commutator; if it is strong, then there is a high probability that the motor is faulty. Most often, the commutator lamellas, rotor and stator windings, and brushes become faulty.

Continuity testing of individual engine parts

Repairing a washing machine when the electric motor gets hot

If your engine was not producing full power and was making strange noises, and after a test run you determined that it was getting very hot, then the problem is most likely a faulty rotor or stator winding. You can check this using a multimeter, which must be switched to resistance measurement mode.

Continuity of the rotor winding

We successively touch the probes of the device to the adjacent rotor lamellas. Differences in measurements should not exceed 0.5 ohms, and their value should correspond to the data specified in the engine passport, if any. If significant differences are detected, then we can safely state a short circuit between the turns.

In some cases, such a malfunction can be determined tactilely and by smell. Due to the fact that lower resistance causes an increase in current strength, and as a result - overheating, individual lamellas may have a higher temperature than others. At the same time, you will feel a characteristic burning smell.

If during testing the resistance tends to infinity, then this indicates a break in one of the windings.

Continuity of the stator winding

Next you need to ring the stator. The procedure is similar to that described above. First, we measure the resistance between the contact connections of the windings, as shown in the photo above.

Then we look at the short circuit of the windings to the housing (stator iron). To do this, we touch the body with one probe, and with the second we pass through all the contact rings in turn.

Checking the resistance between the winding and the housing

A working stator will have very high resistance values - sometimes hundreds of Mega Ohms.

Determining the wear of the lamellas

The commutator constantly rubs against the brushes

The lamellas are fixed to the rotor using a special adhesive. If the rotor is jammed or there is an interturn short circuit, they may begin to peel off as a result of overheating. A contact break in the rotor section may also occur.

Burrs may appear on the lamellas, due to which the brushes begin to quickly collapse and spark strongly. In addition to rotor jamming, the cause of such a breakdown in machines with vertical loading can be the start of washing with the drum flaps open.

Making a barbecue from a drum from a washing machine, photo examples

A metal grill is a temporary product. Sooner or later it burns out and requires replacement. You can buy a new one each time or use improvised material, for example, a drum from a washing machine. Making this craft from a washing machine drum takes a couple of minutes. The beauty is that oxygen easily enters the perforated container, which causes active combustion.

Kebab coals burn quickly, and the process of cooking meat is significantly accelerated

The metal of the drum can withstand a couple of seasons. Make a comfortable stand for it so you don’t have to bend over, and you’re done. Standard length skewers will fit comfortably on a small roasting pan. If necessary, you can lightly weld a couple of guides.

Checking the functionality of the mechanism

There are machines on sale only with inverter and commutator motors, so we will consider these two varieties, leaving out the asynchronous one.

We are looking for a breakdown of the direct drive motor

The inverter is not intended for home repair. The best option is to try system testing, if your machine model is capable of this.

Self-diagnosis will display a fault code, its decoding and will help you understand where the problem is and whether the services of a specialist are needed.

The testing method and error codes are different for each machine. Before testing, you need to empty the drum of laundry and close the hatch tightly

If you still want to remove the inverter, follow the correct algorithm:

- Disconnect the device from the power supply. It is recommended to wait a few minutes until all elements are completely de-energized.

- Unscrew the bolts and remove the back panel.

- We find the screws under the rotor that secure the wiring and unscrew them.

- Before disconnecting the wires, we take photographs or sketch them, so that later we can correctly connect all power sources.

- Remove the central bolt that holds the rotor. During the process, you need to hold the rotor to prevent rotation.

- We remove the rotor assembly, and behind it the stator.

- Disconnect all wire connectors.

Now you can inspect the engine. It is unlikely that it will be possible to thoroughly test the operation of the inverter. What can be done? Check the integrity of the rotor winding.

The Hall sensor often breaks down in such engines. Whether it is operational can only be determined in a workshop if the part is replaced with a new one.

We carry out diagnostics of the belt drive

To check the collector, you must first remove it from the housing. To do this, remove the back panel, disconnect the wires and unscrew the bolts. It is permissible to pry with a screwdriver in the places where the bolts are attached, where dirt often accumulates and sticking occurs.

Now let's start diagnostics. We connect the wires of the stator and rotor windings according to the diagram. We connect it all to electricity. There is nothing wrong with the device if the rotor starts rotating.

This testing method has its own characteristics: it is impossible to test the operation of the engine in different modes, plus there is a risk of a short circuit from direct connection

To avoid a short circuit, you can connect a ballast in the form of a heating element to this circuit. We connect the ballast from the rotor side. It will begin to heat up, thereby protecting the engine from combustion.

The collector is a structure of several parts and they all require inspection. First in line are the notorious brushes. They are located on the sides of the body. We take them out and inspect them.

If they are worn out, they need to be replaced. A clear sign of such a need is that the engine sparks when rotating. To buy new brushes, take your old ones with you and write down information about the model of the washer.

The next element is the slats. They serve as current transmitter conductors to the rotor. These parts are glued to the shaft and if the motor jams, their detachment is possible.

If you have access to a lathe, it can be used to remove minor flaking. Don't forget to clean off the shavings with fine sandpaper.

Pay close attention to burrs and peelings on the lamellas; they are often the cause of unsatisfactory operation of the washing machine motor.

Now let's move on to the stator and rotor windings. If a short circuit occurs in them, the collector heats up, which causes the thermistor to operate. The result is that power is lost or the mechanism stops working altogether. We test the windings with a multimeter in resistance mode.

The stator is checked in buzzer mode. The ends of the wiring are tested one by one with probes. If there is no signal, the part is fine. You can determine the location of the short circuit by connecting one probe to the wiring and the second to the housing.

The probes are applied to the engine lamella. The display shows less than 20 Ohms - we have a short circuit, more than 200 Ohms - a break in the windings

If the device is silent, this is normal. If a breakdown is detected, you will need to create a new winding to repair it yourself, and this is difficult for a non-specialist.

If you still need to replace the engine, it is usually enough to simply install a new part in place of the old one. After all the manipulations, do not forget to turn on the machine and check its operation.

How to make a good smokehouse from a washing machine drum

The icing on the cake in our matter is the smokehouse. Fragrant smoked meat, lard and fish - what could be better for the table? If you have a tank from a top-loading machine lying around in your shed or garage, consider it a done deal.

It is necessary to cut a hole in the bottom of the tank for the firebox, and weld fasteners inside for hanging food. All that remains is to install the tank on the fireplace, hang the fish or lard, cover the top of the tank with a lid and light the sawdust.

Products need to be smoked for several hours until cooked

It is important that the fuel under the smokehouse smolders and does not burn. It is better to place such a device away from home.

Important! You'll have to keep an eye on this smokehouse. It should not be left for a long time, the fire may flare up, and instead of a smoked product you will get a burnt product.

We hope we have convinced you that you should not scrap your old washing machine.

You can make so many useful things for your home from its parts! If you have experience in making such homemade products or can suggest something tonal - write in the comments!

Tank craft ideas

From a plastic or steel tank you can make :

- heater for summer shower;

- water dispenser;

- expansion tank of the heating system.

To turn it into a heater, do the following :

- paint it black on the outside so that it heats up more strongly under the sun's rays;

- place a summer shower on the roof;

- supply water to it with adjustable flow and a drainage pipe through which excess water will drain;

- connect the faucet with the sprayer;

- plug extra holes;

- Cover the top with a lid to protect the water from dirt.

To make a washbasin:

- raise the tank using a metal or wooden frame to a convenient height;

- connect the tap;

- plug extra holes;

- cover the top with a lid.

To make an expansion tank:

- lift the tank into the attic and connect it to the supply pipe (direct) of the heating system;

- connect a drainage pipe or hose to the hole located at the highest level;

- close the tank with a lid, even the standard lid of the washing machine will do;

- insulate the tank with mineral wool or polystyrene foam.